Description

Application Scenarios:

In a large petrochemical refinery, the critical process of catalytic cracking is protected by a Tricon V9 Safety Instrumented System (SIS). The system’s central processing logic, housed in the TRICONEX 9300 Main Processor, continuously monitors for dangerous conditions. When a high-pressure signal is detected from a field transmitter, it is read into the system via specialized input modules like the TRICONEX 9802. The 9300 executes the safety logic, and if a shutdown is required, the command is communicated at high speed to remote subsystems via the TRICONEX 9832 communication module. The failure of any single channel in this TMR system—whether in the 9300. 9832. or 9802—is masked by the other two, allowing the safety function to be performed without interruption. This seamless integration of processing, communication, and I/O is what prevents a single point of failure from causing a catastrophic incident, protecting both personnel and assets worth hundreds of millions of dollars.

Parameter:

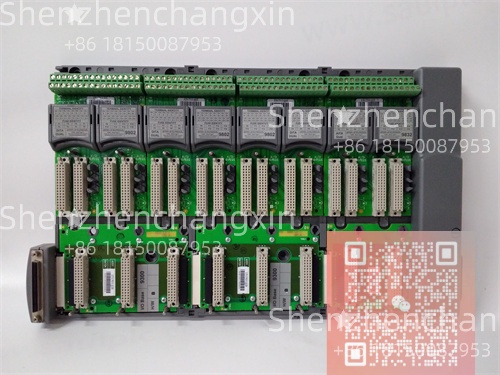

1. TRICONEX 9300 (Typical Main Processor Module)

2. TRICONEX 9832 (Typical Communication Module)

3. TRICONEX 9802 (Typical I/O Module)

Technical Principles and Innovative Values:

Innovation Point 1: Coordinated TMR Architecture Across All Layers. The true innovation lies not just in a single module, but in how the TRICONEX 9300. 9832. and 9802 work in concert to implement TMR at every system level. The 9300 processor performs three-way logic solving, the 9832 manages triple-redundant communications, and the 9802 I/O module provides triple voting at the point of signal entry/exit. This end-to-end redundancy ensures a fault in any single component—processor, network, or I/O channel—is instantly identified and masked, maintaining the system’s Safety Integrity Level (SIL 3) without interruption.

Innovation Point 2: Dedicated Functionality for Deterministic Safety. Unlike general-purpose PLCs, each module is purpose-built for safety. The TRICONEX 9300 processor uses specialized hardware and firmware for deterministic, fail-safe execution. The TRICONEX 9832 communication module employs robust, time-synchronized protocols to prevent data corruption. The TRICONEX 9802 I/O module includes circuitry for continuous on-line diagnostics, such as loop monitoring and cross-channel comparison. This dedicated design eliminates the uncertainty of general computing and guarantees a predictable response to process demands.

Innovation Point 3: Seamless Integration for Simplified Engineering & Maintenance. Despite their complexity, these modules are designed for integration. They share a common form factor, use consistent power and backplane interfaces, and are configured with unified engineering tools (like TriStation). This allows safety engineers to design a complete Safety Instrumented Function (SIF)—from sensor (9802) through logic (9300) to final element—as a cohesive system. It also simplifies maintenance: hot-swap capabilities and clear diagnostic indicators allow for swift module replacement, minimizing system downtime during repairs.

Application Cases and Industry Value:

Case Study: Offshore Gas Platform Emergency Shutdown System Modernization

An aging offshore platform was upgrading its legacy shutdown system to meet modern safety standards. The new system, centered on a Tricon V9 platform, utilized TRICONEX 9300 processors in triplets, TRICONEX 9832 modules for communication to the platform’s DCS, and racks of TRICONEX 9802 digital input modules to monitor hundreds of shutdown valves and pressure switches. During commissioning, a simulated failure of a single TRICONEX 9802 channel was injected. The system diagnostics immediately reported the fault on the specific channel, but the overall voting logic, managed by the 9300 processors, continued to process the correct state using the other two healthy channels. The platform’s safety manager confirmed the system achieved the required SIL 3 rating, and the clear diagnostics provided by these modules drastically reduced troubleshooting time, ensuring the system was operational and certified ahead of schedule, avoiding costly delays.

Related Product Combination Solutions:

A complete Tricon V9 TMR system requires a suite of integrated components:

TRICONEX 8300 Series I/O Modules: The broader family of analog and digital I/O modules (e.g., TRICONEX 8312 DI, TRICONEX 8311 DO, TRICONEX 8301 AI) that work alongside the 9802 for comprehensive field interfacing.

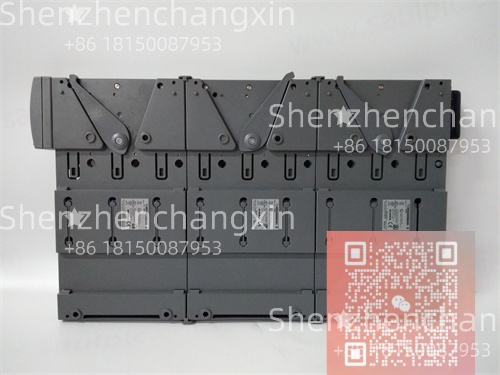

TRICONEX Main Chassis (e.g., 8110/8210): The robust, powered enclosures that house the TRICONEX 9300 processors, communication modules, and system power supplies.

TRICONEX Power Supply (e.g., 8319P): The redundant, fault-tolerant power system that provides clean, conditioned power to all modules, including the critical 9300. 9832. and 9802.

TRICONEX TRISTATION 1131 Software: The essential engineering workstation software used to program the application logic in the 9300 processors and configure all system hardware, including the 9832 and 9802 modules.

TRICONEX Communication Modules (Peer-to-Peer): Modules like the TRICONEX 4351B that work with the 9832 to enable high-speed communication between multiple Tricon racks for larger, distributed safety systems.

Installation, Maintenance, and Full-Cycle Support:

Installation of these modules must be performed by certified technicians following strict Triconex procedures and safety standards. The modules are keyed and designed to install into specific slots within the Tricon V9 chassis. Proper grounding and use of the specified Triconex backplane and power supplies are critical. Configuration is performed entirely through the TriStation 1131 software, where the hardware is declared, and the specific properties of modules like the TRICONEX 9832 (communication parameters) and TRICONEX 9802 (I/O types) are defined.

Routine maintenance is centered on the system’s extensive online diagnostics. The health of the TRICONEX 9300. 9832. and 9802 modules is continuously monitored, with faults reported to the engineering workstation. Physical maintenance primarily involves monitoring LED status indicators and ensuring a clean, cool operating environment. The hot-swap capability is critical: if a module like the 9802 is diagnosed as faulty, it can be safely de-energized and replaced without taking the entire TMR safety system offline, as the remaining two channels maintain the safety function.

We provide end-to-end support for legacy Triconex safety systems. Our services include supplying fully certified, tested, and compatible TRICONEX 9300. 9832. and 9802 modules. Each unit is rigorously tested on Triconex hardware to verify functionality. We understand the criticality of version compatibility and firmware levels in safety systems and provide detailed documentation. Our technical team can assist with compatibility verification and system integration questions, ensuring you can maintain the certified integrity and availability of your safety instrumented functions.

Contact us for certified Triconex V9 components and expert support to maintain the integrity of your critical safety shutdown systems.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)