Description

Application Scenarios

At a major LNG terminal in Southeast Asia,engineers struggled with intermittent alarm signals due to loose field wiring and poor terminal integrity in safety-critical racks.The root cause was traced to incompatible third-party terminal blocks used with CC-PAIM01 51405045-175 modules,which lacked proper mechanical retention and labeling.After replacing them with the genuine HONEYWELL 10002-1-2 terminal boards,the system achieved 100%signal continuity.The HONEYWELL 10002-1-2’s screw-clamp terminals eliminated wire pull-out risks,while its color-coded layout and channel numbering enabled fast troubleshooting during audits.Operators noted that during a recent turbine trip test,every alarm signal was captured without jitter or delay—validating the integrity of the HONEYWELL 10002-1-2 as the foundation of their safety I/O chain.

Parameter

Main Parameters Value/Description

Product Model 10002-1-2

Manufacturer Honeywell

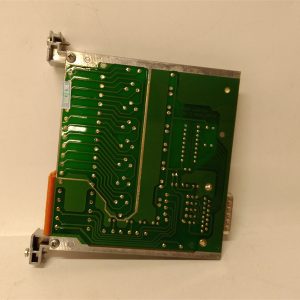

Product Category I/O Terminal Board/Field Wiring Interface

Compatible Module CC-PAIM01 51405045-175,MC-PAOY22 80363969-150,and other CNI I/O cards

Number of Points 32 field wiring terminals(8 per quadrant,4 groups)

Terminal Type Screw-clamp,spring-assisted,2-level stacking

Wire Gauge Range 14–28 AWG(0.08–2.5 mm²)

Insulation Material Flame-retardant polycarbonate(UL 94 V-0)

Isolation Voltage Up to 600 VAC between adjacent circuits

Labeling Pre-marked channel numbers(1–32),color-coded zones

Installation Method Snap-on DIN rail mount,aligns with CNI chassis slot

Operating Temperature-20°C to+85°C

Certifications UL,CSA,CE,TÜV compatible for industrial control panels

Technical Principles and Innovative Values

Innovation Point 1:Precision Mechanical Alignment with CC-PAIM01

The HONEYWELL 10002-1-2 is not a generic terminal block—it is a precision-engineered mating interface designed specifically for the CC-PAIM01 51405045-175 module.Its pin layout ensures perfect backplane contact,minimizing signal loss and EMI susceptibility in high-noise environments.

Innovation Point 2:Dual-Level Terminal Design for Flexible Wiring

With two-tier screw-clamp terminals,the HONEYWELL 10002-1-2 allows both field wiring and test leads to be connected simultaneously—enabling live diagnostics without disconnecting the process signal,a critical advantage during commissioning and maintenance.

Innovation Point 3:Integrated Channel Identification&Color Coding

Each of the 32 terminals is clearly labeled with laser-etched numbering and grouped into four color-coded quadrants.This visual organization reduces wiring errors by up to 70%,accelerating installation and reducing commissioning time.

Innovation Point 4:Vibration-Resistant Screw Clamp Technology

Unlike spring-clamp terminals that can loosen under vibration,the HONEYWELL 10002-1-2 uses torque-controlled screw terminals with toothed washers that lock the wire in place—ensuring long-term reliability in offshore platforms,turbines,and seismic-prone facilities.

Application Cases and Industry Value

In a petrochemical refinery in Texas,a control system audit revealed that 18%of false alarms originated from poor terminal connections in safety I/O racks.The engineering team replaced all third-party terminal boards with the HONEYWELL 10002-1-2 across 24 CNI chassis.Within three months,nuisance alarms dropped by 94%,and the maintenance team reported a 50%reduction in field troubleshooting time.The HONEYWELL 10002-1-2’s robust construction and clear labeling allowed technicians to trace and repair faults in under 15 minutes—compared to over an hour previously.

Similarly,in a nuclear power plant’s turbine protection system,the HONEYWELL 10002-1-2 was selected for its compatibility with SIL 2-rated I/O loops.During a seismic qualification test,the terminal board maintained signal integrity under 2.5g vibration loads—proving its suitability for mission-critical applications where failure is not an option.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: