Description

Description:

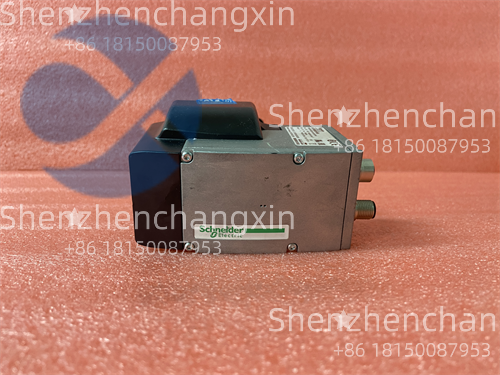

The SCHNEIDER ELECTRIC ILS1B853S1456 is a safety interlock switch from the Harmony XA range, designed to provide a high-safety solution for guarding applications on industrial machinery. It monitors the position of guards, doors, or gates, ensuring safe operation by preventing machine start-up or triggering a safe stop when the guard is open. This specific model features a solenoid-actuated guard locking mechanism and positively guided safety contacts, making it suitable for applications where unauthorized or accidental access to hazardous zones must be prevented.

Application Scenarios:

In an automated robotic welding cell, operators need periodic access for part loading and maintenance, but the robot’s movements and welding process present severe crushing, impact, and burn hazards. A safety fence with an access gate encloses the cell. The SCHNEIDER ILS1B853S1456 safety interlock switch is installed on this gate. When the gate is closed, the switch’s actuator is engaged, its safety contacts close, and the solenoid mechanically locks the gate shut. This “guard locked” signal is read by the safety controller, allowing the robot to operate in automatic mode. If an operator needs access, they must initiate a safe stop via a dedicated enable switch. Only after the robot is in a safe state will the safety controller de-energize the ILS1B853S1456’s solenoid, unlocking the gate. Opening the gate then immediately breaks the safety circuit, providing redundancy. This ensures hazardous motion cannot occur while the gate is open, protecting personnel from serious injury.

Technical Principles and Innovative Values:

The SCHNEIDER ILS1B853S1456 implements fundamental safety principles through robust electromechanical design to prevent circumvention and ensure fail-safe operation.

Innovation Point 1: Positively Guided (Force-Guided) Safety Contacts. This is a core safety feature. The contacts are mechanically linked such that if a normally closed (NC) contact welds shut in a fault condition, the physical linkage forces all associated normally open (NO) contacts to remain open, and vice-versa. This ensures the safety circuit always sees a “stop” or “guard open” signal in the event of a contact fault, maintaining the highest level of safety integrity (Category 4. PL e).

Innovation Point 2: Integrated Solenoid Guard Locking. The built-in electromagnetic lock prevents the guard from being opened while the machine is in a hazardous state. The lock is only released by a signal from the safety controller once all safe conditions are met (e.g., drives are torqued off, axes are at rest). This prevents operators from bypassing the interlock by simply forcing the door open and is crucial for machines with long stopping times or residual hazards.

Innovation Point 3: High Resistance to Defeat and Environmental Stress. The switch is designed per ISO 14119 to resist common defeat attempts like forcing with tools or using a magnet to mimic the actuator. The robust housing offers a high IP rating (e.g., IP67), protecting internal components from dust, coolants, and high-pressure washdowns, ensuring reliable long-term operation in harsh manufacturing environments.

Application Cases and Industry Value:

Case Study: Enhancing Safety on a High-Speed Packaging Line.

A food and beverage plant operated a high-speed packaging machine with an infeed area where jams occasionally occurred. The clear plastic guard had a simple interlock, but operators, under pressure to maintain line output, would sometimes bypass it with a zip-tie to clear jams quickly, exposing themselves to entanglement and laceration hazards. The plant upgraded to a SCHNEIDER ILS1B853S1456 switch on the guard.

Now, to clear a jam, the operator must press a “Guard Request” button. The safety controller verifies the machine is stopped and de-energizes the switch’s locking solenoid with a delay. An audible beep sounds, indicating the guard is now unlocked. Only then can the guard be opened, which immediately breaks the safety circuit. After closing the guard, the operator must press a “Reset” button at a safe location to restart. The plant’s EHS manager stated, “The ILS1B853S1456 eliminated the ability to bypass the guard. The locking function forces a controlled, safe procedure. We’ve had zero at-risk behaviors since installation, and while minor stoppages take slightly longer to clear, we’ve completely removed a serious injury risk. The investment paid for itself in risk reduction alone.”

Related Product Combination Solutions:

Schneider Electric XPS Series Safety Controllers: The logic solver that monitors the ILS1B853S1456’s contacts, controls its locking solenoid, and interfaces with the machine’s main PLC for safe stop functions.

Actuator (e.g., XA2A11 or similar): The separate actuator tongue that mounts on the moving guard/door and interacts with the switch head. Must be correctly paired for proper operation.

Schneider Electric Preventa XCS Coding Plugs: Unique mechanical coding keys that prevent a standard actuator from operating a coded switch, adding another layer of anti-tamper protection.

Schneider Electric Harmony XB5/B6 Safety Push Buttons: Emergency stop and enabling switches that form part of the overall safety circuit with the interlock switch.

Schneider Electric TeSys Island Motor Management System: Can receive a safe stop signal from the safety controller (triggered by the interlock) to safely disconnect motor power.

Schneider Electric Modicon M2xx / LMC078 Motion Controller: For coordinating safe motion functions with guard door status in applications like robots or CNCs.

Safety-rated Relays (e.g., XPSR Series): Can be used in conjunction with or as a simpler alternative to a safety controller to evaluate the interlock’s dual-channel signal.

Installation, Maintenance, and Full-Cycle Support:

Proper installation is critical for safety function. The switch body is mounted on the fixed machine frame, and the corresponding actuator is mounted on the moving guard, with precise alignment (gap, overlap) as per the manual. Wiring must follow safety standards: the two NC and two NO contacts are typically wired in a dual-channel, cross-monitored configuration to the safety controller. The locking solenoid is wired to a monitored safety output. A mechanical override (e.g., a small access hole for a tool) is often required for emergency release.

Maintenance involves regular inspection for physical damage, verification of secure mounting, and functional testing. The safety function should be tested periodically: close the guard, verify locking engages, attempt to start the machine, then try to open the guard—it should remain locked. Only after initiating a safe stop should the guard unlock. Our full-cycle support ensures a compliant and effective safety system. We provide detailed mounting and wiring diagrams, assist with safety performance level (PLr) calculations for your application, and supply genuine components. We are committed to helping you implement safety solutions that protect your personnel and meet international standards.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)