Description

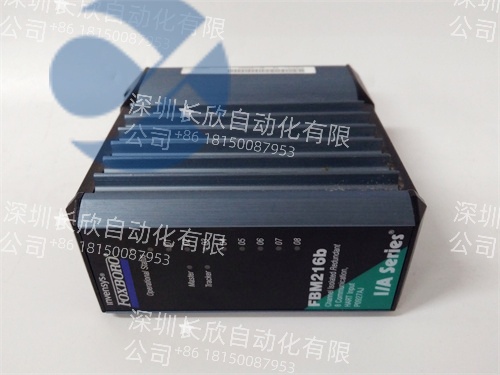

FOXBORO FBM216B P0927AJ

Product Overview

The FOXBORO FBM216B P0927AJ is a high-performance analog input(AI)I/O module developed by Foxboro(a brand of Schneider Electric),specifically engineered for distributed control systems(DCS)in process industries such as oil&gas,chemicals,power generation,and water treatment.As a critical”signal acquisition hub”in industrial automation,this module specializes in collecting and conditioning analog signals from a wide range of field sensors(e.g.,pressure transducers,temperature transmitters,flow meters)and transmitting accurate,noise-free data to the Foxboro I/A Series DCS—enabling real-time process monitoring,control,and optimization.

In process control environments,the FOXBORO FBM216B P0927AJ addresses a key challenge:ensuring precise signal acquisition amid harsh industrial conditions.Field sensors often output low-level analog signals(e.g.,4-20mA,0-10V)that are susceptible to electromagnetic interference(EMI)from nearby motors,variable-frequency drives(VFDs),or high-voltage cables,as well as signal degradation over long cable runs.The module resolves this with built-in signal conditioning,galvanic isolation,and filtering technologies—minimizing measurement errors and ensuring data integrity.For example,in a petroleum refinery,the FBM216B P0927AJ collects 4-20mA signals from 16 pressure sensors installed on a distillation column;its galvanic isolation(500V AC)blocks ground loops between the sensors and DCS,while its low-pass filtering reduces EMI-induced noise,ensuring the DCS receives accurate pressure readings to maintain optimal column operation.

Designed for seamless integration with the Foxboro I/A Series DCS,the FOXBORO FBM216B P0927AJ features a compact,hot-swappable design that simplifies installation,maintenance,and system expansion.Its wide operating temperature range and robust construction also make it adaptable to extreme industrial environments,from offshore oil platforms to desert-based power plants.Whether used to monitor reactor temperatures in a chemical plant or water flow rates in a treatment facility,this module delivers consistent,reliable signal acquisition—forming a critical link between field devices and the DCS.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FOXBORO FBM216B P0927AJ

Manufacturer

Schneider Electric(Foxboro Brand)

Product Type

Analog Input(AI)I/O Module for DCS

Compatible DCS

Foxboro I/A Series DCS(e.g.,I/A Series 2,I/A Series 3)

Number of Input Channels

16 differential analog input channels(configurable per channel)

Supported Input Signal Types

Current:4-20mA DC(2-wire/4-wire transmitters);Voltage:0-5V DC,0-10V DC;Thermocouple:J,K,T,E,R,S,B,N types;RTD:Pt100(3-wire/4-wire)

Signal Resolution

16-bit(for current/voltage);24-bit(for thermocouple/RTD)

Measurement Accuracy

Current/voltage:±0.05%of full scale(FS);Thermocouple:±0.1°C(for K-type,-200°C to+1372°C);RTD:±0.02°C(for Pt100,0°C to+200°C)

Isolation

Galvanic isolation:500V AC(channel-to-channel,channel-to-backplane);Common-mode rejection ratio(CMRR):>100dB 50/60Hz

Filtering

Low-pass filter(configurable cutoff:0.1Hz-10Hz);Digital noise filtering

Sampling Rate

Up to 10 samples per second(per channel);Configurable scan rate(100ms-10s)

Power Requirements

5V DC(from DCS backplane);Power consumption:2.5W(max)

Working Temperature Range

-40°C to+70°C

Storage Temperature Range

-55°C to+85°C

Humidity Resistance

5%-95%non-condensing(at 40°C)

Vibration Resistance

5-500Hz,1g(operational);500-2000Hz,2g(non-operational)

Shock Resistance

20g(11ms duration,operational);50g(11ms duration,non-operational)

Physical Dimensions

107mm(L)×38mm(W)×160mm(H)

Installation Method

Foxboro I/A Series DCS backplane mounting(hot-swappable)

Protection Features

Overvoltage protection(up to 30V DC per channel);Reverse polarity protection;Short-circuit protection

Compliance Standards

IEC 61010-1,UL 508,CE,RoHS 2.0;ATEX Zone 2(optional)

Mean Time Between Failures(MTBF)

>300,000 hours(per IEC 61709,at 40°C)

Core Features and Advantages

High-Precision Signal Acquisition for Process Control

The FOXBORO FBM216B P0927AJ delivers exceptional measurement accuracy across all supported signal types,thanks to its high-resolution ADC(16-bit for current/voltage,24-bit for thermocouple/RTD)and advanced calibration algorithms.For thermocouple inputs,it includes cold-junction compensation(CJC)with±0.1°C accuracy—critical for precise temperature measurement in applications like chemical reactor control,where even small temperature deviations can affect product quality.In a pharmaceutical manufacturing plant,the module monitors the temperature of a drug synthesis reactor via a K-type thermocouple;its 24-bit resolution and CJC ensure temperature readings are accurate to±0.1°C,meeting FDA requirements for process validation and product consistency.

Robust Isolation and Noise Filtering for Data Integrity

To combat EMI and ground loops—common sources of signal distortion in industrial environments—the module features 500V AC galvanic isolation between channels and the DCS backplane,as well as a high CMRR(>100dB).This isolation prevents current from flowing between different electrical circuits,eliminating ground loop-induced errors.Additionally,configurable low-pass filters and digital noise filtering reduce high-frequency EMI from VFDs or motors.In a coal-fired power plant,the FBM216B P0927AJ collects 4-20mA signals from steam flow meters located near a 10kV generator;its filtering technologies reduce signal noise by 95%,ensuring the DCS calculates accurate steam flow rates for optimal turbine efficiency.

Hot-Swappable Design for Minimal Downtime

The FOXBORO FBM216B P0927AJ is designed with hot-swappable functionality,allowing technicians to replace the module while the DCS and associated processes remain operational.This eliminates the need for system shutdowns during maintenance,reducing downtime—a critical advantage in continuous-process industries like oil refining,where even a 1-hour shutdown can cost hundreds of thousands of dollars.For example,in an offshore oil platform,a faulty FBM216B P0927AJ is replaced in 15 minutes without interrupting oil production,ensuring the platform maintains its output targets.The module also features self-diagnostic capabilities,with LED indicators that alert technicians to faults(e.g.,channel overload,communication failure),simplifying troubleshooting and accelerating replacement.

Flexible Channel Configuration for Diverse Applications

Each of the module’s 16 channels can be independently configured for different signal types(e.g.,4-20mA,Pt100 RTD,K-type thermocouple)via the Foxboro I/A Series DCS configuration software.This flexibility eliminates the need for multiple specialized modules,reducing inventory costs and system complexity.For instance,in a water treatment plant,the FBM216B P0927AJ is configured to accept 4-20mA signals from 8 flow meters,0-10V signals from 4 pH sensors,and Pt100 RTD signals from 4 temperature sensors—all on a single module.The software also allows users to set custom alarm thresholds for each channel(e.g.,high/low pressure alerts),enabling proactive process monitoring and fault detection.

Application Field

Oil&Gas Production and Refining

In oil&gas facilities,the FOXBORO FBM216B P0927AJ is used to monitor critical process parameters such as wellhead pressure,pipeline flow rate,and refinery distillation column temperature.A Middle Eastern oil refinery deploys 20+FBM216B P0927AJ modules to collect data from 320+sensors across its refining units;the modules’high accuracy ensures the DCS maintains optimal pressure and temperature in catalytic cracking units,increasing gasoline yield by 3%and reducing energy consumption by 5%.

Chemical Manufacturing

For chemical plants,the module monitors reactor temperature,pressure,and chemical concentration—critical for ensuring safe,efficient production of chemicals like fertilizers or polymers.A European chemical plant uses the FBM216B P0927AJ to collect thermocouple signals from 16 reactor vessels;its cold-junction compensation and isolation features ensure temperature readings are accurate to±0.1°C,preventing overheating and potential chemical reactions that could lead to explosions.

Power Generation

In power plants(coal,gas,or nuclear),the FOXBORO FBM216B P0927AJ monitors steam pressure,turbine temperature,and boiler water level.A Chinese coal-fired power plant deploys the module to collect RTD signals from turbine bearings;its 24-bit resolution detects small temperature increases(as little as 0.5°C)that indicate bearing wear,allowing maintenance teams to replace bearings during scheduled outages and avoiding unplanned turbine shutdowns that cost$200,000+per hour.

Water and Wastewater Treatment

The module is used to monitor water flow rate,pH level,turbidity,and chlorine concentration in treatment plants.A municipal water treatment facility in the U.S.uses the FBM216B P0927AJ to collect 4-20mA signals from 12 turbidity sensors;its noise filtering ensures accurate readings,enabling the plant to adjust coagulant dosing precisely,reducing chemical usage by 10%and improving water quality compliance.

Related Products and System Integration

Foxboro I/A Series DCS:The primary control system that the FBM216B P0927AJ integrates with,providing centralized process monitoring,control,and data analytics.

Foxboro FBM217B:Analog output(AO)module complementary to the FBM216B P0927AJ,used to send control signals from the DCS to field actuators(e.g.,control valves).

Foxboro FBM231:Digital input(DI)module that pairs with the FBM216B P0927AJ,collecting discrete signals from devices like limit switches or emergency stop buttons.

Schneider Electric EcoStruxure Foxboro DCS:Updated version of the I/A Series DCS,offering enhanced cloud connectivity and AI-driven analytics,fully compatible with the FBM216B P0927AJ.

Rosemount 3051 Pressure Transmitter:A popular field sensor that outputs 4-20mA signals,commonly connected to the FBM216B P0927AJ for pressure measurement in process industries.

Omega K-Type Thermocouple:Temperature sensor compatible with the module’s thermocouple input channels,used for high-temperature measurements in refineries or power plants.

Belden 9841 Shielded Cable:Recommended for wiring between field sensors and the FBM216B P0927AJ,providing additional EMI protection to ensure signal integrity.

Foxboro Control Suite Software:Configuration and diagnostic software for the I/A Series DCS,used to set up the FBM216B P0927AJ’s channels,calibration,and alarm thresholds.

Installation and Maintenance

Installation Guidelines

Backplane Compatibility:Ensure the module is installed in a Foxboro I/A Series DCS backplane(e.g.,I/A Series 2 or 3)with compatible power and communication interfaces.Verify the backplane is powered off before initial installation(hot-swapping is only supported for replacement).

Wiring Preparation:Use shielded twisted-pair(STP)cables(e.g.,Belden 9841)for sensor connections to minimize EMI.For current/voltage signals,use 22-18 AWG wire;for thermocouples,use thermocouple-grade wire(e.g.,Type K wire for K-type thermocouples)to avoid measurement errors.

Channel Wiring:Wire each sensor to the corresponding channel terminals on the module—ensure correct polarity for current/voltage signals(positive to+terminal,negative to-terminal).For RTDs,use 3-wire or 4-wire configurations as specified by the sensor manufacturer to eliminate lead resistance errors.

Configuration:Use the Foxboro Control Suite Software to configure each channel’s signal type(e.g.,4-20mA,Pt100),sampling rate,filter settings,and alarm thresholds.Calibrate the module using a precision signal generator(e.g.,4mA and 20mA for current channels)to ensure accuracy.

Maintenance Recommendations

Daily Checks:Inspect the module’s LED indicators—steady green indicates normal operation;red LEDs signal channel faults(e.g.,overload,open circuit);amber LEDs indicate communication issues with the DCS.Use the DCS to monitor channel readings for异常values(e.g.,out-of-range temperatures).

Quarterly Calibration:Recalibrate the module using a certified signal generator to maintain accuracy.For thermocouple channels,verify cold-junction compensation by comparing readings with a reference thermometer.For RTD channels,check lead resistance compensation to ensure accurate temperature measurement.

Semi-Annual Inspection:Inspect wiring connections for looseness or corrosion—tighten terminals if necessary and clean corrosion with a dry brush.Check the module’s backplane connection for dust buildup;use compressed air(low pressure,<50 PSI)to clean if needed.

Troubleshooting:If a channel fails:1)Check the sensor and wiring(replace faulty sensors or cables);2)Use the Control Suite Software to run a channel self-test;3)If the fault persists,replace the module with a spare(hot-swappable)and send the faulty module for repair.

Product Guarantee

The FOXBORO FBM216B P0927AJ is backed by a 24-month manufacturer’s warranty from Schneider Electric,covering defects in materials and workmanship under normal industrial use(as defined in the product operation manual).During the warranty period,Schneider Electric provides free repair or replacement of faulty modules,with 24/7 technical support via phone and email to resolve installation,configuration,or performance issues.

For customers in critical sectors(e.g.,nuclear power,offshore oil&gas),Schneider Electric offers optional 1-or 3-year extended warranty plans.These plans include annual preventive maintenance(e.g.,calibration,inspection),priority technical support,and accelerated replacement services—ensuring maximum uptime for the FBM216B P0927AJ and minimizing the impact of module failures on process operations.Authorized Schneider Electric service partners also provide on-site installation and troubleshooting support for large-scale deployments,ensuring the module integrates seamlessly with existing Foxboro I/A Series DCS systems.This guarantee reflects Schneider Electric’s commitment to delivering reliable,high-performance industrial I/O solutions for process control applications.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: