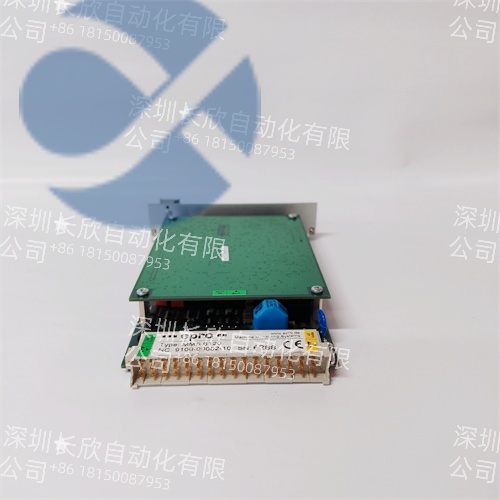

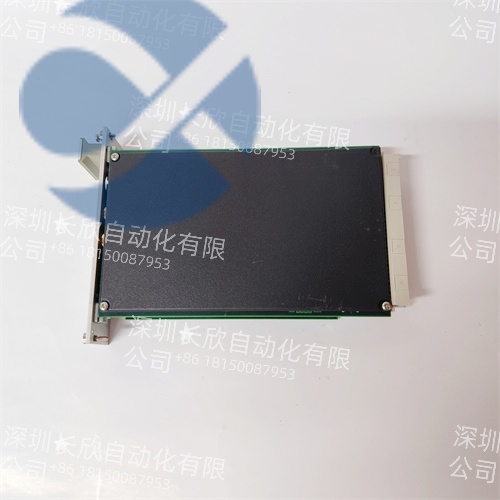

Description

Application Scenarios

At a natural gas processing plant in Texas, an aging centrifugal compressor experienced unexplained shutdowns due to high vibration trips. Legacy monitoring systems lacked diagnostic detail, leading to costly guesswork during outages. Engineers installed the MMS6120 to replace obsolete rack-based monitors, connecting it directly to existing Bently Nevada-style proximity probes. Within hours, the MMS6120’s time-waveform and spectrum trending revealed a developing 1× imbalance combined with bearing wear signatures. Maintenance was scheduled during a planned turnaround—avoiding a potential $ 2M failure. Post-repair, the MMS6120 continued providing 4–20 mA vibration trends to the DCS, enabling predictive analytics and reducing unplanned downtime by 65%.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Dual-Function Signal Conditioning – The MMS6120 integrates full Proximitor-like electronics for each channel, eliminating the need for external signal conditioners when using eddy-current probes—reducing wiring complexity and cabinet space by up to 50%.

Innovation Point 2: Simultaneous Protection and Process Integration – Unlike basic trip modules, the MMS6120 provides both hardwired relay outputs for immediate shutdown and 4–20 mA signals for DCS/SCADA trending—bridging machine protection with operational intelligence.

Innovation Point 3: Onboard Time-Domain Diagnostics – Beyond RMS values, the MMS6120 captures time-waveform snapshots during alarms, enabling engineers to distinguish between imbalance, misalignment, looseness, or resonance—without needing a separate analyzer.

Innovation Point 4: Hot-Swappable & Field-Configurable – Parameters like sensor type, alarm thresholds, and output scaling are set via Modbus or front-panel software—no DIP switches. Modules can be replaced under power in redundant systems, minimizing risk during maintenance.

Application Cases and Industry Value

In a European combined-cycle power plant, steam turbine bearing degradation went undetected for months due to outdated single-threshold monitors. After retrofitting all critical machines with MMS6120 units, operators gained access to continuous gap voltage and filtered vibration trends. Early detection of oil whirl in a #3 bearing allowed intervention before catastrophic failure—saving an estimated €1.8M in repair and lost generation. Similarly, a Middle Eastern desalination facility uses MMS6120 modules on high-pressure RO feed pumps, where salt-laden air accelerates bearing wear. The system’s 4–20 mA outputs feed into their ABB 800xA DCS, triggering automatic lubrication cycles when vibration exceeds baseline—extending mean time between failures by 3×.

Related Product Combination Solutions

MMS6110: Single-channel version of the MMS6120 for cost-sensitive applications

MMS6850: Rack-mounted master module that aggregates data from multiple MMS6120 units

PR9260/00: High-temperature eddy-current probe compatible with MMS6120 inputs

MMS6210: Speed and phase reference module for order tracking with MMS6120

EPRO MMS Software Suite: Configuration, trending, and alarm management platform

MMS6410: Temperature monitoring module for integrated thermal + vibration health assessment

Bently Nevada 3300 XL 8mm: Industry-standard probe often paired with MMS6120

Fluke Accelix Platform: Cloud-enabled reliability ecosystem integrating MMS6120 data

Installation, Maintenance, and Full-Cycle Support

The MMS6120 installs in seconds on a DIN rail within control panels near monitored machinery. Wiring follows standard practices: connect -24 V DC power, link proximity probes to input terminals, and route 4–20 mA and relay outputs to the safety PLC or DCS. No external power supplies are needed for sensors—the MMS6120 provides regulated probe drive current. Commissioning is streamlined via free PC software over RS-485. allowing engineers to auto-detect probe range, set alarm levels, and simulate faults for validation.

Routine maintenance involves periodic verification of alarm relays and analog output accuracy—tasks supported by built-in test modes. The module logs last-trip data (including timestamp and waveform), which aids root-cause analysis. With no moving parts and conformal-coated PCBs, the MMS6120 operates reliably in environments with dust, humidity, and temperatures from -20°C to +60°C. Our technical team offers lifecycle support—from system design and API compliance review to remote diagnostics and firmware updates. All units are calibrated and tested against ISO 16063 standards before shipment.

Contact us for a robust, future-ready machinery protection strategy with the MMS6120—where precision monitoring meets industrial resilience to keep your critical assets running safely and efficiently.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: