Description

Application Scenarios:

In a high-performance semiconductor die bonding machine, ultra-precise coordination between multiple servo axes—handling X-Y table positioning, Z-axis force control, and rotary feed mechanism—is critical. Any lag or vibration results in misaligned, defective bonds. The machine utilizes a multi-axis servo drive where the RELIANCE ELECTRIC S-D4006 module acts as the central control brain. It receives high-speed trajectory commands from a host PLC, performs real-time calculations for each axis, and executes complex spline and electronic gearing profiles. The module’s advanced digital control loops, with built-in resonance suppression and feed-forward algorithms, compensate for mechanical imperfections, ensuring buttery-smooth, micron-accurate motion. This solves the core pain points of precision, speed, and synchronization in high-tech manufacturing, directly impacting yield and throughput.

Technical Principles and Innovative Values:

Innovation Point 1: Centralized Multi-Axis Control Architecture. The RELIANCE ELECTRIC S-D4006 is designed for coordinated multi-axis control within a single drive chassis. Unlike separate single-axis drives, it can manage the power stages for multiple motors from one intelligent module. This architecture allows for tightly synchronized motion between axes with minimal communication latency, as coordination happens internally on the S-D4006. enabling complex contouring, gearing, and camming essential for advanced machinery.

Innovation Point 2: Advanced Digital Signal Processing for Optimal Performance. The module leverages a high-speed, application-specific digital signal processor. This allows it to run complex control algorithms—including notch filters to dampen mechanical resonances, advanced feedforward to reduce following error, and sophisticated velocity profiling. This level of digital processing provides superior performance, stability, and tuning flexibility compared to analog or simpler digital drives, translating to higher machine speeds and better finished product quality.

Innovation Point 3: Integrated System Diagnostics and Tuning Software. The S-D4006 is designed to work intimately with proprietary configuration and tuning software (e.g., Reliance/Allen-Bradley Motion Assistant). This software provides an intuitive interface for auto-tuning control loops, diagnosing mechanical and electrical issues through built-in oscilloscope and data logging functions, and optimizing performance. This turns the module from a simple amplifier into a powerful diagnostic tool for the entire mechanical system.

Application Cases and Industry Value:

A precision metal stamping press manufacturer was facing a critical challenge: their existing servo feed system could not maintain consistent material positioning at higher speeds, leading to scrap and tool wear. The limitation was in the servo drive’s ability to handle the rapid changes in torque required during the feed-hold cycle. They upgraded the control system by implementing a new multi-axis drive centered on the RELIANCE ELECTRIC S-D4006 module. Engineers used its advanced software to implement a dual-loop control strategy (motor encoder and a secondary load encoder) and tune the aggressive feedforward parameters. The result was a 40% increase in feed speed while improving positioning accuracy by over 60%. The plant manager stated, “The S-D4006 gave us the control fidelity we needed. The scrap rate plummeted, and we could finally run at the press’s designed speed. The return on investment was measured in weeks, not months.” This demonstrates the module’s value in unlocking machine potential, reducing waste, and significantly boosting production efficiency.

Related Product Combination Solutions:

ALLEN-BRADLEY 1398-DDM-005/-020: Digital Drive Modules. The S-D4006 is the core control card that plugs into these multi-axis drive chassis, which provide the power amplification and infrastructure.

RELIANCE ELECTRIC 57C-Series Motors: High-performance brushless AC servo motors. These are the prime movers driven by the amplifiers controlled by the S-D4006. forming a optimized motion system.

ALLEN-BRADLEY 1398-PDM- series: Positioning Drive Modules. For applications requiring high-accuracy point-to-point positioning, these modules complement the S-D4006’s capabilities in velocity/torque control.

ALLEN-BRADLEY 1398-CMM-010: A SERCOS Interface Communication Module. This optional module can be added to a drive chassis to network multiple drives, including those with S-D4006 control, via a high-speed fiber-optic ring for synchronized multi-axis control.

RELIANCE ELECTRIC 0-60000 Series Encoders: High-feedback devices. The precision of the S-D4006’s control loops depends on the quality of feedback from such encoders attached to the motor and load.

ALLEN-BRADLEY 1398-PDM-040: A specific high-power positioning drive. It illustrates the family’s range, where the S-D4006 technology is applied in different power and form-factor packages.

Reliance AutoMate 40/50 Series PLCs: The programmable logic controllers that often serve as the host machine controller, sending motion commands over a bus to the drives containing the S-D4006.

Installation, Maintenance, and Full-Cycle Support:

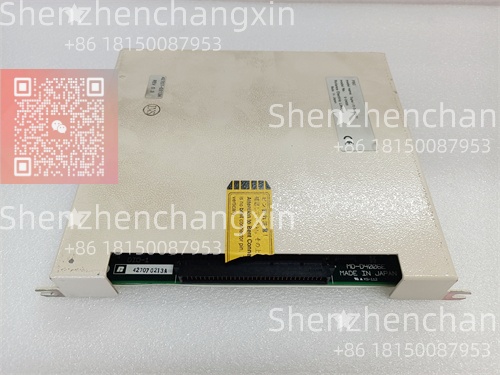

Installation of the RELIANCE ELECTRIC S-D4006 module requires strict ESD (Electrostatic Discharge) precautions and should only be performed on a powered-down drive chassis. The module is carefully inserted into its dedicated, guided slot within the 1398 drive and secured. Critical connections include mating with the internal backplane for power and data, and ensuring any associated feedback or communication daughter-cards are properly seated. The most crucial post-installation step is loading the correct firmware and application parameters via the dedicated software suite.

Maintenance is predominantly condition-based and software-driven. The module provides extensive real-time fault logging and performance data. Technicians should monitor for alarms related to overheating, communication faults, or feedback errors, which often point to external issues (motor, encoder, wiring). The module itself is a solid-state device with no user-serviceable parts. If diagnostics indicate a board-level failure, the module can be replaced. It is vital that the replacement S-D4006 has the correct firmware revision and that a full parameter backup from the failed unit is restored to the new one. We supply fully tested, compatible RELIANCE ELECTRIC S-D4006 modules. Our technical support can assist with the critical steps of configuration backup, firmware verification, and post-replacement tuning to ensure your multi-axis motion system is restored to optimal performance.

Contact us for your RELIANCE ELECTRIC S-D4006 requirements and for expert support in maintaining or upgrading your critical motion control systems.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: