Description

Application Scenarios

At a desalination plant in Saudi Arabia, operators struggled with glare on legacy HMIs and frequent failures due to heat and humidity. The facility replaced aging terminals with ABB 6186M-17PT units mounted directly on control panels near high-pressure pumps. The anti-reflective display remained readable under direct desert sunlight, while the IP65-sealed front resisted salt-laden moisture. Running Compact HMI software connected to an AC 800M controller via Ethernet, the 6186M-17PT provided real-time monitoring of membrane pressure, flow rates, and chemical dosing—with alarm history and trend logs accessible at a tap. Over two years, zero HMI-related failures occurred, and maintenance staff reported a 40% reduction in troubleshooting time thanks to the intuitive interface and stable platform.

Parameter

表格

Technical Principles and Innovative Values

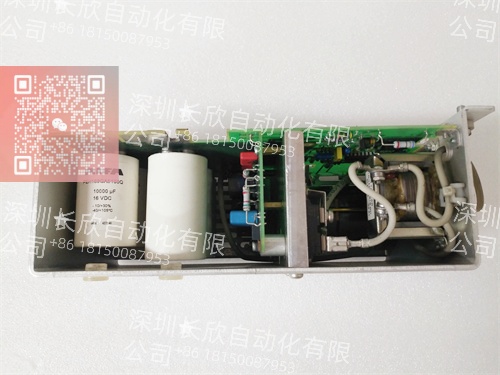

Fanless & Sealed Design: No internal fans mean no dust ingress or mechanical wear—critical for long-term reliability in dusty or corrosive plants.

Resistive Touch Technology: Unlike capacitive screens, the 6186M-17PT works with gloves, styluses, or wet fingers—ideal for field operators in PPE.

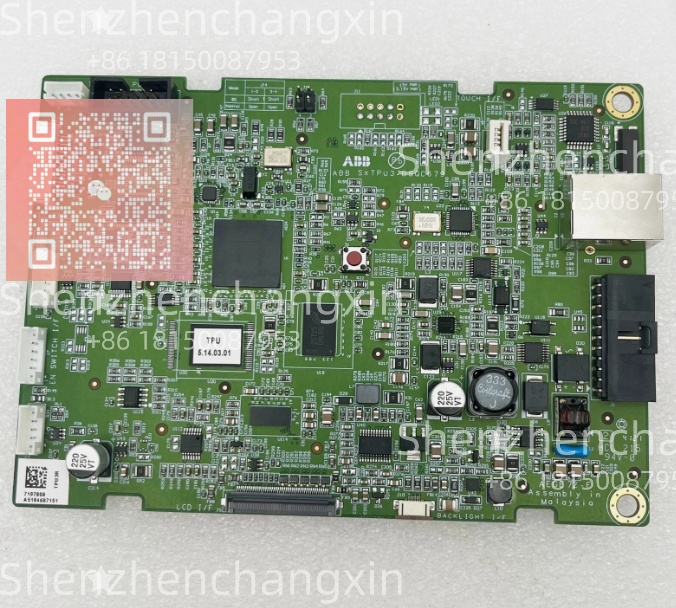

Deep ABB Ecosystem Integration: Pre-validated drivers and templates for System 800xA, Control Builder M, and Compact HMI reduce engineering time by up to 50%.

Industrial-Grade Components: Solid-state storage, wide-temp capacitors, and conformal-coated PCBs ensure >70.000 hours MTBF.

Future-Proof Connectivity: Gigabit Ethernet and USB support modern peripheral integration (e.g., barcode scanners, USB drives for backup).

Application Cases and Industry Value

In a North American ethanol refinery undergoing a DCS modernization, engineers needed to replace obsolete operator consoles without rewiring entire control rooms. They installed ABB 6186M-17PT units as local HMI stations next to distillation columns, connecting them via fiber-Ethernet to a central 800xA system. The large screen allowed split-view displays: one side showing live trends, the other for alarm management. Because the 6186M-17PT supported native OPC UA and Modbus TCP, it also integrated legacy analyzers from third-party vendors. The project was completed 3 weeks ahead of schedule, and operators praised the responsive touch interface during shift handovers. The 6186M-17PT proved that even “legacy” HMIs, when built to ABB standards, deliver decades of service.

Related Product Combination Solutions

System 800xA – Full DCS platform for enterprise-wide control and visualization.

AC 800M PM864 – Controller commonly linked to 6186M-17PT via Ethernet.

Compact HMI – Lightweight visualization software optimized for 6186M series.

Panel 800 – ABB’s newer HMI line (successor); consider for greenfield projects.

CI854A / CI626A – Communication modules enabling protocol bridging to the HMI.

TK801V015 – Shielded Ethernet cables for noise-immune data links.

TB820 – Redundant power supply for critical HMI stations.

ABB Ability™ Genix – For advanced analytics if upgrading to cloud-connected operations.

Installation, Maintenance, and Full-Cycle Support

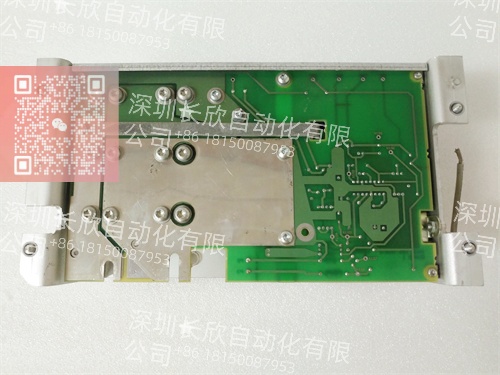

Installation of the 6186M-17PT requires a standard panel cutout (typically 439 × 344 mm), secure mounting with included brackets, and connection of 24 V DC power plus Ethernet. The unit boots into a pre-configured HMI runtime environment—no OS setup needed if deployed with ABB engineering tools.

Maintenance is minimal: clean the screen with mild detergent, ensure ventilation gaps are unobstructed (despite being fanless, rear airflow helps), and back up configuration images regularly via USB. In case of failure, the modular design allows replacement in under 15 minutes—field wiring remains untouched.

We supply tested, fully functional ABB 6186M-17PT units—both new surplus and refurbished—with verified touch calibration, display uniformity, and boot integrity. Each unit includes power/communication specs, cutout templates, and compatibility notes for 800xA versions. Our team provides firmware recovery, OS re-imaging, and migration planning to Panel 800 if desired.

Contact us to extend the life of your control system with the durable, field-proven performance of the ABB 6186M-17PT—or explore upgrade paths to next-generation visualization platforms.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: