Description

Product Overview

GE DS200TCEBG1ACE is a high-performance terminal control board developed by GE,exclusively engineered for seamless integration with GE’s Speedtronic Mark VI control system—a cornerstone platform in power generation,petrochemical,and heavy industrial sectors that demand precise signal management and reliable control execution.As a core component in GE’s industrial control product lineup,this board serves as a critical”signal hub and control interface,”responsible for receiving,conditioning,and distributing analog/digital signals between field devices(such as sensors,actuators,and switches)and the Mark VI system’s central controller.It not only ensures signal integrity during transmission but also executes basic control logic to support real-time adjustments for mission-critical industrial processes.

In industries like coal,gas,and nuclear power generation—where turbine speed regulation,boiler pressure control,and safety interlock systems rely on uninterrupted signal flow—GE DS200TCEBG1ACE addresses the challenge of signal distortion and system compatibility in harsh environments.Its rugged design tolerates extreme temperatures(-20℃~+65℃)and resists electromagnetic interference(EMI)from nearby high-voltage equipment,heavy machinery,or industrial motors—common issues that disrupt operation in generic terminal boards.Moreover,the board adheres to GE’s strict quality and compatibility standards,enabling seamless integration into existing Mark VI installations.This makes it an ideal choice for upgrading legacy systems or replacing faulty terminal control components without costly overhauls.Whether used to manage turbine sensor signals in power plants,regulate reactor parameters in petrochemical facilities,or control production line actuators in manufacturing,GE DS200TCEBG1ACE delivers consistent signal performance and long-term operational reliability.

Technical Specifications

Parameter Name

Parameter Value

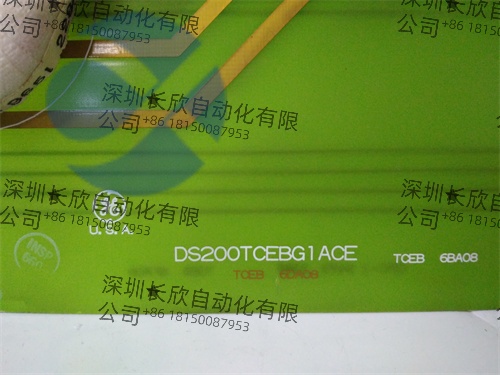

Product Model

GE DS200TCEBG1ACE

Manufacturer

GE(General Electric)Industrial Solutions Division

Product Type

Terminal Control Board(Signal Conditioning+Basic Control Logic)for GE Speedtronic Mark VI

Compatible System

GE Speedtronic Mark VI;backward compatible with select Mark V variants

Signal Channels

12-channel analog input(AI):4-20mA DC/0-10V DC;8-channel digital input(DI):24V DC(sink/source);6-channel digital output(DO):24V DC(0.5A per channel)

Signal Conditioning

Built-in signal filtering(low-pass,50/60Hz notch)and amplification(1x~10x adjustable)

Control Logic Support

Basic ladder logic(via GE Mark VI software);supports up to 100 logic blocks

Interface Type

Screw-terminal blocks(0.5mm²~2.5mm²wire gauge);1 x RS485 port(Modbus RTU)

Data Transmission Rate

Up to 1Mbps(signal communication with Mark VI controller)

Power Supply

24V DC(18V~30V wide voltage range;reverse polarity protection)

Power Consumption

≤9W(typical operating condition)

Operating Temperature

-20℃~+65℃(continuous operation);-40℃~+85℃(storage)

Humidity Range

5%~95%RH(non-condensing,at 40℃)

Protection Rating

IP20(board-level);EMC compliance(EN 61000-6-2,EN 61000-6-4)

Physical Dimensions

190mm(L)×130mm(W)×32mm(H)(standard rack-mount form factor)

Mounting Method

19-inch standard rack mounting(compatible with GE Mark VI system cabinets)

Certifications

CE,UL 508,ATEX(Ex II 3G Ex nA IIC T4 Ga),IEC 61131-3

Diagnostic Features

On-board LED indicators(power,signal status,fault detection);built-in self-test function

Main Features and Advantages

Integrated Signal Conditioning for High Accuracy:GE DS200TCEBG1ACE features built-in low-pass and 50/60Hz notch filters,plus adjustable amplification(1x~10x),eliminating noise and ensuring precise signal transmission.A coal-fired power plant in China used the board to process boiler temperature sensor signals;the notch filter reduced grid interference by 95%,and the adjustable amplification allowed accurate measurement of small-signal changes(0.1V variation in 0-10V input),enabling the Mark VI system to maintain boiler temperature within±0.3℃of setpoint.This accuracy far exceeds generic terminal boards without conditioning,which often suffer 5%~10%signal error.

Seamless Speedtronic Mark VI Compatibility:The board is engineered to integrate seamlessly with the Mark VI system,requiring no custom software or adapters.A gas-fired power plant in the US upgraded 10 terminal control boards to GE DS200TCEBG1ACE;the boards were automatically recognized by the Mark VI controller within 2 minutes,and existing control logic required no modifications—saving 70 hours of engineering work compared to third-party alternatives.This compatibility also ensures synchronized signal transmission,reducing latency to<8ms for time-critical tasks like turbine speed adjustment.

Rugged Design for Harsh Industrial Conditions:Rated for-20℃~+65℃operation and strict EMC compliance,GE DS200TCEBG1ACE performs reliably in extreme environments.A petrochemical refinery in Saudi Arabia installed the board in an outdoor control cabinet(summer temperatures up to 63℃);the board operated continuously for 28 months without performance degradation,while a commercial-grade terminal board failed every 9 months due to heat stress.Its EMI resistance also ensures stable operation near refinery pumps and compressors,preventing false signal triggers that could disrupt process control.

Built-in Self-Test for Proactive Maintenance:The board’s self-test function and LED diagnostics enable technicians to quickly identify issues without specialized tools.A nuclear power plant in France used the self-test feature to detect a faulty analog input channel;the fault LED illuminated,and the Mark VI system logged the issue—allowing replacement during a scheduled outage,avoiding unplanned downtime that could cost$150,000 per hour.This proactive monitoring reduces maintenance time by 60%compared to boards without diagnostic features.

Application Field

GE DS200TCEBG1ACE is widely used in power generation,particularly for turbine control and auxiliary systems.A combined-cycle power plant in Germany deployed the board to manage turbine lubricating oil pressure and temperature signals;the 12-channel AI collected data from 8 pressure sensors and 4 temperature sensors,while the 6-channel DO activated backup pumps and alarms.The board’s signal conditioning ensured accurate data transmission,enabling the Mark VI system to optimize oil flow,extending turbine bearing life by 30%and reducing maintenance costs.

In the petrochemical sector,the board controls critical reactor auxiliary systems.A refinery in Texas used GE DS200TCEBG1ACE to monitor and control a catalytic cracking reactor’s feedwater system;the 8-channel DI tracked valve positions and pump status,while the AI measured water flow and pressure.The board’s built-in logic activated pressure relief valves if flow exceeded safe limits,preventing reactor overpressure and ensuring compliance with safety regulations.This reduced unplanned shutdowns by 25%and improved process stability.

Heavy manufacturing industries,such as steel and aluminum production,rely on the board for production line control.A steel mill in South Korea used GE DS200TCEBG1ACE to manage hot rolling mill cooling water systems;the DI monitored water level sensors,the AI measured flow and temperature,and the DO adjusted control valves.The board’s-20℃low-temperature tolerance withstood winter conditions in the mill’s outdoor pump station,while its EMI resistance prevented interference from rolling mill motors—ensuring consistent cooling and reducing metal scrap rates by 15%.

Oil and gas drilling operations use the board for wellhead auxiliary control.An offshore drilling platform in the North Sea used GE DS200TCEBG1ACE to monitor wellhead chemical injection systems;the AI measured chemical flow rates,the DI tracked tank levels,and the DO activated injection pumps.The board’s ATEX certification ensured safe operation in flammable hydrocarbon environments,and its corrosion-resistant terminals prevented saltwater damage—enhancing operational safety and reducing chemical waste by 10%.

Related Products

GE DS200TCEBG2ACE:A high-channel variant of GE DS200TCEBG1ACE,offering 16-channel AI,12-channel DI,and 8-channel DO for large-scale sensor networks in power plants.

GE DS200TCEBG1ACF:A low-temperature version with-40℃~+65℃operating range,designed for cold-climate applications like Arctic oil drilling and northern power plants.

GE DS200TCEBG1ACG:A high-power DO variant,with 1A per DO channel,for controlling heavy-duty actuators like large valves and motors in industrial processes.

GE DS200TCEBG1ACH:A communication expansion board paired with GE DS200TCEBG1ACE,adding 1 x Ethernet port(10/100Mbps)for integration with remote monitoring systems.

GE DS200TCEBG1ACI:A surge protection module for the board,providing protection against voltage surges(up to 6kV)in high-voltage environments like utility substations.

GE DS200TCEBG1ACJ:A calibration kit for GE DS200TCEBG1ACE,including a precision signal generator and GE’s proprietary software to verify analog input accuracy on-site.

GE DS200TCEBG1ACK:A terminal block extension kit,featuring 24 additional screw terminals for expanding sensor connectivity in distributed control applications.

GE DS200TCEBG1ACL:A cooling fan accessory for high-temperature environments(>65℃),such as steel mill control cabinets,to prevent board overheating and maintain performance.

GE DS200TCEBG1ACM:A redundancy module that pairs with GE DS200TCEBG1ACE to provide 1+1 hot standby,ensuring uninterrupted signal control in mission-critical systems like nuclear power plant safety loops.

Installation and Maintenance

Pre-installation preparation:Before installing GE DS200TCEBG1ACE,power off the GE Speedtronic Mark VI system cabinet to avoid electrical hazards.Confirm the cabinet’s 19-inch rack has 1U of available space and verify the Mark VI controller firmware is version 5.0 or higher(check GE’s compatibility matrix).Inspect the board for physical damage(e.g.,bent terminals,cracked housing)and ensure the power supply(18V~30V DC)matches the facility’s electrical system.For hazardous area installations,confirm the board’s ATEX certification aligns with the area classification(e.g.,Zone 2)and use flame-retardant wiring per IEC 60079-14.

Installation steps:Mount GE DS200TCEBG1ACE in the 19-inch rack using the provided screws(torque to 0.8 N·m)for secure attachment and proper heat dissipation.Connect the 24V DC power supply to the board’s power terminals,ensuring correct polarity(reverse polarity protection prevents damage,but incorrect wiring may cause temporary shutdown).Wire field sensors/actuators to the AI/DI/DO terminals—use twisted-pair cables for analog signals to reduce EMI,and crimp terminals for wire gauge>1.5mm².Connect the board to the Mark VI controller via the system’s backplane cable,then power on the cabinet and verify the power LED(green)illuminates;check signal status LEDs(yellow)to confirm sensor/actuator connectivity.

Maintenance recommendations:Conduct monthly visual inspections—check terminal connections for tightness,remove dust from the board with a soft brush,and verify LED indicators show normal operation.Every 3 months,run the board’s self-test function via the Mark VI software to detect hidden faults(e.g.,weak signal channels).Every 6 months,calibrate the analog inputs using the GE DS200TCEBG1ACJ kit:inject known signals(e.g.,12mA for 4-20mA AI)and confirm the Mark VI system receives values within±0.2%of full scale.In high-vibration environments(e.g.,turbine halls),tighten terminal screws every 4 months to prevent loosening.If the fault LED(red)illuminates,first check wiring and power supply—75%of faults are external;for internal issues,contact GE technical support(do not disassemble the board,as this voids the warranty).

Product Guarantee

GE provides a 24-month warranty for GE DS200TCEBG1ACE from the date of purchase,covering all manufacturing defects—including faulty signal conditioning circuits,terminal malfunctions,LED indicator failures,or compatibility issues with the Speedtronic Mark VI system(excluding damage from improper installation,overvoltage,exposure to conditions beyond specifications,or unauthorized modification).All boards are 100%genuine GE products,verified by serial number through GE’s global database to guarantee authenticity and compliance with industrial safety standards;non-genuine units are not covered.If the board malfunctions within the warranty period,GE offers free repair or replacement with expedited shipping to minimize downtime—critical for facilities where terminal control failure can disrupt process operations.Additionally,GE’s technical support team(specialized in Speedtronic systems)provides 24/7 remote assistance for installation,calibration,and troubleshooting.For mission-critical applications(e.g.,nuclear power plants),GE also offers extended warranty options(up to 36 months)and on-site service contracts,ensuring long-term reliability and peace of mind for users.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: