Description

Product Overview

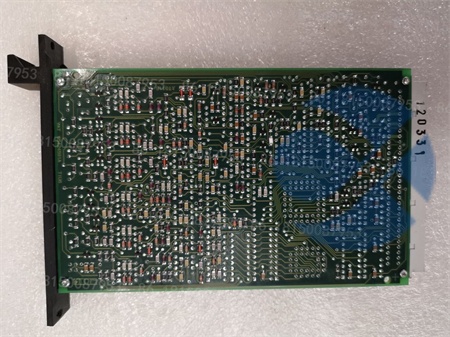

The METSO VALMET AUTOMATION A413110 BOARD0 is a dedicated digital input(DI)module designed for integration within Valmet’s advanced DNA distributed control system(DCS),widely deployed in pulp and paper,power,and process industries.As a field-replaceable unit within Valmet’s I/O architecture,the A413110 BOARD0 serves as a critical interface between field-level sensors and the central automation system,enabling real-time monitoring of discrete status signals such as valve positions,motor run feedback,emergency stops,level switches,and equipment alarms.

Engineered for high reliability in harsh industrial environments,this module provides 16 isolated digital input channels capable of accepting 24 VDC signals from both sinking and sourcing field devices.The METSO A413110 BOARD0 ensures noise immunity and electrical protection through optical isolation,safeguarding the control system from voltage transients,ground loops,and electromagnetic interference(EMI)common in large-scale industrial plants.It operates as part of a modular I/O station connected via redundant Ethernet or PROFIBUS to the Valmet DNA control network,supporting deterministic data exchange for fast process response.

Originally developed under the Metso Automation brand and now part of Valmet Automation’s legacy product line,the A413110 BOARD0 is commonly found in existing Valmet DNA installations where backward compatibility and long-term support are essential.Its plug-and-play design allows for quick replacement during maintenance,minimizing production downtime in continuous processes such as paper machine operation,stock preparation,and chemical recovery.As a trusted component in mission-critical control systems,the METSO A413110 BOARD0 plays a vital role in ensuring operational safety,process visibility,and efficient automation management.

Technical Specifications

Product Model A413110 BOARD0

Manufacturer METSO(now Valmet Automation)

Product Type Digital Input(DI)Module

Series/Platform Valmet DNA Distributed Control System

Function 16-Channel Digital Input Module

Number of Inputs 16 channels

Input Signal Type 24 VDC(sinking or sourcing)

Input Voltage Range 18–30 VDC

Input Current~3.5 mA per channel

Isolation Optical isolation(500 V AC channel-to-bus)

Response Time<10 ms

Power Supply 24 VDC via backplane(from Valmet DNA I/O station power module)

Bus Interface Valmet DNA Fieldbus(Ethernet or PROFIBUS DP)

Operating Temperature 0°C to+60°C

Storage Temperature-25°C to+70°C

Humidity 5%to 95%non-condensing

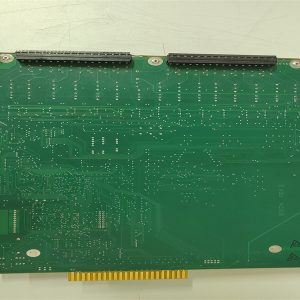

Installation DIN rail mount(35 mm)in Valmet DNA I/O cabinet

Mounting Type Snap-on rail mount with backplane connector

Certifications CE,UL,CSA,IEC 61000-6-2(EMC Immunity),IEC 61000-6-4(Emissions)

Compatibility Valmet DNA R11 and later versions,Valmet I/O stations(e.g.,XA-10,XA-20)

Main Features and Advantages

The METSO VALMET AUTOMATION A413110 BOARD0 delivers robust performance as a digital signal acquisition module within the Valmet DNA ecosystem.Its 16 optically isolated input channels ensure high noise immunity and system protection,making it ideal for deployment in electrically noisy environments such as paper mills,recovery boilers,and pump rooms.Each input is individually protected against overvoltage and short circuits,enhancing long-term reliability and reducing maintenance costs.

One of the key advantages of the A413110 BOARD0 is its seamless integration with the Valmet DNA control platform.It automatically registers with the system upon installation,with configuration handled through Valmet DNA Engineer tool,eliminating the need for manual addressing or DIP switch setup.This plug-and-play capability reduces commissioning time and minimizes configuration errors.The module supports diagnostic feedback,allowing operators to detect wiring faults,signal loss,or module failure through the HMI or SCADA interface.

Designed for continuous operation,the METSO A413110 BOARD0 features a rugged PCB construction and conformal coating(in some variants)to resist moisture and chemical exposure—common challenges in pulp and paper environments.Its compact DIN rail footprint enables high-density I/O configurations,optimizing cabinet space.With proven field reliability and long-term availability as a spare part,the A413110 BOARD0 is a dependable solution for maintaining the integrity and responsiveness of industrial automation systems in critical process applications.

Application Field

The METSO VALMET AUTOMATION A413110 BOARD0 is primarily used in pulp and paper manufacturing facilities where Valmet DNA is the standard control system.It monitors discrete signals across various process sections,including the stock preparation plant,paper machine,coating station,reel,and winder.For example,it tracks the status of slice valves,fan pumps,vacuum pumps,and doctor blades on a paper machine,providing real-time feedback to the control system for automated adjustments and alarm generation.

In power and recovery boilers,the A413110 BOARD0 interfaces with safety interlocks,flame scanners,and burner management systems,ensuring safe startup and shutdown sequences.It also plays a role in chemical recovery and lime kiln operations by monitoring conveyor status,hopper levels,and scrubber activation.Beyond pulp and paper,the module is deployed in board mills,tissue machines,and bioenergy plants where Valmet automation systems are installed.

Additionally,the METSO A413110 BOARD0 supports retrofits and brownfield upgrades,serving as a reliable replacement for aging I/O modules in existing Valmet DNA installations.Its compatibility with modern Valmet control networks ensures that legacy systems can continue operating efficiently without requiring a full control system overhaul.Whether monitoring a single pump or an entire production line,the A413110 BOARD0 provides the signal integrity and reliability needed for safe,efficient,and uninterrupted industrial operations.

Related Products

Valmet A413111 BOARD0–16-channel digital output(DO)module,often used alongside the A413110 BOARD0.

Valmet A413120 BOARD0–Analog input module(4–20 mA)for temperature,pressure,and flow signals.

Valmet DNA Controller(e.g.,AC31,AC400)–Central processing unit that communicates with the A413110 BOARD0.

Valmet XA-10/XA-20 I/O Station–Field cabinet housing the A413110 BOARD0 and other I/O modules.

Valmet A413100 BOARD0–Power supply module providing 24 VDC to the I/O station.

Valmet A413130 BOARD0–Analog output module for control signal distribution.

Valmet DNA Engineer/Operate–Configuration and HMI software for system setup and monitoring.

Valmet A413150 BOARD0–Communication interface module(PROFIBUS,Modbus).

Valmet A413112 BOARD0–High-speed counter or pulse input module for specialized applications.

Valmet Spare Part Kit A413000-SERIES–Collection of common spares including the A413110 BOARD0 for maintenance.

Installation and Maintenance

Pre-installation preparation:Before installing the METSO VALMET AUTOMATION A413110 BOARD0,ensure the I/O cabinet is de-energized and locked out.Verify that the DIN rail is secure and the backplane connector is clean and undamaged.Check that the 24 VDC power supply from the station power module(e.g.,A413100 BOARD0)is stable.Align the module with the guide rails and firmly seat it onto the backplane connector.Secure with retaining clips if provided.Wire field devices(e.g.,limit switches,sensors)to the terminal block,observing correct polarity and using shielded cables with shield grounded at one end.Double-check all connections before restoring power.

Maintenance recommendations:Regularly inspect the A413110 BOARD0 for loose terminals,dust accumulation,or signs of overheating.Monitor input status via Valmet DNA HMI to detect signal inconsistencies or intermittent faults.Use the module’s diagnostic LEDs(typically per-channel and module status)to verify operation.In high-humidity environments,ensure cabinet heaters and seals are functional to prevent condensation.The module requires no calibration or firmware updates under normal conditions.For preventive maintenance,perform periodic functional tests during planned shutdowns.Keep spare modules on-site to minimize downtime in case of failure.

Product Guarantee

Every METSO VALMET AUTOMATION A413110 BOARD0 is guaranteed to be a genuine,factory-tested component,fully compatible with Valmet DNA control systems.We provide a 12-month warranty against manufacturing defects,ensuring reliability and performance in industrial applications.Our technical support team offers expert assistance for installation,configuration,and troubleshooting,ensuring seamless integration into your automation infrastructure.Whether used as a spare,replacement,or part of a system upgrade,the A413110 BOARD0 is backed by a commitment to authenticity,durability,and long-term serviceability.By delivering high-quality,tested modules with comprehensive support,we help pulp,paper,and process industries maintain continuous,safe,and efficient operations.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

-1-300x300.jpg)