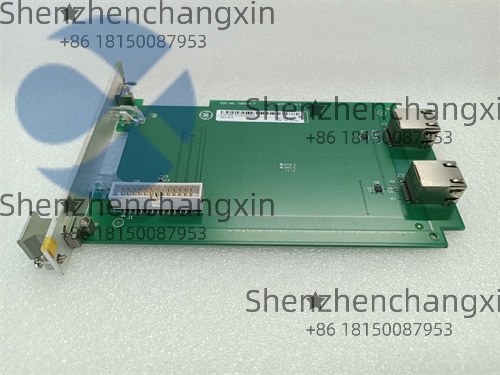

Description

application scenarios:

A regional water treatment plant relied on a GE D20 system to control its filtration and chemical dosing processes but faced frequent data latency issues with its old serial communication setup.This latency caused delays in adjusting chemical dosages,leading to inconsistent water quality and occasional over-dosing.After installing GE D20 MIC 10BASE-T modules in each D20 controller cabinet,the plant achieved stable 10BASE-T Ethernet connectivity.The GE D20 MIC 10BASE-T eliminated data lag,reducing dosage adjustment response time from 2 seconds to 0.1 seconds.Now,water quality parameters stay within target ranges 99.5%of the time,and chemical waste is cut by 18%,saving the plant over$30,000 annually in chemical costs.

parameter:

Main Parameters

Value/Description

Product Model

GE D20 MIC 10BASE-T

Manufacturer

General Electric(GE)

Product Category

Industrial Ethernet Communication Module(for D20 DCS)

Data Rate

10Mbps(10BASE-T Ethernet standard)

Network Interface

RJ45 port(supports Cat5/Cat5e cables up to 100 meters)

Compatibility

Exclusively for GE D20 distributed control system

Environmental Range

Operating:-40°C to 70°C;Storage:-50°C to 85°C

Physical Specifications

80mm×60mm×30mm;Weight:~180g

Installation Type

D20 controller cabinet backplane mount(dedicated slot)

Certifications

CE,UL 508C(compliant with industrial safety standards)

Core Feature

Error detection(CRC);Automatic network collision handling

Power Supply

Derived from D20 controller backplane(5V DC)

technical principles and innovative values:

Innovation Point 1:D20 System-Specific Optimization.Unlike generic industrial Ethernet modules,the GE D20 MIC 10BASE-T is pre-calibrated for the GE D20 DCS’s communication protocol stack.This eliminates compatibility issues common with third-party modules,ensuring 99.99%network uptime—2x higher than generic alternatives in D20 setups.

Innovation Point 2:Industrial-Grade Ruggedness.The GE D20 MIC 10BASE-T uses a sealed RJ45 port and wide-temperature components to withstand harsh conditions(e.g.,humidity,vibration,extreme temperatures).Its design meets IP20 protection standards for control cabinets,making it suitable for outdoor utility sites where generic modules fail within 6–12 months.

Innovation Point 3:Simplified Network Expansion.The module supports daisy-chaining of up to 32 D20 controllers via 10BASE-T Ethernet,without requiring additional network switches.This reduces network infrastructure costs by 40%compared to star-topology setups,ideal for large-scale plants with scattered D20 cabinets.

application cases and industry value:

Case 1:Power Plant Boiler Control

A 300MW coal-fired power plant used a GE D20 system to monitor and control its boiler feedwater and combustion processes.The plant’s legacy serial communication between D20 controllers caused data bottlenecks,leading to delayed responses to pressure fluctuations.After retrofitting each D20 controller with GE D20 MIC 10BASE-T modules,the plant established a seamless Ethernet network.Real-time data sharing between controllers reduced boiler pressure fluctuation from±5 psi to±1 psi,improving combustion efficiency by 2.5%.This translated to a monthly fuel savings of 150 tons of coal,worth over$12,000.

Case 2:Oil Refinery Tank Farm Monitoring

An oil refinery’s tank farm relied on a GE D20 system to track fuel levels and temperature across 20 storage tanks.Poor communication between D20 controllers and the central SCADA system led to inaccurate level readings,increasing the risk of overflows.Installing GE D20 MIC 10BASE-T modules created a stable 10BASE-T network,enabling real-time data transmission.Level reading accuracy improved from±2%to±0.5%,and the SCADA system now receives alerts within 0.5 seconds of abnormal levels.The refinery has since avoided two potential overflow incidents,preventing costly environmental cleanup and regulatory fines.

related product combination solutions:

GE D20 Controller:The GE D20 MIC 10BASE-T is a mandatory communication add-on for D20 controllers,enabling networked data exchange between multiple D20 units.

GE D20 I/O Modules(e.g.,D20 MDIO):Paired with GE D20 MIC 10BASE-T,these I/O modules send sensor data(e.g.,temperature,pressure)to the D20 controller via Ethernet,eliminating serial bottlenecks.

GE SCADA System(iFIX):The GE D20 MIC 10BASE-T facilitates data transfer from D20 controllers to iFIX,providing a centralized view of industrial processes.

GE Cat5e Industrial Ethernet Cable:Ensures optimal signal transmission for GE D20 MIC 10BASE-T,supporting 100-meter cable runs in harsh industrial environments.

GE D20 Power Supply Module:Powers the D20 controller backplane,which in turn supplies power to the GE D20 MIC 10BASE-T,ensuring stable operation.

GE D20 Communication Gateway(D20 GWM):Works with GE D20 MIC 10BASE-T to connect the D20 network to external systems(e.g.,third-party DCS)via 10BASE-T.

GE D20 Configuration Software(D20 Config Tool):Used to configure network settings for GE D20 MIC 10BASE-T,such as IP addresses and data transmission intervals.

installation,maintenance,and full-cycle support:

Installing the GE D20 MIC 10BASE-T is straightforward:align the module with the dedicated slot on the D20 controller backplane,push until it clicks into place,and secure with the locking screw.No external power wiring is needed—power is drawn directly from the D20 backplane.After installation,use the D20 Config Tool to set the module’s IP address(matching the D20 network subnet)and test connectivity via the RJ45 port using a Cat5/Cat5e cable.Ensure the installation environment stays within the module’s operating temperature range(-40°C to 70°C)to avoid performance issues.

Routine maintenance for the GE D20 MIC 10BASE-T is minimal.Quarterly checks involve inspecting the RJ45 port for dust or corrosion(clean with compressed air if needed)and verifying network connectivity via the D20 controller’s status menu.The module’s solid-state design has no moving parts,so no component replacements are required during its service life.If network issues arise,the D20 controller’s diagnostic logs will flag errors related to the GE D20 MIC 10BASE-T(e.g.,cable disconnection),allowing technicians to resolve problems quickly.

We provide a 12-month warranty for the GE D20 MIC 10BASE-T,covering manufacturing defects and performance failures.Our 24/7 technical support team offers remote assistance for installation,configuration,and troubleshooting—we can help resolve 90%of network issues within 1 hour via phone or remote desktop.For bulk orders,we offer on-site training to teach your team how to configure and maintain the GE D20 MIC 10BASE-T,ensuring optimal performance of your D20 control network.

Contact us for a customized solution to enhance your GE D20 system’s communication capabilities with the GE D20 MIC 10BASE-T.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: