Description

Application Scenarios:

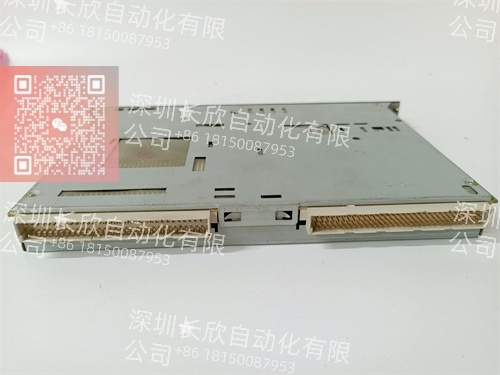

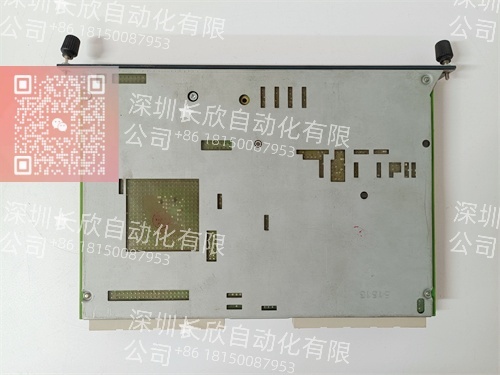

At an automotive parts manufacturer deploying collaborative robot cells, engineers needed a scalable way to monitor safety gates and E-stops without adding bulky external safety relays. By installing the FB201 directly into the KEBA KeMotion controller rack, they created a fully integrated safety architecture where safety logic executed within the same runtime as motion control—reducing response time to <20 ms and eliminating wiring between separate safety PLCs. Over 18 months, the facility reported zero safety-related downtime attributable to I/O faults. This real-world success underscores how the FB201 simplifies machine design while elevating safety performance beyond traditional relay-based approaches. Main Parameters Value/Description Product Model FB201 Manufacturer KEBA Group (Austria) Product Category Safety Digital Input Module (Modular Terminal) Safety Certification SIL 3 (IEC 62061), PL e / Category 4 (EN ISO 13849-1) Input Channels 8 (dual-channel, force-guided contact evaluation) Input Voltage 24 VDC (nominal), 15–30 VDC operating range Input Current ~3 mA per channel at 24 VDC Wiring Method Screw terminals (max AWG 16), removable for easy maintenance Diagnostic Coverage >99% (includes wire break, short-circuit, cross-wire detection)

Communication Interface Integrated via KEBA backplane bus (no external cabling to CPU)

Operating Temperature 0°C to +55°C

Protection Rating IP20 (for installation in control cabinets)

Mounting DIN rail (TS 35/7.5 or 15 mm)

Redundancy Support Full 1oo2 evaluation per channel with automatic fault signaling

Technical Principles and Innovative Values:

• Integrated Safety Runtime: Unlike standalone safety relays, the FB201 operates within KEBA’s certified safety PLC environment—enabling complex safety logic (e.g., muting, bypass sequences) directly in the controller, reducing hardware footprint and validation effort.

• Force-Guided Contact Monitoring: Each input on the FB201 uses dual independent circuits with mechanical linkage verification, ensuring that welded contacts cannot falsely indicate a “safe” state—a requirement for PL e compliance.

• Zero External Wiring to CPU: As part of KEBA’s modular I/O system, the FB201 communicates with the safety controller over a secure internal backplane, eliminating Ethernet/IP or fieldbus configuration and reducing points of failure.

• Predictive Diagnostics: The FB201 continuously monitors wiring integrity and reports degradation trends via KEBA’s engineering tools, enabling maintenance before a fault causes a shutdown—key for high-availability production lines.

Application Cases and Industry Value:

In a European packaging line for pharmaceutical blister machines, the FB201 replaced a legacy safety relay panel that required weekly manual checks. With automatic self-diagnostics and remote status visibility through the KEBA KeTop HMI, maintenance shifted to condition-based scheduling, cutting inspection labor by 70%. In another case, a palletizing robot integrator used four FB201 modules to monitor 32 safety zones across three workcells. The unified safety architecture passed TÜV audit on first submission, accelerating time-to-market by six weeks. Users consistently praise the FB201 for its “plug-and-certify” simplicity in CE-marked machinery.

Related Product Combination Solutions:

• KeMotion K300/K500: KEBA’s motion controllers—native hosts for FB201 in robotic and CNC applications.

• FB202: Complementary 4-channel safety output module for driving contactors or safety drives.

• FB101: Standard (non-safety) 16-channel digital input module—ideal for non-critical signals alongside FB201.

• KeConnect Safety PLC: Software-configurable safety runtime that executes logic from FB201 inputs.

• KeTop T200/T300: KEBA HMIs that display real-time FB201 diagnostic status and safety reset functions.

• FB301: Analog safety input module for pressure or temperature safety thresholds.

• KEBA Safety Configurator: Engineering tool for validating FB201-based safety circuits and generating compliance reports.

• KEMRO K3: Compact KEBA controller for small machines—supports FB201 in space-constrained cabinets.

Installation, Maintenance, and Full-Cycle Support:

Installing the FB201 requires only DIN-rail mounting and connection to the KEBA backplane—no network setup or IP addressing. Field devices wire directly to labeled screw terminals, with clear markings for NC/NO and dual-channel pairs. During commissioning, the KEBA Safety Configurator auto-detects the FB201. validates wiring topology, and generates a safety validation report compliant with ISO 13849. For maintenance, LED indicators show per-channel status (OK/fault), and detailed diagnostics are accessible via KeTop or remote service tools.

We rigorously test every FB201 unit through 48-hour thermal cycling, full-channel functional validation under voltage extremes, insulation resistance testing (>100 MΩ), and simulated fault injection (e.g., shorted wires, open circuits). Each module includes a certificate of conformity and batch traceability. Our support team provides pre-certified safety function blocks, wiring diagrams, and TÜV-ready documentation packages. All units come with a 12-month warranty and direct access to KEBA-certified application engineers.

Contact us for a customized solution—whether you’re building a new CE-compliant machine or upgrading an existing safety system, we ensure your FB201 deployment delivers certified reliability, simplified integration, and future-proof scalability.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: