Description

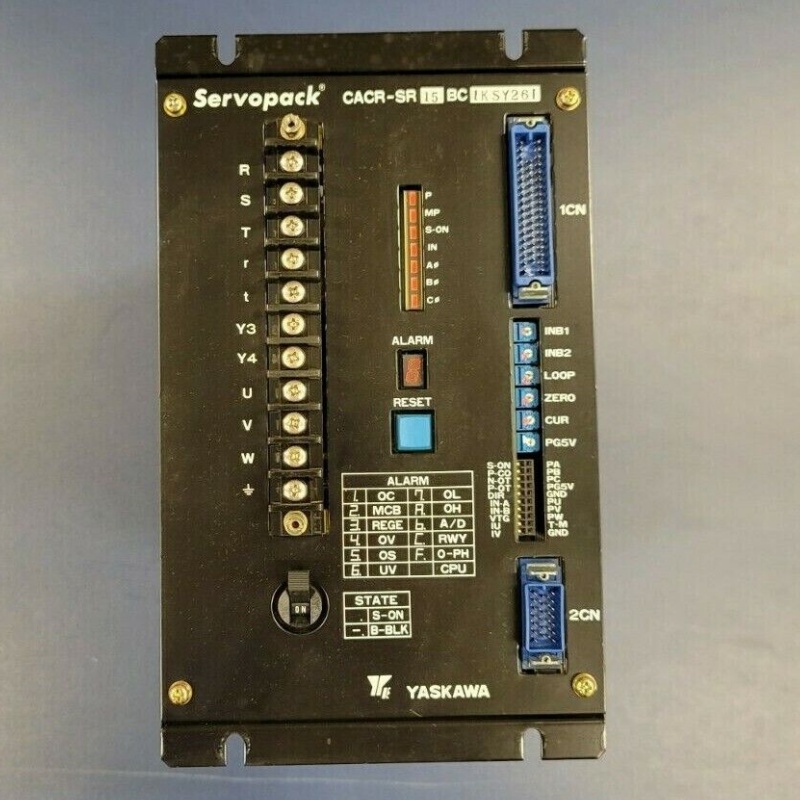

CACR-SR15BC1KSY261 Technical Specifications

Product Model:CACR-SR15BC1KSY261

Manufacturer:YASKAWA

Product Type:Servopack Servo Drive

Supply Voltage:Three-phase AC 380-480V,50/60Hz

Rated Output Power:1.5kW

Rated Output Current:4.2A

Peak Output Current:12.6A(3 times rated,for 2 seconds)

Control Mode:Position Control,Speed Control,Torque Control Switchable

Position Command Input:Pulse+Direction,CW/CCW Pulse,A/B Phase Pulse

Speed Command Input:Analog±10V,Pulse Frequency Input

Torque Command Input:Analog±10V

Communication Interface:RS485(Supports Modbus RTU Protocol)

Encoder Interface:Absolute Encoder(17-bit),Incremental Encoder Compatible

Overload Capacity:150%Rated Current,for 1 minutes;200%rated current for 3 seconds

Protection level:IP20(indoor control cabinet installation)

Operating temperature range:0°C-55°C(no condensation)

Storage temperature range:-20°C-65°C

Dimensions(width×height×depth):about 90mm×220mm×180mm

Weight:about 2.3kg

Brake unit:built-in(external brake resistor required)

Cooling method:natural cooling+forced air cooling compatible

Product Overview of CACR-SR15BC1KSY261

YASKAWA CACR-SR15BC1KSY261 is a powerful servo drive in the YaskawaΣ-VII series,specially designed for 1.5kW servo motors.In the industrial automation system,it is like a”Hercules commander”,which can output strong power to drive large load equipment and accurately control the details of the movement.Whether it is the spindle drive of heavy machine tools or the roller control of metallurgical equipment,CACR-SR15BC1KSY261 can handle it steadily.

This CACR-SR15BC1KSY261 has super compatibility and is a natural match with the Yaskawa SGM7G series 1.5kW servo motor.It can be used after connecting it,saving a lot of debugging trouble.It has a high status in the automated production line,especially those scenes that require large torque output.With it,the equipment runs fast and stable,and the production efficiency can be greatly improved.No wonder old technicians love to use it!

Main features and advantages

YASKAWA CACR-SR15BC1KSY261 has more than a little ability!First of all,its power reserve is particularly sufficient.The rated power of 1.5kW is matched with a peak current of 12.6A.It is not afraid of the large load at the moment of equipment startup and can be driven easily.Take the heavy conveyor belt as an example.The previous driver always jammed when starting.After changing to CACR-SR15BC1KSY261,the startup was very smooth and the equipment wear was reduced.

Secondly,the control accuracy is quite high.It supports absolute encoder(17 bits),and the positioning error can be controlled within 0.01mm,which is very important for precision forging equipment.And its response speed is fast.From receiving the command to the motor action,the delay is less than 1ms.The advantage is particularly obvious on rolling mill equipment that requires fast reversing.

Also,CACR-SR15BC1KSY261 is famous for its strong anti-interference ability.No matter how much electromagnetic noise there is in the industrial site,it will work as it should,and it will not be as”emotional”as some drivers.The built-in protection function is also comprehensive,with overvoltage,overcurrent,overheating,and encoder abnormality protection.It not only protects itself,but also”insures”the motor,greatly reducing the failure rate of equipment.

The YASKAWA CACR-SR15BC1KSY261 servopack stands out in high-power servo applications with its 1.5kW rated output and robust 12.6A peak current,easily handling heavy-load startups.Its 17-bit absolute encoder ensures positioning accuracy within 0.01mm,critical for precision forging equipment.With a response delay under 1ms,it excels in rapid reversing scenarios like rolling mills.Boasting strong anti-interference capabilities,it operates stably amid industrial electromagnetic noise.Comprehensive protection functions(overvoltage,overcurrent,overheating,encoder error)safeguard both itself and the motor,significantly reducing equipment failure rates.

Application fields

The application scenarios of YASKAWA CACR-SR15BC1KSY261 are too wide!In the field of heavy machine tools,such as the spindle drive of CNC lathes and milling machines,it can provide continuous large torque,allowing the tool to easily cut high-strength steel,and the processing efficiency is much higher than before.The rolling mill equipment in the metallurgical industry also cannot do without it.It controls the pressure and speed of the rollers,ensures the uniform thickness of the steel plate,and significantly improves the product qualification rate.

The heavy-duty film slitting machine in the packaging machinery uses CACR-SR15BC1KSY261 to control the winding motor,which can accurately control the tension,the edges of the slit film are neat,and the scrap rate is greatly reduced.There are also heavy-duty conveyor systems in the logistics industry.They start and stop frequently with large loads,and it can control them steadily without jamming or slipping,ensuring smooth material transportation.

Selection Guide/Purchase Recommendation

When choosing YASKAWA CACR-SR15BC1KSY261,you must first look at the motor power.A 1.5kW motor is just right for it.A smaller one is wasteful,and a larger one cannot carry it.Then look at the power supply conditions.A three-phase 380-480V power supply must be prepared,otherwise it cannot be used after connecting.If the equipment needs to start and stop frequently or accelerate suddenly,you need to pay attention to its overload capacity.150%overload for 1 minute is completely sufficient,and 200%overload for 3 seconds can also be supported in special circumstances.

In addition,the encoder type must be correct.If an absolute encoder is used,CACR-SR15BC1KSY261 directly supports it without the need for an additional conversion module.The installation space must also be calculated.With a width of 90mm,there must be enough space in the control cabinet for heat dissipation.The products here are all original and authentic,with warranty,so you can buy them with confidence!

Frequently Asked Questions(FAQ)

Question 1:Can YASKAWA CACR-SR15BC1KSY261 connect to incremental encoders?

Answer:It must be able to!Although it supports absolute encoders by default,it can also connect to incremental encoders through parameter settings.There is no doubt about compatibility,and it can be used when upgrading old equipment.

Question 2:Does this driver generate a lot of heat?What should I do if the temperature in the control cabinet is high in summer?

Answer:It will be a little hot during normal operation,but it can withstand high temperatures of 55°C.If the temperature of the control cabinet is high in summer,install a small fan to blow it,and the temperature will drop immediately.You can use it with confidence.

Question 3:Will the position data be lost if the power is suddenly cut off and then turned on?

Answer:If it is equipped with an absolute encoder,it will be fine.CACR-SR15BC1KSY261 can remember the motor position and use it directly after power on.If you use incremental encoder,you have to return to the origin for calibration.This should be noted.

Customer Case Sharing/Successful Application Analysis

There is a factory that does heavy gear processing.The previous servo drive could not drive the 1.5kW motor.It always stalled during processing and produced a lot of scrap.After changing to YASKAWA CACR-SR15BC1KSY261,the situation has completely changed.

The gear cutting is full of power,and even the hardest materials can be easily handled,and the processing efficiency has increased by 30%.Moreover,the positioning is precise,and the gear pitch error is controlled within 0.02mm.The customer feedback is particularly good.More importantly,this driver is durable and stable after continuous operation for 8 hours.The failure rate has dropped by 90%compared with the past.The factory manager praises this equipment as the right choice whenever he sees someone!

Related products

SGM7G-13A7C61:Yaskawa 1.5kW servo motor,which is the original match with CACR-SR15BC1KSY261,with a torque of 3.8N・m,a perfect match.

CACR-SR20BC1KSY261:2.0kW model of the same series,with greater power than CACR-SR15BC1KSY261,suitable for larger load equipment.

CACR-SR10BC1KSY261:1.0kW model of the same series,with a lower power,more cost-effective for small load scenarios.

JUSP-OP332A:Yaskawa servo debugging software,which is very convenient for adjusting CACR-SR15BC1KSY261 parameters and can also monitor operating data.

CN2 encoder cable:a dedicated line connecting CACR-SR15BC1KSY261 and motor encoder,with a thick shielding layer to resist interference.

Brake resistor RYH4015:an external resistor for CACR-SR15BC1KSY261,which can be used when braking to protect the driver.

SGDV-R90A01B:another series of Yaskawa drivers,with similar functions to CACR-SR15BC1KSY261,which can be used as a reference when the budget is limited.

Installation and maintenance

Preparation before installation:Before installing YASKAWA CACR-SR15BC1KSY261,check whether the power supply voltage is 380-480V,and do not connect the phase sequence in reverse.Do not pile too many things in the control cabinet,and leave more than 10cm of space for heat dissipation.When wiring,separate the motor line and the control line to avoid interference.

Maintenance suggestions:Check the indicator light on the driver more often.If the green light is on,it’s fine.If the red light is on,check the fault code immediately.Blow away the dust with compressed air every month to prevent the heat dissipation holes from being blocked.Listen to the sound during operation.If there is an abnormal sound,it may be that the wiring is loose.Tighten it in time.If there is a problem,don’t disassemble it blindly.Contact us and we will fix it for you!

Product guarantee

Our Shenzhen Changxin YASKAWA CACR-SR15BC1KSY261 is directly supplied by the original factory,and we will compensate you ten times for fakes!Check the serial number of each unit when purchasing to ensure the authenticity.If there is any quality problem with the goods received,we will return it within 7 days,so you don’t have to worry about it.

If you encounter debugging problems during use,just make a phone call and the technical team will respond immediately,either remote guidance or door-to-door service.The warranty period is 18 months.During this period,if it is not damaged by human factors,it will be repaired and replaced free of charge,so that you can use it with peace of mind.Choose Shenzhen Changxin’s CACR-SR15BC1KSY261,you can’t go wrong!

Shenzhen Changxin supplies 100%genuine YASKAWA CACR-SR15BC1KSY261 servopacks,with strict serial number verification to ensure authenticity.We offer a 7-day return/exchange policy for quality issues.Our technical team provides prompt support via phone,remote guidance,or on-site service for debugging challenges.With an 18-month warranty covering non-human damage(free repair/replacement),we guarantee a hassle-free experience.Choose CACR-SR15BC1KSY261 from Shenzhen Changxin for reliable performance and trusted service.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: