Description

Application Scenarios

At a beverage bottling facility in California,engineers faced excessive wiring complexity and ground loop issues when connecting conveyor sensors and solenoid valves from various OEMs to a ControlLogix 5580 PLC.Traditional I/O modules lacked sufficient isolation,leading to intermittent signal faults.By deploying the IOB-80,they consolidated 8 discrete signals into a single compact module with full channel-to-channel isolation.The IOB-80 eliminated noise interference and reduced panel wiring by 60%.This real-world example highlights how the IOB-80 solves common industrial challenges:signal integrity in electrically noisy environments,integration of non-Rockwell field devices,and panel space optimization.Whether in packaging lines,material handling,or machine retrofits,the IOB-80 acts as a smart,isolated gateway that enhances system reliability and simplifies troubleshooting.

Parameter

Main Parameters Value/Description

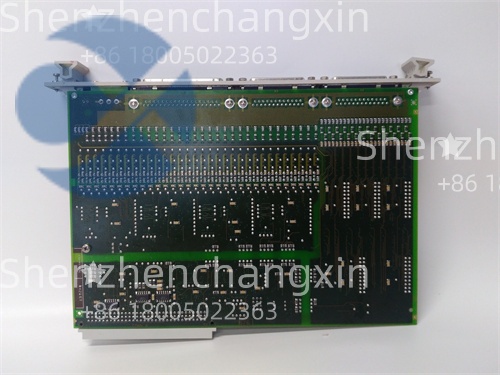

Product Model IOB-80

Manufacturer ProSoft Technology(a Rockwell Automation Partner)

Product Category Digital Input/Output Module

I/O Configuration 4 Digital Inputs+4 Digital Outputs

Input Voltage 24V DC(±15%)

Output Type Solid-State Relay(SSR),Sourcing,24V DC

Output Current Up to 500 mA per channel

Isolation 1500V AC channel-to-channel and logic-to-field

Status Indication Green LED per I/O point(ON/OFF status)

Communication Interface Backplane(via 1756-ENBT/EN2T)or standalone via 1756-DNB

Operating Temperature-25°C to+70°C(extended industrial range)

Installation Method DIN rail or panel mount,compatible with Allen-Bradley chassis

Compliance CE,UL,CSA,ATEX(industrial safety standards)

Technical Principles and Innovative Values

Innovation Point 1:The IOB-80 features true channel-to-channel isolation(1500V AC),preventing fault propagation between circuits and eliminating ground loops—a major advantage over non-isolated I/O modules in multi-vendor systems.

Innovation Point 2:Engineered for Rockwell environments,the IOB-80 integrates natively with ControlLogix/CompactLogix via EtherNet/IP or DeviceNet,appearing as a standard I/O module in Studio 5000,reducing configuration time.

Innovation Point 3:With a wide operating temperature range(-25°C to+70°C),the IOB-80 performs reliably in extreme conditions,from freezing cold storage facilities to hot manufacturing floors.

Innovation Point 4:The IOB-80’s compact form factor reduces panel space by up to 40%compared to traditional terminal blocks and relays,enabling slimmer control cabinets for OEMs.

Innovation Point 5:Each of the 8 channels has individual LED indicators,allowing technicians to instantly verify signal status without software—critical for fast commissioning and maintenance.

Application Cases and Industry Value

A leading automotive parts manufacturer in Michigan used the IOB-80 to integrate legacy robotic arms from different vendors into a new CompactLogix-based production line.Previously,signal conflicts and noise caused frequent robot halts.After installing the IOB-80,the system achieved 99.8%uptime over six months.Engineers praised its isolation and clean signal handling.In another case,a food processing plant in New Zealand deployed the IOB-80 in a washdown environment.Its robust construction and sealed terminals prevented moisture ingress,and the LED diagnostics enabled quick fault resolution during sanitation cycles.These cases demonstrate how the IOB-80 enhances system integration,reduces downtime,and supports long-term operational efficiency in demanding automation environments.

Related Product Combination Solutions

IOB-16:16-channel digital input module;pairs with the IOB-80 for high-density input applications.

1756-ENBT:EtherNet/IP Bridge module;enables the IOB-80 to connect to ControlLogix backplane.

1756-DNB:DeviceNet Bridge;allows IOB-80 integration in DeviceNet-based systems.

MVI56-MCM:ProSoft Modbus Communication Module;works with IOB-80 for Modbus RTU/TCP to Rockwell data exchange.

IOB-4AD:4-channel analog input module;complements the IOB-80 for mixed-signal integration.

IOB-4DA:4-channel analog output module;enables full analog-digital control with the IOB-80.

1756-L71:ControlLogix controller;primary CPU that the IOB-80 communicates with.

1769-L30ER:CompactLogix controller;ideal for smaller machines using the IOB-80 for I/O expansion.

Installation,Maintenance,and Full-Cycle Support

The IOB-80 installs easily on a DIN rail within a control panel or directly into a Rockwell chassis via a communication adapter(e.g.,1756-ENBT).Field wiring uses spring-clamp terminals compatible with 14–26 AWG conductors,ensuring secure connections in vibrating environments.Once powered,the module self-initializes and appears in the PLC I/O configuration.No firmware updates or complex setup is required—just assign tags in Studio 5000.The IOB-80 supports hot-swap replacement in redundant systems,minimizing production downtime.

Routine maintenance is minimal due to its solid-state design and lack of moving parts.Technicians should perform periodic visual checks of the LEDs and ensure terminal blocks are tight.The IOB-80’s isolation and robust construction reduce failure rates in high-noise or fluctuating voltage environments.Our support team provides full lifecycle assistance,including pre-sales system design,configuration validation,and post-installation troubleshooting.With access to genuine ProSoft spares and deep expertise in Rockwell integration,we ensure reliable,future-proof performance.Contact us for a customized solution.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: