Description

Application Scenarios:

At a peaking power plant in California, frequent combustion instability events during startup were traced to inconsistent liquid fuel valve positioning. The legacy LVDT interface exhibited drift under thermal cycling, causing the control system to miscalculate actual valve stroke. After upgrading to the 8851-LC-MT, engineers leveraged its built-in ratiometric measurement, temperature-compensated excitation, and real-time linearization to restore sub-millimeter valve accuracy. The dual-channel architecture also enabled cross-validation between redundant LVDTs on the same valve, triggering an alert when mismatch exceeded 0.5%. Within two months, failed startups dropped by 90%, and NOx emissions during light-off remained consistently within permit limits—demonstrating how the 8851-LC-MT transforms raw sensor data into trustworthy actuator intelligence.

Main Parameters Value/Description

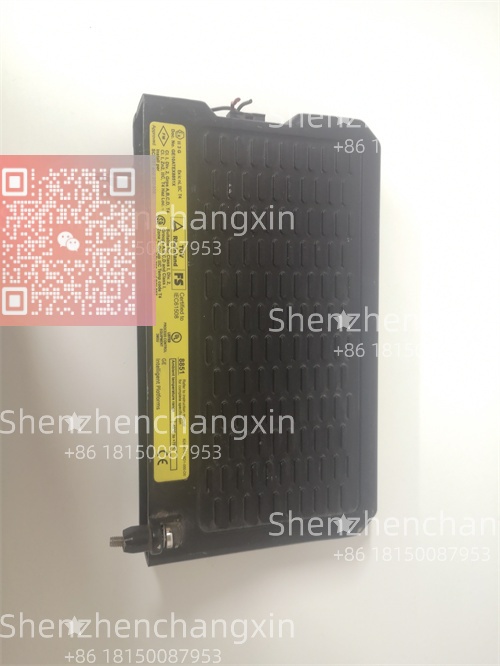

Product Model 8851-LC-MT

Manufacturer Woodward, Inc.

Product Category Dual-channel LVDT input / position feedback module

Input Type 2 × LVDT (3-wire or 4-wire differential transformer)

Excitation Voltage 3.0 V RMS nominal @ 2.5 kHz (temperature-stabilized, low-distortion sine wave)

Measurement Principle Ratiometric AC-to-DC conversion (immune to excitation voltage drift)

Output Signal Processed position value (0–100% stroke) via MicroNet backplane

Resolution 16-bit equivalent (≤0.01% of full scale)

Accuracy ±0.1% of reading (with linearization enabled)

Channel Isolation >500 V DC (channel-to-channel and channel-to-backplane)

Operating Temperature -20°C to +70°C (suitable for turbine control enclosures)

Communication Interface Dedicated high-speed serial bus (MicroNet / MicroNet Plus compatible)

Diagnostics Per-channel open/short detection, core-out-of-range, excitation fault

Technical Principles and Innovative Values:

Innovation Point 1: True Ratiometric LVDT Measurement – The 8851-LC-MT uses a precision ratiometric technique that divides the LVDT output by the excitation signal in real time, eliminating errors caused by cable resistance changes, temperature drift, or power supply fluctuations—critical for long-term valve calibration integrity.

Innovation Point 2: Onboard Linearization & Scaling – Unlike basic LVDT conditioners, the 8851-LC-MT stores custom linearization curves (via ToolKit software) to compensate for non-linearities in the mechanical linkage or core travel, delivering a true linear % stroke output directly to the turbine controller.

Innovation Point 3: Dual-Channel Redundancy with Health Monitoring – Supporting two independent LVDTs per module, the 8851-LC-MT enables 2oo2 (two-out-of-two) or 1oo2 (one-out-of-two) voting strategies for safety-critical valves, while continuously comparing channels to detect incipient sensor failure.

Innovation Point 4: Optimized for Turbine Fuel System Dynamics – With high-bandwidth signal conditioning (<10 ms response), the 8851-LC-MT captures rapid valve movements during load rejection or fast ramping—ensuring the protection system always has an accurate view of actual fuel flow authority.

Application Cases and Industry Value:

An offshore FPSO (Floating Production Storage and Offloading) vessel in the Gulf of Mexico faced unplanned blackouts due to liquid fuel valve position uncertainty during emergency generator startups. Salt-laden air had corroded LVDT wiring, causing intermittent signal loss. The platform replaced its analog conditioners with 8851-LC-MT modules, taking advantage of their sealed terminal design, robust diagnostics, and compatibility with existing LVDTs. During a subsequent fire drill, the system correctly identified a degraded LVDT 48 hours before total failure, allowing replacement during routine maintenance. Since installation, zero fuel-related trips have occurred—validating the 8851-LC-MT as a cornerstone of marine power reliability under API 670 and IEC 61511 standards.

Related Product Combination Solutions:

8851-LC-ST: Single-channel variant for non-redundant applications; shares firmware and diagnostics with 8851-LC-MT.

MicroNet Plus CPU (e.g., 5466-318): Main controller that executes fuel scheduling logic using position data from 8851-LC-MT.

8446-1019: Analog input module for pressure/temperature sensors; often used alongside 8851-LC-MT in full fuel system monitoring.

Woodward ToolKit Software: Configuration suite for uploading LVDT linearization tables and viewing real-time diagnostics of 8851-LC-MT.

5466-RACK: Standard I/O chassis supporting up to 8 modules including 8851-LC-MT, with redundant power options.

LVDT Sensors (e.g., Sensotec, Transense): Compatible 3-wire or 4-wire LVDTs; 8851-LC-MT auto-detects wiring configuration.

8200-1300: Digital input module for limit switches on the same valve assembly—complements 8851-LC-MT’s analog feedback.

Legacy 8850-series LVDT modules: The 8851-LC-MT serves as a direct, enhanced-performance upgrade with better noise immunity and diagnostics.

Installation, Maintenance, and Full-Cycle Support:

Installing the 8851-LC-MT requires mounting in a compatible MicroNet or MicroNet Plus rack and connecting LVDT leads via removable terminal blocks. No external signal conditioners or calibration pots are needed—the module auto-configures based on LVDT type selected in ToolKit. For optimal performance, use twisted-pair shielded cable with shield grounded at the cabinet only. During operation, front-panel LEDs indicate power and communication status, while ToolKit provides live position values, health alerts, and historical trend data for predictive maintenance.

As part of Woodward’s actively supported turbine control ecosystem, the 8851-LC-MT enjoys long-term availability and firmware backward compatibility. Every unit we supply undergoes functional validation: LVDT simulation across full stroke, excitation stability test, channel mismatch verification, and 72-hour thermal stress screening. Backed by a 12-month warranty and access to certified Woodward turbine control specialists, we ensure your fuel valve feedback remains accurate, secure, and compliant throughout the asset lifecycle.

Contact us for a customized solution to enhance combustion stability, meet emissions targets, and eliminate fuel-related trips—with the field-proven precision of the 8851-LC-MT.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: