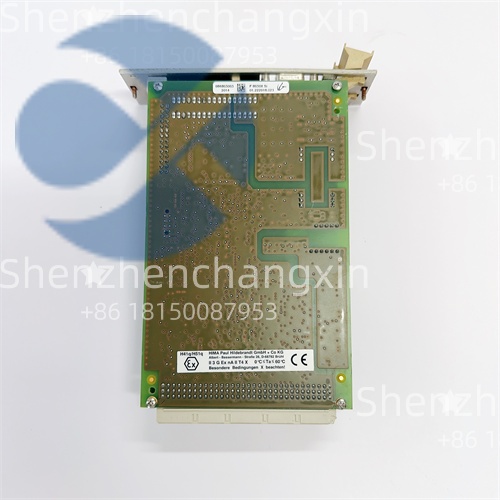

Description

Application Scenarios:

In a high-pressure hydrocarbon gas compression facility, the emergency shutdown (ESD) system must react with absolute certainty to a manual emergency stop command or a signal from a gas detection sensor. A failure of the input circuit to recognize this command could have catastrophic consequences. The HIMA F8650X 984865065 module is the trusted interface for these critical signals. Installed in the safety controller rack, each of its 16 channels connects to a normally closed (NC) contact from a safety device. The module doesn’t just read the signal; it continuously performs internal diagnostics, cross-checks, and pulse tests to verify the integrity of the entire loop, including the field wiring and the sensor contact itself. When an operator hits the emergency stop, the F8650X reliably detects the contact opening within milliseconds, validates the signal, and communicates the “trip” demand to the safety logic solver. It addresses the paramount pain point of fail-safe signal acquisition, ensuring that safety demands are never missed due to a covert hardware fault, thereby protecting people, assets, and the environment.

Technical Principles and Innovative Values:

The HIMA F8650X is engineered on the principle of functional safety, where reliability is mathematically assured through hardware design and continuous self-monitoring.

Innovation Point 1: HIQuad Architecture with 2oo2D Evaluation. The module’s core innovation lies in its “HIQuad” design. Each input channel is processed by two independent acquisition chains within the module. A diagnostic unit (the “D” in 2oo2D) continuously compares these two signals. Any discrepancy (e.g., one chain reads ‘1’ and the other ‘0’) indicates an internal fault, triggering a safe state. This hardware-based, diverse redundancy ensures a very high Safe Failure Fraction (SFF) and is fundamental to achieving SIL 3 capability.

Innovation Point 2: Advanced Field Circuit Diagnostics. Beyond internal checks, the F8650X actively monitors the health of the connected field circuit. It can perform pulse testing to detect latent faults like cable degradation, short circuits between wires, or welded contacts on safety switches. This proactive diagnostics capability transforms the module from a simple signal reader into an intelligent sentinel that can warn of impending failures before a safety demand occurs, enabling predictive maintenance of the safety loop itself.

Innovation Point 3: Flexible and Transparent Configuration. The module offers flexible configuration per channel group (e.g., definition of normal state, test pulse behavior) via HIMA’s dedicated safety engineering tool. More importantly, it provides detailed, channel-specific diagnostic information that is communicated to the safety CPU and can be relayed to a higher-level control or asset management system. This transparency is crucial for operators and maintenance personnel to quickly pinpoint the exact location and nature of a fault.

Application Cases and Industry Value:

Case Study: Modernization of a Fire & Gas (F&G) System in an LNG Terminal

An aging LNG export terminal needed to upgrade its Fire & Gas detection system to meet modern safety standards. The existing system had unreliable diagnostics, making it difficult to confirm the health of gas detector circuits. The new system required SIL 2 capability for gas detection zones and needed to integrate seamlessly with the new central ESD.

The project selected a HIMA safety controller with F8650X 984865065 modules to handle the signals from over 100 new point-type gas detectors. Each detector’s relay contact was wired to a dedicated channel on the F8650X. The modules’ wire-break detection feature ensured any break in the cable to the detector would cause a “fault” alarm, not just a “gas present” signal. During commissioning, the diagnostic capability proved invaluable when it identified a faulty installation where two detector cables were inadvertently shorted together—a fault the old system would never have detected.

Result: The HIMA F8650X modules provided the terminal with a highly reliable and diagnosable input layer for their critical F&G system. Maintenance teams now receive precise alerts (e.g., “Channel 14. Group 2: Wire Break”) instead of generic system faults, slashing troubleshooting time. The engineering manager stated, “The diagnostic depth of the F8650X inputs gives us unprecedented visibility into the health of our safety loops. It’s not just about reacting to a hazard; it’s about knowing with certainty that the system is ready to react.” This enhanced integrity and maintainability directly supports the facility’s safety case and operational uptime.

Related Product Combination Solutions:

The HIMA F8650X operates within a comprehensive safety system. Key related components include:

HIMA F35 or F45 CPU: The central safety logic solver (e.g., F35 AP or F45 AP) that processes the input data from the F8650X and executes the safety logic.

HIMA F8651X / F8652X: The complementary digital output (F8651X) and analog input (F8652X) modules from the same HIQuad series, used to build a complete safety I/O subsystem.

HIMA F8655X: A digital input module with a high diagnostic coverage (HFT=1) variant for even higher safety availability requirements.

HIMA Power Supply Module (e.g., F-PSM): The redundant, fault-tolerant power supply unit that provides the clean, reliable 24V power to the rack and all I/O modules like the F8650X.

HIMA Safety Engineering Software (Safety Manager): The configuration and programming tool used to parameterize the F8650X channels, set diagnostics, and integrate the module into the application logic.

HIMA Communication Modules (e.g., for PROFIsafe, Modbus TCP): Modules that allow the safety controller (and the data from the F8650X) to communicate safely with standard PLCs or DCS systems.

Installation, Maintenance, and Full-Cycle Support:

Installation of the HIMA F8650X module must be performed by qualified personnel following strict safety guidelines. It is designed for insertion into a HIQuad baseplate within a HIMA safety controller rack. Terminals for field wiring are typically on a separate, pluggable terminal block, allowing for easy module replacement without disturbing field wiring. Configuration is performed offline using the Safety Manager software and downloaded to the CPU, which then distributes parameters to the I/O modules.

Routine maintenance involves monitoring the system diagnostics via the engineering software or any connected HMI. The module’s advanced self-diagnostics will report any detected faults. It is crucial to respond to diagnostic warnings (like “field wire break”) promptly, as they indicate a degradation in the safety loop’s integrity. Module replacement is straightforward: after putting the associated part of the SIS into a safe state (if required), the faulty module can be unplugged and a new one inserted. The configuration is automatically loaded from the CPU.

We provide full-cycle support for the HIMA F8650X 984865065. from initial system design consultation to ensure it meets your safety performance requirements (SIL), through supply of genuine HIMA components, to technical support for configuration and integration. Our expertise helps ensure your safety system is implemented correctly, maintains its certified integrity, and delivers long-term, reliable protection for your most critical processes.

Designing or maintaining a Safety Instrumented System (SIS)? Contact us for expert support and reliable supply of the HIMA F8650X 984865065 safety input module and the complete HIMA safety solution.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: