Description

Product Overview

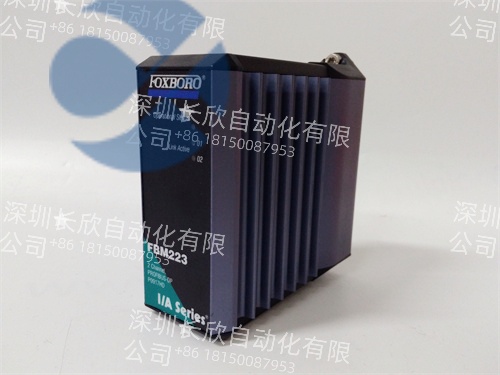

The FOXBORO FBM223 P0917HD represents a sophisticated programmable logic controller(PLC)module specifically designed for industrial automation and process control applications.As part of FOXBORO’s comprehensive product portfolio,thisFBM223 P0917HDmodule serves as a critical component in distributed control systems(DCS)and industrial automation networks.TheFOXBORO FBM223 P0917HDis engineered to provide reliable monitoring and control capabilities for various industrial processes,making it an essential element in modern manufacturing and process industries

.

This advanced PLC module features a compact design that leverages microcontroller technology,enabling efficient integration into space-constrained industrial environments.TheFOXBORO FBM223 P0917HDoffers powerful logical processing capabilities combined with numerical computation and communication interface support,allowing it to handle complex automation requirements across diverse industrial applications.With its robust architecture and reliable performance,theFBM223 P0917HDensures continuous operation in demanding industrial settings where process reliability and uptime are critical considerations

.

TheFOXBORO FBM223 P0917HDsupports multiple programming languages and communication protocols,including PROFIBUS DP,enabling seamless integration with various field devices and higher-level control systems.Its modular design facilitates easy maintenance and replacement,while comprehensive diagnostic capabilities provide real-time monitoring of system health and performance.The module’s versatility makes it suitable for applications ranging from simple sequential control to complex process automation tasks,offering plant operators the flexibility to implement customized control strategies while maintaining system reliability and safety

.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FBM223 P0917HD

Manufacturer

FOXBORO

Product Type

Programmable Logic Controller(PLC)Module

Processor Architecture

32-bit Microcontroller

Memory Configuration

System Program Memory and User Program Memory

Input/Output Interfaces

Digital I/O,Analog I/O,Communication Interfaces

Communication Protocols

PROFIBUS DP,Ethernet,Serial Communication

Programming Languages

Ladder Logic,Function Block Diagram,Structured Text

Operating Temperature

-20°C to+60°C

Power Supply

24V DC

Power Consumption

<15W

Mounting Method

DIN Rail Mounting

Dimensions

100mm×50mm×25mm(approximate)

Weight

0.5kg(approximate)

Certifications

CE,UL,IEC Standards Compliance

Environmental Rating

IP20(standard),IP65(optional)

Memory Capacity

2MB Flash,1MB RAM

Communication Speed

Up to 12Mbps(PROFIBUS DP)

I/O Points

Configurable up to 1024 points

Scan Time

<1ms for 1K instructions

Diagnostic Functions

Comprehensive self-diagnostics and fault detection

Main Features and Advantages

Advanced processing capabilities:TheFOXBORO FBM223 P0917HDincorporates a high-performance 32-bit microcontroller that delivers exceptional processing power for complex automation tasks.This processing capability enables the module to handle sophisticated control algorithms,mathematical computations,and data processing functions simultaneously.TheFBM223 P0917HD’s efficient instruction set and optimized architecture ensure rapid scan times,making it suitable for applications requiring fast response times and precise control.The module’s processing power allows it to manage multiple control loops and communication tasks concurrently,providing comprehensive control functionality in a single compact unit

.

Flexible communication options:One of the key strengths of theFOXBORO FBM223 P0917HDis its extensive communication capabilities.The module supports multiple industrial communication protocols including PROFIBUS DP,Ethernet,and serial communication interfaces.This flexibility enables seamless integration with various field devices,sensors,actuators,and higher-level control systems.TheFBM223 P0917HD’s communication interfaces facilitate real-time data exchange between different system components,enabling coordinated control actions and comprehensive process monitoring.The module’s support for standard industrial protocols ensures compatibility with existing automation infrastructure and simplifies system integration efforts

.

Comprehensive diagnostic and monitoring:TheFOXBORO FBM223 P0917HDfeatures advanced diagnostic capabilities that continuously monitor system health and performance.The module includes comprehensive self-diagnostic functions that check internal components,memory integrity,and communication interfaces.External diagnostics extend to field devices and wiring,detecting issues such as wire breaks,short circuits,and sensor failures.These diagnostic features enable predictive maintenance and reduce mean time to repair,contributing to overall system availability and reliability.TheFBM223 P0917HDprovides detailed diagnostic information through multiple channels including local indicators,system logs,and network communications,allowing operators to quickly identify and address potential issues

.

Robust and reliable design:TheFOXBORO FBM223 P0917HDis engineered for reliable operation in demanding industrial environments.The module features robust construction with protection against electrical noise,vibration,and temperature variations.Its compact design and DIN rail mounting facilitate easy installation and maintenance,while the modular architecture allows for flexible system configuration and expansion.TheFBM223 P0917HD’s reliability is further enhanced by its comprehensive fault detection and recovery mechanisms,ensuring continuous operation even under challenging conditions.The module’s design incorporates redundancy options and fail-safe features that maintain system integrity during component failures or power disruptions

.

Application Field

TheFOXBORO FBM223 P0917HDfinds extensive application in industrial automation systems across various sectors.In manufacturing facilities,theFBM223 P0917HDserves as a core component in production line control systems,managing equipment sequencing,process synchronization,and quality control functions.The module’s powerful processing capabilities and flexible I/O configuration make it suitable for controlling complex machinery,robotic systems,and material handling equipment.In automotive manufacturing,theFOXBORO FBM223 P0917HDensures precise control of assembly processes,welding operations,and paint systems,contributing to improved production efficiency and product quality

.

Chemical and petrochemical plants utilize theFOXBORO FBM223 P0917HDfor process control applications involving hazardous materials and high-pressure processes.The module manages critical process parameters such as temperature,pressure,flow rates,and level control in reactors,distillation columns,and storage facilities.TheFBM223 P0917HD’s reliability and diagnostic capabilities make it suitable for safety instrumented functions(SIFs)that protect personnel,equipment,and the environment from process hazards.In these applications,the module’s ability to handle complex control logic and rapid response requirements ensures safe and efficient process operation

.

Water and wastewater treatment facilities employ theFOXBORO FBM223 P0917HDfor process automation and monitoring.The module controls pumping stations,chemical dosing systems,filtration processes,and disinfection systems.Its communication capabilities enable integration with SCADA systems for centralized monitoring and control of distributed treatment facilities.TheFBM223 P0917HD’s robust design and environmental protection features make it suitable for installation in harsh environments such as pump stations and treatment plants,where reliable operation is essential for maintaining water quality and regulatory compliance

.

Power generation and energy management systems benefit from theFOXBORO FBM223 P0917HD’s capabilities in monitoring and controlling critical equipment.The module manages turbine protection systems,boiler control,and auxiliary equipment monitoring in power plants.Its communication interfaces facilitate data exchange with energy management systems for optimizing energy consumption and reducing operational costs.TheFBM223 P0917HD’s diagnostic features and reliability ensure continuous operation of critical power generation equipment,contributing to grid stability and energy security

.

Related Products

FOXBORO FBM201:Basic digital I/O module for simple control applications

FOXBORO FBM202:Enhanced digital I/O module with increased point density

FOXBORO FBM203:Analog input module for process signal acquisition

FOXBORO FBM204:Analog output module for control signal generation

FOXBORO FBM205:High-speed counter module for motion control applications

FOXBORO FBM206:Communication module for network integration

FOXBORO FBM207:Temperature input module for thermocouple and RTD signals

FOXBORO FBM211:Position control module for servo and stepper motor applications

FOXBORO FBM217:Safety relay module for emergency stop functions

FOXBORO FBM242:Communication gateway module for protocol conversion

Installation and Maintenance

Pre-installation preparation:Before installing theFOXBORO FBM223 P0917HD,ensure that the installation environment meets the specified temperature and humidity requirements.Verify that the power supply provides stable 24V DC power within the acceptable tolerance range and that all necessary mounting hardware and cables are available.Check the compatibility with existing system components and communication networks,and review the manufacturer’s installation guidelines to ensure proper installation procedures are followed.Ensure adequate clearance around the module for proper ventilation and heat dissipation,with minimum spacing as recommended in the installation manual

.

Maintenance recommendations:Regular maintenance of theFOXBORO FBM223 P0917HDshould include periodic review of system diagnostics and event logs to identify potential issues before they affect system performance.Verify that all module connections remain secure and free from corrosion,and check for any signs of physical damage or environmental contamination.Keep the firmware updated to the latest version to ensure optimal performance and access to the latest features.Implement a regular testing schedule for control functions to verify proper operation of the entire control loop,including field devices and wiring.Maintain comprehensive documentation of all configuration changes and maintenance activities,and ensure that spare parts are available for critical components to minimize downtime in case of failures

.

Product Guarantee

We stand behind the quality and performance of theFOXBORO FBM223 P0917HDwith comprehensive product support and technical expertise.Our commitment includes genuine FOXBORO components with full manufacturer warranty coverage,ensuring that everyFBM223 P0917HDmodule meets original equipment specifications and performance standards.Technical support is available from experienced automation professionals familiar with FOXBORO products and industrial control applications.We ensure timely delivery of products and provide detailed documentation to support proper installation,configuration,and operation.Our quality assurance process includes thorough testing and verification procedures to guarantee that everyFOXBORO FBM223 P0917HDdelivers reliable performance in your control system,backed by our commitment to customer satisfaction and long-term support

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: