Description

Application Scenarios:

In a critical synthesis gas compressor at a petrochemical plant, the shaft rotates at over 10.000 RPM. Even a slight increase in shaft vibration can indicate developing issues like imbalance, misalignment, or bearing wear. A standard speed monitor might not detect this until it’s too late. The EPRO PR6423/003-030 probe, installed perpendicular to the shaft, continuously measures the microscopic gap between its tip and the shaft surface. This signal, processed by its companion amplifier, provides a precise DC voltage proportional to the average gap (for position) and an AC voltage proportional to dynamic motion (for vibration). When vibration levels exceed pre-set alarms, the protection system can trigger an early warning or even a safe shutdown, allowing maintenance to be planned before a forced outage and potential damage worth millions occurs. It solves the critical pain point of unplanned downtime and catastrophic asset failure in high-value rotating equipment.

Parameter:

Technical Principles and Innovative Values:

Innovation Point 1: Non-Contact, High-Fidelity Measurement. The core innovation is the eddy current principle. The probe tip contains a coil energized by a high-frequency signal from the amplifier. This creates an electromagnetic field. When near a conductive shaft, it induces circular eddy currents in the shaft surface. The energy loss in this interaction changes the coil’s impedance, which is precisely measured. This method provides a high-resolution, non-contact measurement completely immune to oil, steam, or other contaminants in the air gap, ensuring reliability in harsh environments.

Innovation Point 2: Simultaneous Dynamic and Static Measurement. A single PR6423/003-030 probe, through its connected amplifier, delivers two key pieces of information. The AC component of its signal corresponds to the dynamic vibration (peak-to-peak displacement), crucial for detecting mechanical faults. The DC component corresponds to the average gap, indicating the shaft’s static position within the bearing (eccentricity), which is vital for detecting load changes or bearing wear. This dual-output capability makes it a versatile sensor for comprehensive machinery diagnosis.

Innovation Point 3: System Integration and Calibration Simplicity. The probe is part of a precisely calibrated system. The PR6423/003-030 is characterized with a specific “K factor” (sensitivity, e.g., 8 mV/µm) and “Linear Range”. When paired with its matched EPRO amplifier, the system is factory-calibrated, allowing for direct engineering unit (microns or mils) readout. This plug-and-play compatibility reduces commissioning complexity and ensures measurement accuracy, which is paramount for reliable protection.

Application Cases and Industry Value:

Case Study: Gas Turbine Generator Protection in a Power Plant.

A combined-cycle power plant relied on a 200 MW gas turbine. Vibration on the #2 bearing was trending upwards. The EPRO PR6423/003-030 probes installed at the bearing provided continuous data to the MMS 6000 monitoring system. Advanced analysis of the vibration signal (frequency spectrum) from the probe indicated a sub-synchronous frequency component, a classic sign of oil whirl instability. Based on this early warning, engineers adjusted bearing parameters during the next scheduled outage. The chief engineer noted: “The data from the PR6423 probes didn’t just tell us vibration was high; it diagnosed the cause. This allowed a targeted, planned intervention, avoiding a potential forced outage that would have cost over $500.000 per day in lost generation.”

Case Study: Petrochemical Centrifuge Train Monitoring.

A large centrifugal compressor train in a refinery, comprising a steam turbine driver, a gearbox, and two compressors, was instrumented with EPRO PR6423/003-030 probes at every radial bearing. During startup, one compressor showed high vibration. The proximity probes clearly showed the shaft was not centered in the bearing (abnormal DC gap) and had high 1X RPM vibration (AC). This pointed to misalignment rather than imbalance. The maintenance lead stated: “The proximity probes gave us the clearest picture. The position (DC gap) data from the PR6423 was as critical as the vibration data. It confirmed misalignment, allowing us to correct it immediately. Without that, we might have wrongly balanced the rotor, wasting days and not fixing the root cause.”

Related Product Combination Solutions:

EPRO PR6424 Converter: The dedicated 2-wire signal conditioner/amplifier that powers the PR6423/003-030 probe and converts its raw signal into standard 4-20 mA and 1-5V/0-10V outputs for vibration and position.

EPRO MMS 6000/MMS 6350 Monitor: A modular, rack-mounted monitoring system that can directly accept signals from PR6423 probes (via internal cards) to provide display, alarms, and relay outputs.

EPRO PR 9376 Converter: A newer, versatile signal conditioner compatible with PR6423 probes, offering enhanced diagnostics and communication options.

Extension Cables (e.g., PR 6426-001-030): 5-meter extension cables used to extend the distance between the probe and the amplifier when the 5m integrated cable is insufficient.

Proximity Probe Accessories: Mounting hardware, BNC connectors, and stainless steel mounting nuts for secure installation of the PR6423/003-030.

Keyphasor® Probe (e.g., PR6423/000-030): A similar probe dedicated to measuring shaft speed and phase reference (once-per-revolution pulse), essential for vibration phase analysis alongside the vibration probes.

Axial Position Probe (e.g., PR6423/00x-0xx): Similar probes used in a thrust bearing configuration to measure shaft axial (thrust) position, often used in tandem with radial vibration probes.

Installation, Maintenance, and Full-Cycle Support:

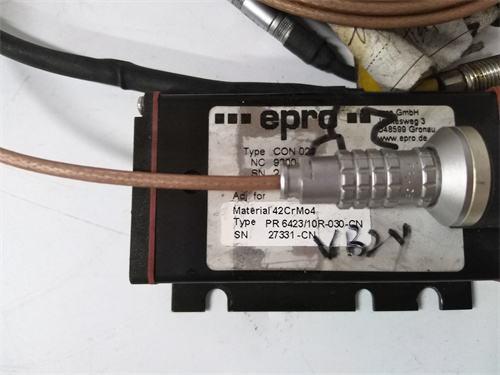

Installation is critical for accurate measurement. The PR6423/003-030 probe must be mounted securely in a threaded hole in a bearing housing, with its tip positioned at the correct gap (typically the electrical “center” or “null” point, e.g., 2mm) from a smooth, clean shaft target area. The target area must be free of scratches, grooves, or material changes. The integrated cable must be properly routed, secured, and connected to the amplifier. The final gap is set and verified using a micrometer and the amplifier’s “Gap Voltage” reading.

Maintenance is primarily preventive. The probe tip should be inspected periodically for physical damage or buildup. The most common issues are cable damage from abrasion or improper installation leading to erratic signals. The system’s calibration (probe and amplifier as a pair) should be verified during major overhauls. Replacement involves unscrewing the old probe, installing the new PR6423/003-030. and re-setting the gap. The system may need to be re-calibrated if the probe is not replaced with an identical, pre-calibrated unit.

We supply the genuine EPRO (Baker Hughes) PR6423/003-030 proximity transducer. Our technical support includes guidance on proper probe selection, installation best practices, and integration with monitoring systems to ensure you achieve reliable and accurate machine protection.

Protect your critical assets with precise, reliable monitoring. Contact us for the genuine EPRO PR6423/003-030 proximity probe and ensure the health of your rotating machinery.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: