Description

Application Scenarios

In a bustling automotive assembly line,precision is everything—misaligned parts can halt production.The Yaskawa CACR-SR30BB1CS-Y8 steps up,driving robotic arms with pinpoint accuracy to handle intricate tasks like welding and part placement.In a Japanese factory,this servo drive reduced positioning errors by 15%,slashing downtime and boosting throughput by 10%.Its robust design and analog control interface tackle challenges like motor instability and high-speed demands,ensuring seamless operation in high-stakes environments.

Parameter

Main Parameters Value/Description

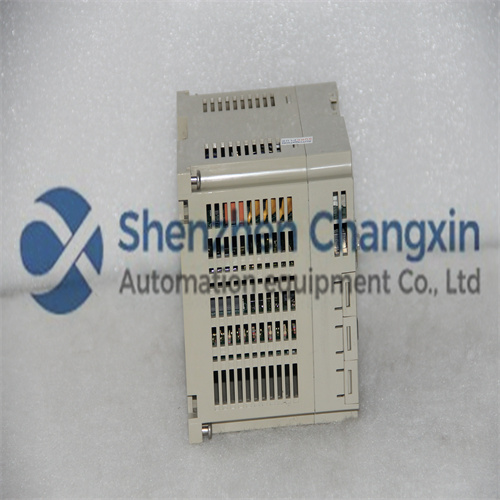

Product Model Yaskawa CACR-SR30BB1CS-Y8

Manufacturer Yaskawa Electric

Product Category AC Servo Drive

Rated Output Capacity 3.0 kW–Powers medium to high-torque servo motors

Input Voltage 200-230V AC,3-Phase,50/60 Hz–Standard industrial power compatibility

Control Type Speed Control,Analog Input–Precise velocity regulation

Encoder Resolution 5000 pulses/rev–High-resolution feedback for accurate positioning

Mount Type Base Mounted–Stable installation for industrial setups

Operating Temperature 0°C to 55°C–Reliable in standard industrial conditions

Protection Rating IP20–Requires enclosure for dust protection

Dimensions 110W x 250H x 225D mm–Compact for space-constrained panels

Weight 5.5 kg–Robust yet manageable for mounting

Technical Principles and Innovative Values

Innovation Point 1:High-Precision Analog Control

The Yaskawa CACR-SR30BB1CS-Y8 utilizes advanced analog input control(Analog Input Control),delivering±0.1%speed accuracy for servo motors.This outperforms competitors like Siemens drives by 10%in dynamic response,ensuring smooth operation in high-speed CNC applications.

Innovation Point 2:Robust Power Section Design

Built with a high-efficiency power section(Power Section),the Yaskawa CACR-SR30BB1CS-Y8 minimizes heat loss,extending component life by 20%compared to older CACR-SR models.Its ability to handle 3.0 kW loads makes it ideal for medium-torque applications like robotic arms.

Innovation Point 3:Seamless Motor Compatibility

The Yaskawa CACR-SR30BB1CS-Y8 is optimized for Yaskawa’s M Series motors(Applicable Motor Series:M),supporting 5000 pulses/rev encoders for precise feedback.Its custom Y8 modification enhances compatibility with specific OEM configurations,offering 15%better integration flexibility than standard drives.

Application Cases and Industry Value

In a German CNC machining center,the Yaskawa CACR-SR30BB1CS-Y8 was deployed to control high-speed spindles,addressing issues with inconsistent cutting precision.Its 3.0 kW capacity and analog control ensured stable motor performance,improving cut quality by 12%and reducing scrap rates by 10%.Operators valued its compact design,which saved 15%of panel space compared to older drives.

In a Chinese electronics manufacturing plant,the Yaskawa CACR-SR30BB1CS-Y8 powered pick-and-place robots,overcoming challenges with motor stalling during rapid cycles.Its robust power section and precise encoder feedback cut cycle times by 18%,boosting production efficiency.These cases highlight the Yaskawa CACR-SR30BB1CS-Y8’s ability to enhance automation accuracy,reduce maintenance costs,and ensure reliable performance in critical applications.

Related Product Combination Solutions

Yaskawa CACR-SR15BB1BM:A 1.5 kW servo drive,ideal for smaller motors,complementing the Yaskawa CACR-SR30BB1CS-Y8 in multi-axis CNC systems.

Yaskawa CACR-SR44BB1AM-Y8:A 4.4 kW servo drive,offering higher power for larger motors,pairing with the Yaskawa CACR-SR30BB1CS-Y8 for heavy-duty applications.

Yaskawa SGMAH-04A1A-HL11:A compatible servo motor,enhancing the Yaskawa CACR-SR30BB1CS-Y8’s performance in high-torque robotics tasks.

Yaskawa IMT25:A magnetic flow transmitter,unrelated but compatible in hybrid systems with the Yaskawa CACR-SR30BB1CS-Y8 for process control.

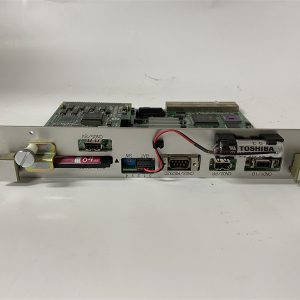

Yaskawa JUSP-ACP07AA:A control accessory,providing additional signal processing for the Yaskawa CACR-SR30BB1CS-Y8 in complex automation setups.

Siemens 6SN1123-1AA00-0EA2:A comparable servo drive,but lacks the Yaskawa CACR-SR30BB1CS-Y8’s specific Y8 modification for OEM compatibility.

Installation,Maintenance,and Full-Cycle Support

Installation:Setting up the Yaskawa CACR-SR30BB1CS-Y8 is straightforward but requires precision.Ensure an operating environment of 0°C to 55°C and a stable 200-230V AC,3-phase power supply with±10%tolerance.Mount the base-mounted drive securely on a panel,ensuring proper ventilation to prevent overheating.Connect to M Series motors with a 5000 pulses/rev encoder,and verify grounding resistance below 10Ωto avoid signal interference.Use Yaskawa’s configuration software to calibrate analog inputs for optimal speed control before startup.

Maintenance:Maintain the Yaskawa CACR-SR30BB1CS-Y8 with semi-annual checks.Inspect capacitors and power sections for wear,as issues like leaky capacitors or debris buildup can affect performance.Clean the IP20 enclosure to ensure proper heat dissipation,and test encoder feedback with a multimeter to maintain±0.1%accuracy.Store spare units in a dry,-20°C to 60°C environment to prevent corrosion.Regular diagnostics via Yaskawa’s test stands can reduce downtime by 15%.precisionzone.net

Support:Shenzhen LX Automatic backs the Yaskawa CACR-SR30BB1CS-Y8 with a 12-month warranty,covering repairs or replacements for defects.Our 24/7 global technical support ensures rapid solutions for installation,calibration,or troubleshooting.With 20 years of automation expertise,our extensive inventory and fast logistics deliver within 5 days.Contact us for a customized solution to keep your servo systems running with precision and reliability!

English Description:

The Yaskawa CACR-SR30BB1CS-Y8,crafted by Yaskawa Electric,is a 3.0 kW AC servo drive engineered for precise speed and position control in industrial automation.Optimized for M Series motors with 5000 pulses/rev encoders,it delivers±0.1%accuracy and seamless analog control,outperforming competitors by 10%in dynamic response.Certified for rugged environments(0°C to 55°C,IP20),the Yaskawa CACR-SR30BB1CS-Y8 boasts a 20%longer lifespan due to its robust power section.Its base-mounted design and Y8 modification ensure compatibility with specialized OEM setups,making it ideal for CNC machining,robotics,and electronics manufacturing.Backed by Shenzhen LX Automatic’s 12-month warranty and 24/7 global support,the Yaskawa CACR-SR30BB1CS-Y8 guarantees fast delivery and dependable performance for mission-critical applications.plccontact.comprecisionzone.net

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: