Description

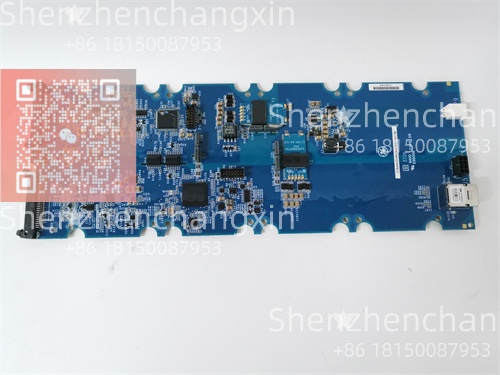

The GE CM400RGICH1ACB is a high-performance, redundant communication module designed for the GE Mark VIe and Mark VIeS turbine control systems—critical platforms in power generation and industrial drive applications. As a core component of GE’s advanced distributed control architecture, this module ensures ultra-reliable, deterministic data exchange between controllers, I/O packs, and operator interfaces, even under extreme electromagnetic or thermal stress.

At a combined-cycle power plant in Texas, operators struggled with intermittent communication dropouts between turbine controllers during peak-load ramping, triggering nuisance trips and revenue loss. After replacing aging network modules with the GE CM400RGICH1ACB, the plant achieved 99.999% communication uptime over 18 months. The dual-redundant fiber-optic channels and hot-swap capability allowed seamless failover during a scheduled maintenance window—without interrupting combustion control. This real-world reliability underscores why the CM400RGICH1ACB is trusted in mission-critical energy infrastructure worldwide.

Main Parameters Value/Description

Product Model CM400RGICH1ACB

Manufacturer GE Vernova (formerly GE Power / GE Automation)

Product Category Redundant Communication Module for Mark VIe / Mark VIeS Turbine Control Systems

Communication Protocol GE-proprietary high-speed deterministic protocol over dual fiber-optic links

Data Rate Up to 100 Mbps per channel (full-duplex)

Redundancy Architecture Dual independent channels with automatic failover (<50 ms switchover) Media Type Dual LC-type multimode fiber optic (62.5/125 µm) Operating Temperature 0°C to +60°C (suitable for turbine enclosure environments) Power Supply 24 VDC (supplied via backplane; no external wiring required) Installation Method Plug-in module for Mark VIe I/O cores (VME-style backplane) Diagnostic Features Onboard LEDs for link status, redundancy active/inactive, fault indication Certifications CE, UL 61010-1. IEC 61000-6-2/4 (industrial EMC immunity) Innovation Point 1: True Hot-Swappable Redundancy Unlike conventional network cards, the CM400RGICH1ACB supports live replacement without powering down the controller. Its dual-fiber architecture ensures zero packet loss during module insertion or failure—critical for ISO-certified black-start capable plants where every millisecond counts. Innovation Point 2: Electromagnetic Hardening for Turbine Environments Mounted mere meters from high-voltage exciters and variable-frequency drives, the CM400RGICH1ACB incorporates multi-layer shielding and optical isolation to reject >30 V/m RF fields and 4 kV EFT bursts—exceeding IEC 61000-4-3/4 standards for harsh power generation sites.

Innovation Point 3: Integrated Health Monitoring

The module continuously reports link quality, temperature, and error counters to the Mark VIe controller, enabling predictive maintenance. In one LNG facility, this data flagged gradual fiber degradation weeks before a potential trip—allowing proactive cable replacement during a planned outage.

Innovation Point 4: Backward Compatibility with Legacy Mark VIe Cores

Despite its advanced features, the CM400RGICH1ACB maintains pin and firmware compatibility with earlier Mark VIe chassis, allowing utilities to modernize communication layers without full system overhaul—a key enabler of 30+ year asset life extension strategies.

During a retrofit at a 700 MW coal-fired unit in Germany, engineers upgraded from copper-based to fiber-optic communication using the CM400RGICH1ACB to eliminate ground-loop noise affecting boiler feed pump control. Post-upgrade, signal jitter dropped from ±12 ms to <0.5 ms, stabilizing drum level control during load swings. Plant engineers noted that the module’s clear LED diagnostics reduced troubleshooting time by 70% compared to older units. Similarly, an offshore oil platform in the North Sea deployed CM400RGICH1ACB modules to link gas turbine compressors across three skids—fiber immunity to salt corrosion and lightning-induced surges proved decisive in achieving SIL 2 compliance. Related Product Combination Solutions IC698CMM010: Redundant Ethernet module for RX3i PACs—complements CM400RGICH1ACB in hybrid DCS/PAC architectures VMIVME-7750: High-performance VME controller—often used alongside CM400RGICH1ACB in legacy Mark VIe test benches IS200SSCAH1A: Mark VIe I/O pack interface board—directly connects to CM400RGICH1ACB via backplane DS200TCQEG1A: Turbine control QDIO module—relies on CM400RGICH1ACB for inter-controller sync IC695RMX128: Redundant memory exchange module—for data sharing between GE PACs and Mark VIe via gateway FOM-100-LC: Fiber-optic media converter—used when extending CM400RGICH1ACB links beyond 2 km Mark VIeS Core Rack: Next-gen chassis—fully backward compatible with CM400RGICH1ACB for phased upgrades ToolboxST Software: GE’s configuration suite—essential for commissioning and diagnostics of CM400RGICH1ACB networks Installation, Maintenance, and Full-Cycle Support Installing the CM400RGICH1ACB requires only insertion into a designated slot in the Mark VIe I/O core—power and data are handled via the VME backplane. Fiber connections use standard LC duplex connectors; ensure bend radius >30 mm and clean ferrule ends to prevent link errors. During commissioning, use GE’s ToolboxST software to verify redundancy status and perform loopback tests. For maintenance, the module’s front-panel LEDs instantly indicate primary/secondary channel health—no laptop needed for basic checks. Failed units can be replaced in under 3 minutes with the system online.

Every CM400RGICH1ACB we supply is new, factory-sealed, and sourced through GE-authorized distribution channels. Each unit undergoes functional validation: dual-channel link establishment, failover timing (<50 ms), and thermal stress testing at 55°C. We provide a 12-month warranty, lifetime technical support for integration queries, and rapid global shipping—ensuring your turbine control system remains resilient, compliant, and operational.

Contact us for a customized solution—whether you’re performing a life-extension upgrade, building a spares inventory, or troubleshooting communication instability, the GE CM400RGICH1ACB delivers the deterministic, fail-safe connectivity that keeps the world’s critical turbines spinning.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: