Description

Application Scenarios

In a large hospital’s building management system,coordinating the HVAC,lighting,and access control is critical for patient comfort,energy efficiency,and security.TheSAIA PCD7.D1XXPLC is installed as the central controller for an entire wing.It processes inputs from hundreds of temperature sensors,occupancy detectors,and door contacts.Based on its programmed logic,it commands air handling units,VAV boxes,and lighting circuits.Its integrated networking capabilities allow it to communicate seamlessly with other system controllers and a central SCADA system via protocols like Modbus,BACnet,or SAIA’s own S-Bus.A failure of this controller would disrupt the entire building’s automated operations,highlighting its role as the intelligent core of the automation system.

Parameter

Parameter

Specification

Product Model

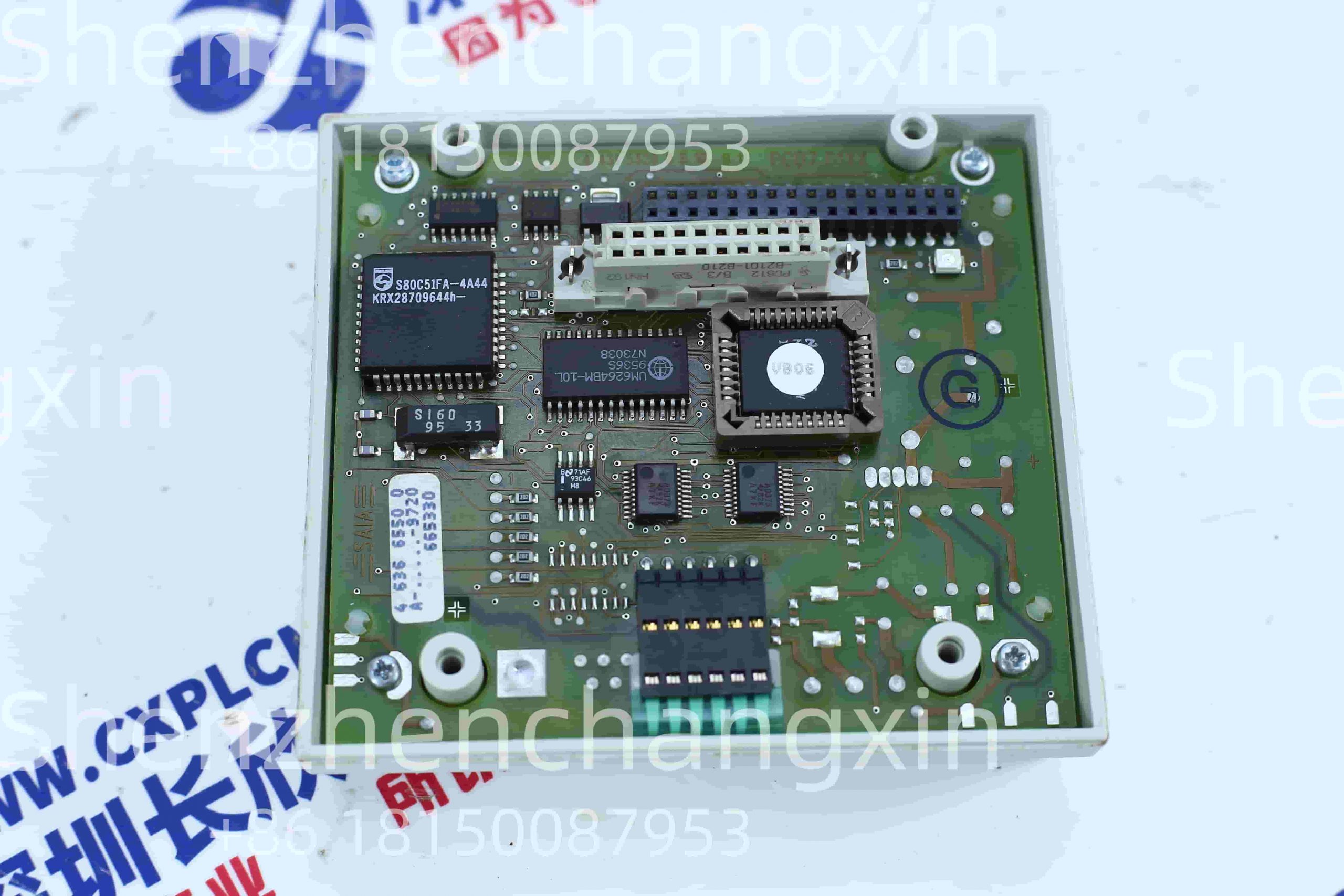

PCD7.D1XX

Manufacturer

SAIA-Burgess Controls(SAIA)

Product Line

PCD-7 Series

Product Type

High-Performance Programmable Logic Controller(PLC)

Processor

Powerful 32-bit RISC Microprocessor

Program Memory

Extensive memory for complex applications(e.g.,2 MB)

Data Memory

Large retentive data memory for variables and recipes

I/O Capacity

Supports a large number of local and remote I/O points

Communication Ports

Multiple ports;typically includes RS-232,RS-485

Supported Protocols

S-Bus(SAIA),Modbus RTU/ASCII,BACnet,others(configurable)

Real-Time Clock

Integrated battery-backed real-time clock

Programming Standard

IEC 61131-3(LD,FBD,IL,SFC,ST)

Programming Software

SAIA PG5 Control System

Technical Principles and Innovative Values

TheSAIA PCD7.D1XXis built for flexibility and power in demanding control environments.

Innovation Point 1:Multi-Protocol Communication Gateway.A key strength of thePCD7.D1XXis its native support for a wide range of industrial and building automation protocols.This allows it to act as a communication gateway,seamlessly integrating devices from different vendors(e.g.,variable frequency drives on Modbus,room controllers on BACnet)into a unified control strategy without the need for additional hardware converters.

Innovation Point 2:Powerful Processing for Complex Logic.Equipped with a high-performance 32-bit processor and substantial memory,the controller can execute complex control algorithms,extensive data logging,and sophisticated scheduling tasks.This makes it suitable for applications that go beyond simple on/off control,such as energy optimization routines and batch process management.

Innovation Point 3:Standardized Programming with IEC 61131-3.The controller is programmed using the international IEC 61131-3 standard in the SAIA PG5 software.This allows engineers to use familiar languages like Ladder Diagram(LD),Function Block Diagram(FBD),and Structured Text(ST),improving code reusability,simplifying maintenance,and reducing engineering time.

Application Cases and Industry Value

Case Study:Enhancing Energy Efficiency in a University Campus.A university sought to reduce its energy consumption across multiple buildings.The existing systems were disparate and inefficient.The project involved installingSAIA PCD7.D1XXcontrollers in each building.These PLCs now centralize control of heating,ventilation,and lighting based on real-time occupancy data and weather forecasts.They communicate with each other and a central energy management system via a BACnet/IP network.The powerful logic capabilities of thePCD7.D1XXallow for sophisticated optimization algorithms.This implementation led to a 25%reduction in energy costs campus-wide,demonstrating the controller’s ability to manage complex,networked automation tasks effectively.

Related Product Combination Solutions

TheSAIA PCD7.D1XXserves as the central processor in a comprehensive control system.

SAIA Digital/Analog I/O Modules:Expansion modules(e.g.,PCD7.A1XX series)that connect to the controller to increase its I/O point capacity.

SAIA S-Bus Communication Modules:Modules for extending the S-Bus network to remote I/O drops over long distances.

SAIA Operator Panels(e.g.,PCD5.T1XX):HMI terminals for local operator control and visualization.

SAIA PG5 Software:The essential engineering environment for programming,configuring,and debugging thePCD7.D1XXand the entire system.

Power Supply Units:Dedicated power supplies for the PLC rack and I/O modules.

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:Installing theSAIA PCD7.D1XXinvolves mounting it on a standard DIN rail within a control panel.Wiring must be done according to the manufacturer’s guidelines,with careful attention to communication cabling and grounding to ensure noise immunity.Configuration and programming are performed offline using the PG5 software and then downloaded to the controller.

Routine maintenance includes checking the status LEDs,ensuring the backup battery is functional to retain the program and real-time clock,and keeping a secure backup of the application program.The modular design facilitates easy replacement of the controller if necessary.

Our support for theSAIA PCD7.D1XXcovers its entire lifecycle.We provide genuine,reliable controllers and can assist with technical inquiries regarding integration and programming.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: