Description

Application Scenarios

A steel processing plant in Pennsylvania was struggling with inconsistent speed control in their coil winding machines,leading to uneven coil tension and frequent material waste.After installing the CACR-SR30BZ1SS Servopack,the plant saw immediate improvements.The drive’s ability to maintain precise torque control(even at low speeds)resulted in uniform coil tension,reducing material waste by 28%.The CACR-SR30BZ1SS also handled the machine’s frequent start-stop cycles without overheating,increasing production uptime by 15%compared to the previous drive system.

Parameter

Main Parameters

Value/Description

Product Model

CACR-SR30BZ1SS Servopack

Manufacturer

Yaskawa

Product Category

High-Power Servo Drive

Rated Output Current

30A–Suitable for large servo motors(5-7.5kW)

Power Supply

3-phase AC 200-240V,50/60Hz

Control Modes

Position,speed,torque,and interpolation–Versatile for diverse tasks

Feedback Compatibility

Absolute encoder,incremental encoder–Ensures precise positioning

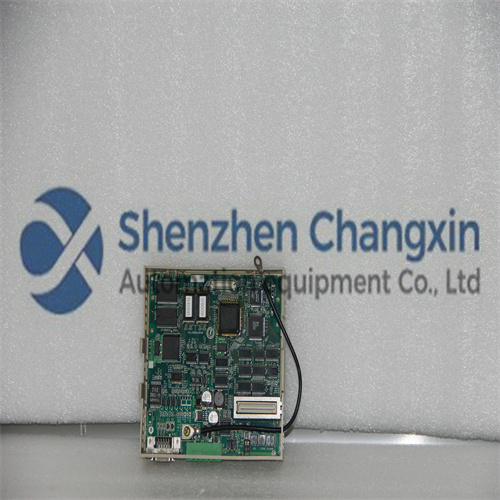

Communication Interfaces

RS-485(Modbus RTU),analog inputs–Easy integration with control systems

Operating Temperature

0–45°C(non-condensing)–Handles higher ambient temperatures

Protection Features

Overcurrent,overvoltage,overload,overtemperature–Comprehensive system protection

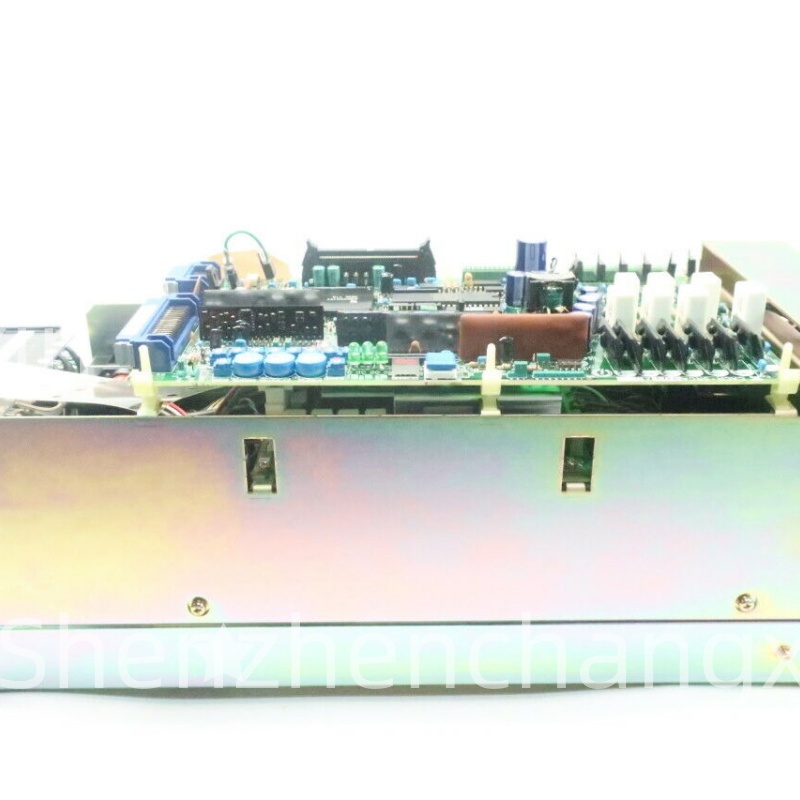

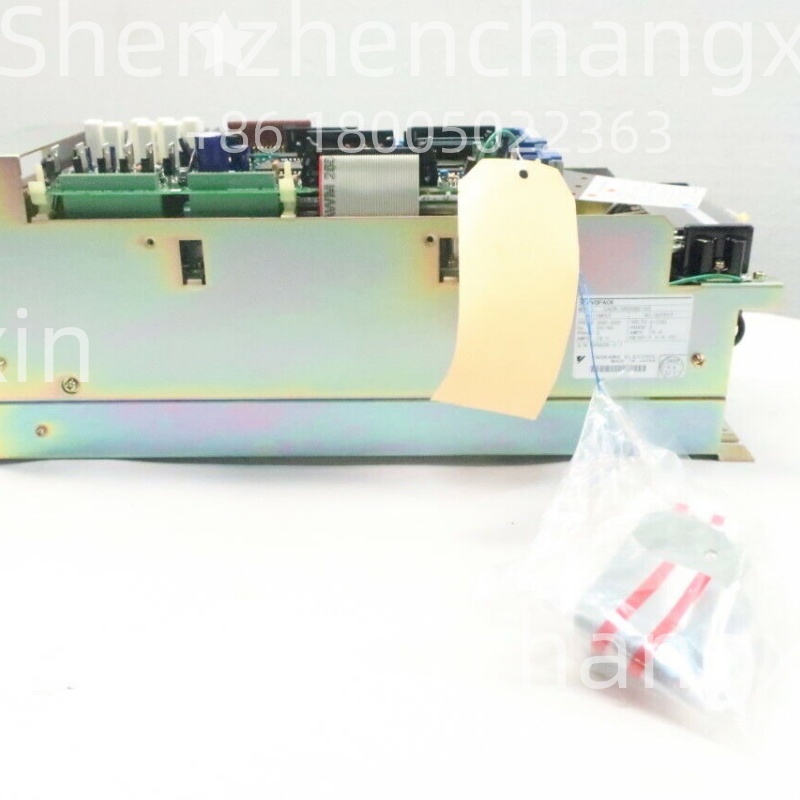

Dimensions(WxHxD)

150mm x 300mm x 220mm–Compact for its power class

Weight

Approximately 5.8kg–Sturdy build for industrial use

Technical Principles and Innovative Values

Innovation Point 1:High-Torque Handling–The CACR-SR30BZ1SS is designed to deliver sustained high torque(up to 300%of rated torque for short periods),making it ideal for applications like heavy material handling and press machines.This capability allows it to handle sudden load changes without performance degradation,a key advantage over standard servo drives.

Innovation Point 2:Advanced Thermal Management–Unlike many high-power drives that require complex cooling systems,the CACR-SR30BZ1SS features a unique heat dissipation design that uses aluminum heat sinks and optimized airflow.This allows it to operate at 45°C ambient temperature without derating,reducing the need for expensive cabinet cooling solutions.

Innovation Point 3:Adaptive Load Compensation–The CACR-SR30BZ1SS uses Yaskawa’s proprietary load monitoring algorithm to automatically adjust control parameters based on real-time load conditions.This ensures stable performance even when handling variable loads(such as different material weights in packaging lines),reducing the need for manual parameter tweaks.

Application Cases and Industry Value

A mining equipment manufacturer in Australia integrated the CACR-SR30BZ1SS Servopack into their conveyor belt positioning systems.The drive’s ability to handle high torque at low speeds allowed precise alignment of ore-carrying belts,reducing spillage by 32%and cutting cleanup costs by$40,000 annually.Maintenance teams praised the CACR-SR30BZ1SS’s rugged design,which withstood the dusty environment without performance issues.

In a paper mill in Sweden,the CACR-SR30BZ1SS transformed the roll stand control system.By precisely regulating the speed of the paper rolls(even under varying tension),the drive reduced paper breaks by 21%,increasing production efficiency.Operators noted that the drive’s user-friendly interface made it easy to adjust settings during production runs,adapting quickly to different paper grades.

Related Product Combination Solutions

Yaskawa SGM7G-55A7A61–High-power servo motor perfectly matched to the CACR-SR30BZ1SS,delivering 5.5kW output with reliable performance.

Yaskawa JZSP-CMP02-01–Cable set designed for connecting the CACR-SR30BZ1SS to Yaskawa servo motors,ensuring stable signal transmission.

Yaskawa SigmaWin+–Software for configuring and monitoring the CACR-SR30BZ1SS,simplifying setup and troubleshooting.

Allen-Bradley Micro850–PLC that communicates with the CACR-SR30BZ1SS via Modbus,enabling centralized control.

Yaskawa CDBR-4060B–Brake resistor optimized for the CACR-SR30BZ1SS in applications with frequent braking.

Siemens S7-1200–PLC compatible with the CACR-SR30BZ1SS for integrated automation systems.

Phoenix Contact QUINT-PS/3AC/24DC/10–Power supply unit that ensures stable power to the CACR-SR30BZ1SS.

Installation,Maintenance,and Full-Cycle Support

Installing the CACR-SR30BZ1SS is straightforward:mount it on a sturdy panel or DIN rail(ensuring proper ventilation),connect the 3-phase power supply,motor cables,and feedback wiring,then establish communication with the control system via RS-485 or analog inputs.The drive’s auto-calibration feature simplifies setup by automatically detecting connected motors and setting initial parameters.

Maintenance for the CACR-SR30BZ1SS is minimal.Regular checks include inspecting cooling vents for dust buildup(monthly)and verifying connections(quarterly).The drive’s built-in diagnostics alert operators to potential issues(such as overloads or voltage fluctuations)before they cause downtime,and replaceable fuses and components make repairs quick and easy.

Our company offers comprehensive support for the CACR-SR30BZ1SS,including pre-installation technical咨询,on-site commissioning,and operator training.We provide a 2-year warranty and maintain a stock of spare parts for fast replacement.Our technical team,with extensive experience in Yaskawa servo systems,is available 24/7 to assist with any issues,ensuring your CACR-SR30BZ1SS operates at peak performance.

Contact us today to learn how the CACR-SR30BZ1SS can enhance your heavy-duty automation systems,improve efficiency,and reduce downtime.Our experts will work with you to create a customized solution tailored to your specific application needs.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: