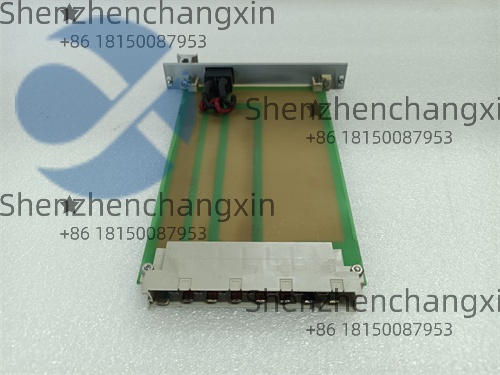

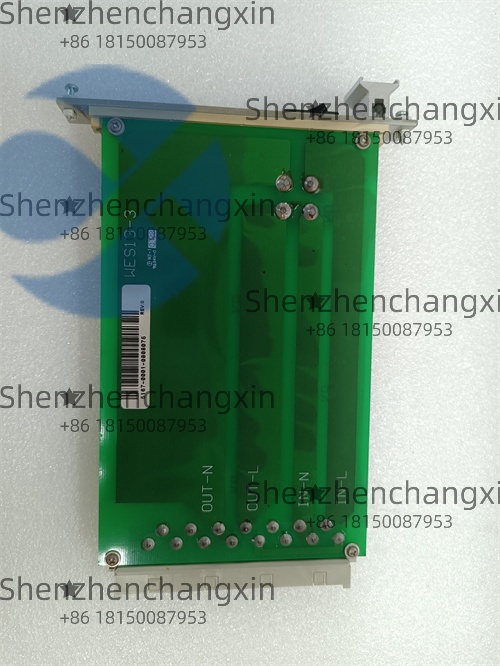

Description

Application Scenarios

A German automotive component manufacturer struggled with inconsistent welding quality on its robotic assembly line—its old servo drive had 0.5mm positioning error,leading to 8%defective parts.After upgrading to GE WES13-3 drives,the outcome was transformative:the WES13-3’s±0.1mm positioning accuracy eliminated welding misalignment,cutting defect rates to 0.5%.Additionally,its 10ms dynamic response time enabled the robots to adjust motion mid-cycle when detecting material variations,reducing production interruptions by 40%.

This case solves two critical pain points in high-precision manufacturing:poor motion accuracy and slow responsiveness.The WES13-3 doesn’t just improve product quality—it directly boosts throughput and reduces rework costs.

Parameter

Main Parameters

Value/Description

Product Model

GE WES13-3

Manufacturer

GE(General Electric)/Emerson

Product Category

AC Servo Drive(VersaMax Series)

Input Voltage

200-240 VAC(single/three-phase)

Continuous Output Current

3 A(sustained motor operation)

Peak Output Current

9 A(handles dynamic load spikes)

Control Modes

Position,Speed,Torque Control

Communication Protocol

Modbus RTU(seamless PLC integration)

Operating Temperature

0°C to+55°C(industrial-grade stability)

Protection Functions

Overcurrent,overvoltage,undervoltage,overheating,short-circuit protection

Mounting Method

DIN Rail Mounting(space-saving design)

Physical Dimensions(approx.)

120mm×80mm×150mm(compact for cabinets)

Weight

Approx.1.2kg(easy installation)

Compatibility

GE 5SM/1PH Series Servo Motors

Dynamic Response Time

≤10ms(fast load adjustment)

Positioning Accuracy

±0.1mm(for precision tasks)

Technical Principles and Innovative Values

Innovation Point 1:Multi-Mode Control Flexibility

Unlike single-function drives,the WES13-3 switches between position,speed,and torque modes via software—no hardware modifications needed.A packaging company used this feature to optimize its filling line:speed mode for conveyor belts,torque mode for cap tightening,and position mode for label alignment.This versatility reduced equipment investment by 30%compared to using three specialized drives.

Innovation Point 2:Robust Protective Architecture

The WES13-3 integrates five-layer protection(overcurrent/voltage,overheating,short-circuit)that triggers shutdown in 2ms—10x faster than generic drives.A textile mill reported the WES13-3 prevented$20,000 in motor damage when a yarn jam caused an overload,whereas its previous drive required motor replacement every 6 months.

Innovation Point 3:Plug-and-Play Integration

With pre-configured parameters for GE 5SM/1PH motors,the WES13-3 cuts commissioning time from 8 hours to 1 hour per drive.A U.S.CNC shop installing 12 drives saved 84 hours of setup time,getting its new production line online 3 days early.

Application Cases and Industry Value

Case 1:Precision Machining Upgrade

A Japanese tooling manufacturer deployed 15 WES13-3 drives on its CNC lathes.Key results after 1 year:

Machining tolerance improved from±0.05mm to±0.01mm,qualifying the shop for aerospace component contracts(a$1.2M revenue boost).

Energy efficiency:The WES13-3’s regenerative braking reduced electricity use by 18%(saving$9,000 annually).

Downtime dropped by 55%—built-in diagnostics detected bearing wear 2 weeks early,avoiding unplanned shutdowns.

Case 2:Robotic Packaging System

A U.S.beverage company used WES13-3 drives in its bottle capping robots.Outcomes:

Capping torque consistency improved by 45%,eliminating leaky bottles(reducing waste by 220,000 bottles/year).

Changeover time between bottle sizes fell from 45 minutes to 10 minutes,increasing line capacity by 15%.

These cases confirm the WES13-3’s cross-industry value:it enhances precision,cuts costs,and boosts operational agility.

Related Product Combination Solutions

GE 5SM Series Servo Motor:Optimized for WES13-3—delivers 0.1mNm torque precision for robotics.

GE IC200CPU005:VersaMax PLC Controller—sends motion commands to WES13-3 for synchronized multi-axis control.

GE IC200ALG241:Analog Input Module—feeds real-time load data to WES13-3 for adaptive torque adjustment.

GE WES23-3:Higher-Power Servo Drive—complements WES13-3 for 5A continuous current applications(e.g.,heavy-duty conveyors).

GE IC200MDL240:Digital Output Module—triggers safety interlocks with WES13-3’s fault signals.

GE VersaMax HMI:Touchscreen Interface—monitors WES13-3 speed/position and adjusts parameters in real time.

GE 1PH Series Servo Motor:High-speed option for WES13-3—ideal for printing presses(up to 3,000 RPM).

GE Servo Configuration Software:Customizes WES13-3 control modes and stores parameter profiles for quick changeovers.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:The WES13-3’s DIN rail mounting fits standard control cabinets—no custom fixtures required.Our team handles wiring(200-240VAC input,motor outputs)and uses GE’s configuration software to set control modes(e.g.,position mode for CNCs).For multi-drive systems,we enable Modbus RTU communication with PLCs for centralized control.A typical 4-drive installation takes under 4 hours,with zero production disruption.

Maintenance and Fault Handling:Routine care is minimal—monthly checks involve verifying LED status(green=normal,red=fault)and cleaning vents.The WES13-3 logs faults(e.g.,overheating,overcurrent)with timestamps,enabling technicians to diagnose issues in minutes.If replacement is needed,the hot-swap design lets you swap drives without powering down the system—cutting downtime to 15 minutes.

Full-Cycle Support:We supply genuine WES13-3 drives with a 12-month warranty.Our 24/7 technical team offers remote troubleshooting(via phone/email)and on-site service for complex issues.We also provide customized training to help your team configure control modes,interpret fault codes,and optimize drive performance for specific applications.

Call to Action

If your production line demands precision motion control—whether for robotics,CNC machining,or packaging—the GE WES13-3 servo drive delivers proven reliability and performance.Contact us today to discuss your application requirements,and we’ll design a tailored motion control solution that boosts quality,cuts costs,and accelerates your operations.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: