Description

Application Scenarios:

In a large chemical processing plant, a critical reactor’s temperature, pressure, and flow must be controlled with absolute precision and reliability to ensure both product quality and process safety. A failure in the control system could lead to dangerous conditions or a costly shutdown. The ABB PCD232A 3BHE022293R0101 is deployed as part of a redundant controller setup managing this reactor. One module acts as the primary controller, executing the control logic in real-time, while its paired counterpart runs in hot standby, continuously synchronizing data. The module’s high processing power handles complex PID loops and sequence control, while its robust design ensures immunity to electrical noise. If a disturbance or fault affects the primary module, the system automatically and seamlessly switches control to the standby PCD232A within milliseconds, preventing any process disruption. This application highlights its role in safeguarding both production continuity and plant safety.

Technical Principles and Innovative Values:

Innovation Point 1: Engineered for High Availability and Seamless Failover. The ABB PCD232A is architected from the ground up for mission-critical availability. When used in a redundant pair, the modules maintain a continuous, high-speed data synchronization link. The standby module mirrors the entire state (process data, program, and operating mode) of the primary in real-time. This design enables a bumpless transfer of control (failover) in the event of a hardware fault, network issue, or controlled switchover, with zero disruption to the running process. This is a core innovation for non-stop operations.

Innovation Point 2: Deterministic Performance and Robust Execution. The module delivers predictable, real-time control performance. Its operating system and firmware are optimized for deterministic execution of control logic, ensuring that scan times and task scheduling are consistent and reliable. This is critical for fast control loops and safety-related functions where timing is as important as the logic itself. The hardware is also built to withstand the harsh electrical and environmental conditions of industrial settings.

Innovation Point 3: Deep Integration within the ABB Control Ecosystem. The PCD232A is not a standalone computer; it is a fully integrated component of the AC 800F controller family. It works seamlessly with ABB’s S800 I/O system for fast, deterministic I/O scanning and with engineering tools like Control Builder for configuration and programming. This deep integration simplifies system design, commissioning, and diagnostics, as the entire control strategy—from the controller logic in the PCD232A to the I/O point configuration—is managed within a unified engineering environment.

Application Cases and Industry Value:

Case Study: Power Plant Burner Management and Safety System. In a combined-cycle power plant, the safe start-up, monitoring, and shutdown of multiple gas turbine burners is paramount. A dedicated safety system built on redundant ABB PCD232A 3BHE022293R0101 controllers was implemented. These controllers continuously monitor flame status, fuel valve positions, and purge sequences. Their high reliability and deterministic scan times ensure that safety-critical logic (e.g., “if no flame detected, close fuel valve within 500ms”) is executed without fail. The redundant configuration provided the necessary availability, as the plant could perform maintenance on one controller while the other remained online, with no impact on safety or operation. The plant engineers valued the system’s certifiable reliability and the ease of programming complex interlock sequences, which contributed to both enhanced safety and operational flexibility, allowing for more efficient start-up cycles.

Related Product Combination Solutions:

The ABB PCD232A operates as the brain within a larger control system. A typical redundant controller setup includes:

ABB PCD232A 3BHE022293R0101: The primary controller module.

A second PCD232A module: Configured as the hot standby for redundancy.

ABB S800 I/O Baseplate & Modules (e.g., TU833. AI810. DI810): The remote or local I/O system that interfaces with field sensors and actuators, connected via a high-speed fieldbus.

ABB CI871K01 or CI854AK01: Communication interface modules (for Ethernet, PROFIBUS, etc.) that allow the PCD232A-based controller to communicate with other systems or networks.

ABB Power Supply Units (e.g., for the controller rack): Provide stable, redundant power to the control hardware.

ABB Control Builder Professional: The engineering and configuration software used to program the application logic, configure hardware, and set up the redundancy for the PCD232A controllers.

Installation, Maintenance, and Full-Cycle Support:

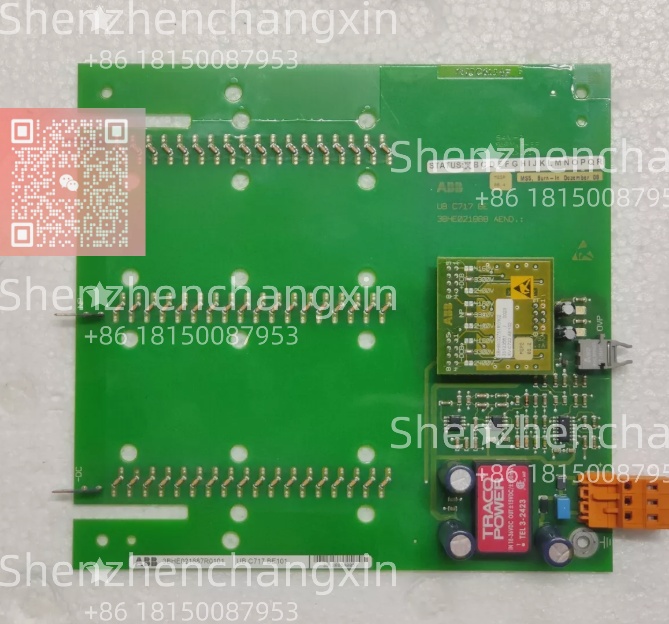

Installation & Commissioning: Installing the ABB PCD232A involves mounting it in its designated slot within an AC 800F controller rack. Critical steps include correctly setting any hardware configuration switches (like node IDs) and establishing the high-speed synchronization link between the primary and standby modules. The majority of the configuration is done in software using ABB’s Control Builder. Here, the hardware is defined, the redundancy is configured, and the application logic is developed and downloaded to the controller pair.

Maintenance & Fault Handling: The module is designed for high reliability with minimal routine maintenance. The system’s diagnostics continuously monitor the health of both controller modules. In a redundant configuration, a failed module can typically be replaced online (hot-swapped) following proper procedures. The system will automatically transfer to the healthy unit, and once the new PCD232A is inserted, it will synchronize with the active controller. For a non-redundant system, replacement requires a planned shutdown.

Full-Cycle Support: We provide comprehensive support for the ABB PCD232A 3BHE022293R0101. This includes sourcing genuine, factory-tested, or certified refurbished units. Each controller module undergoes rigorous testing to verify full functionality, including processor tests, memory checks, and communication tests. We offer technical guidance on configuration and integration into your existing system architecture. Our goal is to ensure you receive a reliable, fully compatible component backed by expert support to maintain the high availability of your critical control system.

Contact us for the genuine ABB PCD232A 3BHE022293R0101 controller module and professional technical support for your high-availability automation system needs

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: