Description

Application Scenarios:

In a large ethylene cracking furnace complex, maintaining precise temperature and pressure within a narrow window is critical. A runaway reaction can lead to catastrophic equipment failure. The facility’s Furnace Safety Shutdown System (FSSS) is managed by a Tricon v9 controller, with the TRICONEX 9907-162 as its main processor. The module continuously monitors inputs from dozens of temperature, pressure, and flow transmitters. It executes complex safety logic at high speed, determining if conditions remain safe. Should a critical high-temperature excursion be detected, the TRICONEX 9907-162 must execute the shutdown sequence with absolute certainty—activating isolation valves, cutting fuel supply, and initiating emergency purges—all within milliseconds. The TMR design ensures that even if a random hardware fault occurs within the processor’s own circuits, the two remaining healthy channels “outvote” the faulty one, preventing a nuisance trip and guaranteeing the safety function is performed, thereby preventing a potential major process safety event.

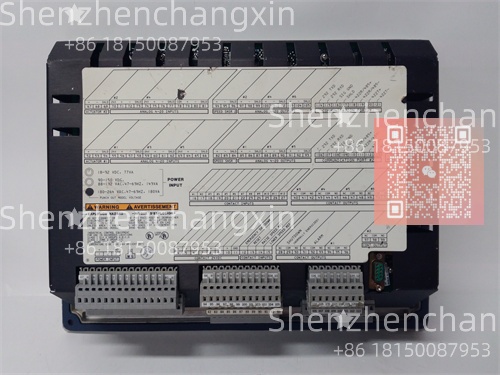

Parameter:

Technical Principles and Innovative Values:

Innovation Point 1: TMR Architecture for Fault Masking and Continuous Operation. The core innovation of the system the TRICONEX 9907-162 belongs to is its hardware-based Triple Modular Redundancy. Three separate, identical processor channels (A, B, C) within the system execute the same logic in perfect lockstep. A dedicated hardware voter compares the outputs of all three channels thousands of times per second. The TRICONEX 9907-162 plays a key role in this, as it contains a primary channel’s logic. If one channel disagrees due to a fault, it is instantly masked by the two agreeing channels. This allows the system to continue operating correctly without interruption, providing unparalleled availability and safety, which is essential for processes where a false trip can be as costly as a failure.

Innovation Point 2: Comprehensive Self-Diagnostics and Fault Tolerance. The TRICONEX 9907-162. in conjunction with the other system components, performs extensive, continuous online diagnostics. It checks its own processor health, memory integrity, and communication paths. The TMR design provides physical fault tolerance, while the diagnostics provide logical fault identification. This allows the system to not only survive a fault (fault tolerance) but also to clearly report the exact nature and location of the fault, enabling rapid, targeted maintenance. This predictive diagnostic capability is crucial for maintaining a high Safety Integrity Level (SIL) and minimizing system downtime.

Innovation Point 3: Seamless Integration and Deterministic Performance. The TRICONEX 9907-162 is engineered for deterministic, real-time performance. Its operation is not based on a general-purpose operating system but on a real-time executive that guarantees predictable scan times. This determinism is vital for safety applications where response time is a critical part of the safety function. Furthermore, it integrates seamlessly with the broader Tricon I/O and communication network, allowing engineers to design complex safety functions across a distributed system using a single, unified engineering tool (TriStation 1131), simplifying configuration and validation.

Application Cases and Industry Value:

Case Study: Offshore Platform Subsea Emergency Shutdown (ESD)

An offshore deep-water production platform uses a Tricon v9 system as its primary ESD. The TRICONEX 9907-162 main processor continuously monitors wellhead pressures, flowline temperatures, and gas detection signals from across the platform. During a severe storm, a communication glitch caused a single channel in the main processor rack to temporarily fault. The TMR architecture immediately masked this fault, and the ESD system remained fully operational, relying on the two healthy channels. Diagnostics pinpointed the fault to a specific processor channel. Because of the system’s hot-swap capability, technicians were able to safely replace the affected module, which housed the 9907-162 processor, during the next calm weather window, without ever taking the safety system offline. This event prevented a full production shutdown, which would have cost over $1 million per day in lost revenue, and more importantly, maintained critical safety protection throughout the fault and repair.

Related Product Combination Solutions:

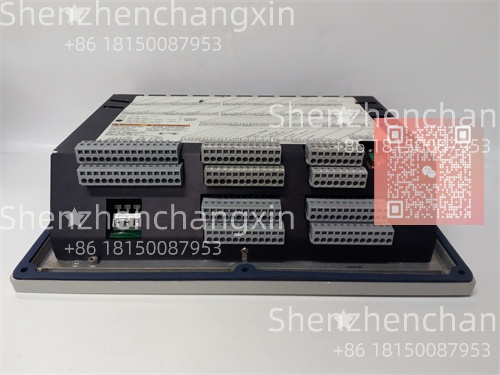

The TRICONEX 9907-162 is the central processing unit within a complete TMR rack. A functional safety controller requires:

TRICONEX Main Chassis (e.g., Model 4119): The physical enclosure and backplane that houses the three main processor modules, power supplies, and communication cards.

TRICONEX Power Supply Modules (e.g., 8319P, 8319Q): Redundant, fault-tolerant power supplies that provide clean, regulated power to all modules in the chassis, including the sensitive 9907-162 processors.

TRICONEX Communication Modules (e.g., 4351B, 4352A): These modules enable communication between the main processor and external systems, such as the Distributed Control System (DCS), engineering workstation, or other Tricon racks.

TRICONEX I/O Modules (8300 Series): A wide range of Digital Input (8312), Digital Output (8311), and Analog Input (8301) modules that interface directly with field sensors and final elements. The 9907-162 processor reads from and writes to these modules.

TRICONEX TRISTATION 1131 Software: The engineering, configuration, and diagnostic software used to program the application logic that runs on the 9907-162. and to monitor the health of the entire Tricon system.

TRICONEX Termination Panels (e.g., 9561-810): Provide the interface between the field wiring and the Tricon I/O modules, offering isolation and simplified maintenance.

Installation, Maintenance, and Full-Cycle Support:

Installation and replacement of the TRICONEX 9907-162 must be performed by qualified technicians following strict Triconex procedures. The module is designed for hot-swap replacement. The process involves using TriStation software to place the specific processor slot in a “maintenance” or “offline” mode, which gracefully removes that channel from the TMR voting logic. The faulty module can then be safely extracted, and a new TRICONEX 9907-162 inserted. Upon insertion, the system automatically synchronizes the new processor, downloads the firmware and application from the other healthy channels, and reintegrates it into the TMR set—all without interrupting the operational safety functions.

Routine maintenance is predominantly system monitoring via TriStation diagnostics. The software provides detailed health reports on the TRICONEX 9907-162 and all other modules. Physical maintenance involves ensuring clean power, proper cooling, and periodic inspection of connections. The proactive strategy is to maintain a tested spare module on-site and replace any unit that shows signs of degradation as indicated by the diagnostic system.

We provide comprehensive lifecycle support for Triconex safety systems. We supply guaranteed, fully tested TRICONEX 9907-162 main processor modules. Each unit undergoes rigorous functional testing prior to shipment. Our technical support can assist with compatibility verification, configuration questions, and integration planning. We understand the critical nature of safety system components and are committed to providing the reliable parts and expertise needed to maintain your system’s integrity and certification.

Contact us for genuine TRICONEX 9907-162 processors and expert support to ensure the continuous, fault-tolerant operation of your critical safety shutdown system.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: