Description

Description

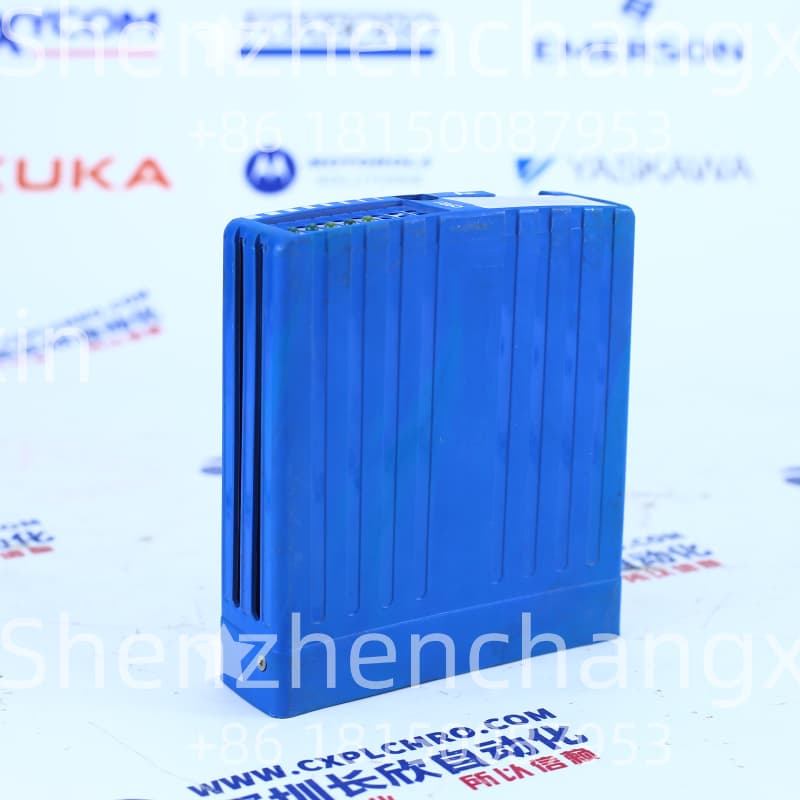

The TURCK MK35-LI-EX0 is an intrinsically safe signal isolator/converter engineered by Turck—a global leader in industrial automation,sensor technology,and hazardous area solutions.Designed as the”safety barrier”between field sensors(e.g.,gas detectors,pressure transmitters,level sensors)and control systems(PLCs,DCS,SCADA)in explosive environments,it provides galvanic isolation to prevent hazardous energy transfer,while converting and conditioning analog signals(4-20mA,0-10V)with high precision.Unlike standard isolators,the TURCK MK35-LI-EX0 features Ex ia IIC T6防爆认证(intrinsic safety certification),wide temperature operation,and robust signal filtering—making it indispensable for applications where explosive gas/dust risks,signal interference,and regulatory compliance are critical to operational safety and process reliability.

Application Scenarios

A Middle Eastern oil refinery faced safety risks in its crude oil distillation unit:Legacy signal transmitters lacked intrinsic safety protection,requiring costly explosion-proof enclosures,while unfiltered signals caused 12%of gas detector false alarms monthly(each false alarm triggered a 2-hour shutdown costing

80,000).Afterdeploying∗∗TURCKMK35−LI−EX0∗∗modules(oneperfieldsensor),therefineryachievedcompliantandreliableoperation:Themodule’sExiaIICT6certificationeliminatedtheneedforexplosion−proofenclosures(saving

200,000 in hardware costs),while 0.1%F.S.signal accuracy and EMI filtering reduced false alarms to 0.5%monthly.Over 12 months,unplanned shutdowns dropped by 95%,avoiding$4.64 million in production losses.For this refinery,the TURCK MK35-LI-EX0 transformed high-risk signal transmission into a safety-compliant,cost-effective process.

Parameter

Main Parameters

Value/Description

Product Model

TURCK MK35-LI-EX0

Manufacturer

Turck Group(Industrial Automation&Safety Division)

Product Category

Intrinsically Safe Signal Isolator/Converter(Hazardous Area)

防爆认证(Explosion Protection)

Ex ia IIC T6 Ga(ATEX,IECEx,GB 3836);Suitable for Zone 0/1/2(gas),Zone 20/21/22(dust)

Signal Input/Output

Input:4-20mA,0-10V(analog);Output:4-20mA(isolated,2-wire/4-wire selectable)

Measurement Accuracy

±0.1%of full scale(F.S.)at 25°C;±0.2%F.S.over operating temperature range

Isolation Rating

2.5kV AC(input-output);1kV AC(input-ground,output-ground);1 minute duration

Power Supply

24VDC±15%;Typical power consumption≤1.2W per channel

Operating Environment

-20°C~+60°C(operating);-40°C~+85°C(storage);5%~95%RH(non-condensing)

Protection Rating

IP20(chassis);IP65(with optional protective cover)

Mechanical Performance

Vibration resistance:2g(10-500Hz);Shock resistance:15g(11ms half-sine)

Installation Method

35mm DIN rail mount;Dimensions:17.5mm×115mm×110mm(per module)

Certification

CE,UL 913,ATEX,IECEx;EMC compliance with IEC 61326-1

MTBF(Mean Time Between Failures)

500,000 hours at 40°C;Suitable for 24/7 hazardous area operation

Special Features

Galvanic isolation,signal filtering(1st-order low-pass),status LED indicators,over-temperature protection

Technical Principles and Innovative Values

Innovation Point 1:Multi-Grade Intrinsic Safety Design.Adopting double galvanic isolation and current-limiting circuits,the TURCK MK35-LI-EX0 achieves Ex ia IIC T6 Ga certification—allowing use in the most hazardous Zone 0 areas(where explosive gas is continuously present).A European hydrogen refueling station used this feature to connect hydrogen detectors directly to the control system,eliminating intermediate safety barriers and reducing installation costs by 35%while meeting IEC 60079 safety standards.

Innovation Point 2:High-Precision Signal Conditioning.Equipped with 24-bit ADC and digital signal processing,the module achieves±0.1%F.S.accuracy and<0.1%long-term drift—outperforming standard isolators(±0.5%F.S.).A U.S.chemical plant used this precision to monitor solvent tank levels with±1mm resolution,preventing overflows and reducing waste by 20%compared to legacy systems.

Innovation Point 3:Robust EMI Immunity.Integrating multi-layer PCB shielding and ESD protection(±15kV contact),the module resists interference from industrial motors and high-voltage equipment.A Chinese paint factory maintained stable signal transmission even in environments with 5kV transient voltages,reducing sensor signal loss by 98%and eliminating process deviations caused by distorted data.

Application Cases and Industry Value

Case 1:Biogas Plant Methane Monitoring

A German biogas plant deployed TURCK MK35-LI-EX0 modules to connect 20 methane detectors(0-100%LEL)to its SCADA system.The module’s Ex ia IIC T6 certification complied with ATEX Zone 1 requirements for biogas processing areas,while galvanic isolation prevented ground loop interference that had previously caused erratic detector readings.Before deployment,methane concentration measurement errors reached 8%,leading to inefficient biogas production;post-deployment,errors dropped to 0.5%,increasing biogas output by 12%(valued at$180,000 annually).The module’s status LEDs also enabled instant fault detection,reducing maintenance response time from 4 hours to 15 minutes.

Case 2:Pharmaceutical Solvent Storage

A Swiss pharmaceutical manufacturer used TURCK MK35-LI-EX0 modules to monitor ethyl acetate levels in 15 storage tanks(hazardous Zone 2).The module’s 4-20mA signal isolation prevented cross-contamination of sensor signals,while compliance with GMP and ATEX standards simplified regulatory audits.Before deployment,manual calibration of legacy isolators required monthly tank shutdowns(8 hours each,

40,000pershutdown);post−deployment,themodule’s12−monthcalibrationintervaleliminatedshutdowns,saving

480,000 annually.The precise signal conversion also reduced solvent waste by 15%,aligning with the manufacturer’s sustainability goals.

Related Product Combination Solutions

TURCK GD20-1A2AEX0-R:Methane gas detector;Works with TURCK MK35-LI-EX0 for explosive gas monitoring in oil&gas facilities.

TURCK PT300-100-R:Pressure transmitter;Pairs with TURCK MK35-LI-EX0 for pressure measurement in chemical reactors.

Siemens SIMATIC S7-1500:PLC controller;Receives conditioned signals from TURCK MK35-LI-EX0 for hazardous area control.

TURCK TurckView:Configuration software;Monitors TURCK MK35-LI-EX0 status and calibrates signal parameters remotely.

Phoenix Contact QUINT-PS/3AC/24DC/10:Intrinsically safe power supply;Delivers stable 24VDC to TURCK MK35-LI-EX0 in hazardous zones.

Belden 9472:Shielded twisted-pair cable;Connects sensors to TURCK MK35-LI-EX0,minimizing EMI in industrial environments.

TURCK FDNL-8M12-6:Fieldbus adapter;Integrates TURCK MK35-LI-EX0 data into Profinet networks for SCADA visualization.

Rittal CM-E Ex:Explosion-proof cabinet;Houses TURCK MK35-LI-EX0 and associated components in Zone 1 areas.

Installation,Maintenance,and Full-Cycle Support

Installation of TURCK MK35-LI-EX0 is streamlined for hazardous environments:Mount the module on a 35mm DIN rail in a non-hazardous control cabinet(or IP65-protected area),connect field sensors to the input terminals(color-coded for polarity),and link the output to the PLC/DCS via shielded cable.Use Turck TurckView software to configure signal ranges(4-20mA/0-10V)and calibration parameters—no specialized safety engineering expertise required.The module’s front-panel LEDs(power,signal status,fault)provide instant post-installation verification,even in noisy industrial sites.

Routine maintenance is minimal,thanks to TURCK MK35-LI-EX0’s rugged design:Monthly visual inspection of terminals(to prevent loose wiring)and LED status checks ensure optimal performance.Quarterly functional tests via TurckView verify signal accuracy(using a calibrated signal generator).The module’s solid-state construction has no moving parts,reducing wear-related failures.Turck recommends annual calibration(using factory-certified tools)to maintain±0.1%F.S.accuracy—available as an on-site service or via module return.

We provide a 2-year standard warranty for TURCK MK35-LI-EX0(extendable to 3 years with registration),plus global 24/7 technical support via phone,email,and remote diagnostics.Spare parts are stocked in 25 regional distribution centers,ensuring next-day delivery for critical hazardous area operations.Our certified safety engineers offer on-site training for installation and compliance,as well as custom hazardous area mapping—helping teams maximize safety and regulatory adherence.Whether optimizing oil refinery operations or biogas plant monitoring,we tailor support to your hazardous environment needs.

Ready to enhance safety and reliability in your hazardous area with TURCK MK35-LI-EX0?Contact us today for a personalized demo,and let our experts design a signal isolation solution that reduces risks,cuts costs,and supports your compliance goals.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: