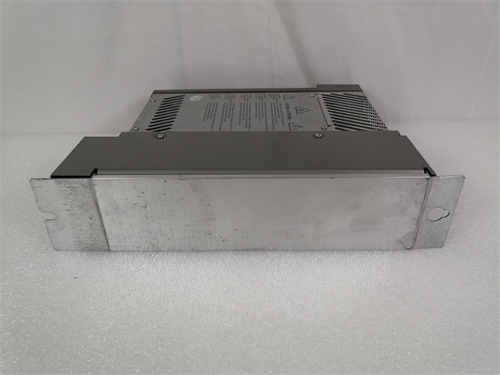

Description

Application Scenarios

In a high-speed food packaging line, multiple servo axes must work in perfect synchrony to accurately pick, place, fill, and seal products at rates exceeding 200 units per minute. The central PacDrive controller calculates the complex motion profiles. The ELAU MC-41110400 drive module acts as the powerful muscle behind a specific servo axis, such as the one controlling the intermittent motion of a sealing jaw. It receives high-speed setpoint commands and feedback, precisely regulating the current to the servo motor to achieve the exact torque, speed, and position required. Its modular design allows it to be plugged into a multi-axis rack right next to the controller, minimizing cabling and creating a compact, high-performance control cabinet. This integration enables the machine builder to achieve the rapid, coordinated movements essential for maximizing throughput and ensuring package integrity.

Parameter

Annotation: The part number MC-41110400 is the unique identifier. “MC” strongly suggests “Motion Control” or “Module Controller.” It is a critical component within a larger, integrated PacDrive system and is not a standalone drive. Its exact electrical specifications (voltage, current rating) are defined by this part number but require the system manuals for full details.

Technical Principles and Innovative Values

The ELAU MC-41110400 embodies the principles of centralized, software-centric motion control within a modular hardware architecture.

Innovation Point 1: Centralized Intelligence with Distributed Power. In the PacDrive architecture, the complex motion planning and coordination for all axes are handled by a single, powerful master controller (like a C400). The MC-41110400 modules are dedicated to executing the high-speed, high-fidelity current (torque) control for their respective motors. This separation allows for optimal resource allocation: the master handles complex algorithms and synchronization, while the drive modules focus on precise, rapid power delivery, resulting in superior dynamic performance and simplified multi-axis coordination.

Innovation Point 2: Modular and Scalable System Design. The module is designed for a rack-based system. Machine builders can start with a few axes and add more by simply plugging additional MC-41110400 modules into the rack, alongside shared power supply and controller modules. This modularity drastically reduces cabinet size, wiring complexity, and engineering time compared to a cabinet full of individual stand-alone drives. It creates a clean, integrated “automation core.”

Innovation Point 3: Tight Software Integration for Simplified Engineering. The entire system, including the MC-41110400. is configured and programmed within a single, unified software environment (e.g., Automation Studio). The engineer defines the machine’s kinematics and logic, and the software automatically handles the low-level configuration of the drive modules. This integration reduces commissioning time, eliminates compatibility issues, and allows for advanced features like automatic tuning and centralized diagnostics across all axes.

Application Cases and Industry Value

Case Study: Revolutionizing a Digital Printing Press

A manufacturer of high-end digital label printing presses needed to achieve micron-level registration accuracy between printing heads and the web at speeds over 100 meters per minute. Their previous system, using discrete drives from different vendors, suffered from synchronization jitter. They adopted the ELAU PacDrive system with MC-41110400 drive modules. Each critical axis—web tension, print cylinder, and cutter—was driven by its own MC-41110400. The centralized PacDrive controller performed real-time electronic gearing and cam profiling. The result was a dramatic reduction in registration error, enabling the use of higher-resolution printheads. The modularity also allowed the builder to offer customers a scalable platform; adding a new print station simply meant adding another controller module and MC-41110400 drive to the existing rack. This flexibility became a key market differentiator, shortening their custom machine development time by 25%.

Case Study: High-Speed Pick-and-Place for Electronics

An automation integrator building a system to populate circuit boards needed a robot capable of placing surface-mount devices (SMDs) with extreme speed and precision. The solution used a 4-axis SCARA robot where each joint was driven by a dedicated MC-41110400 module. The direct, high-speed communication between the controller and the drives over the system’s deterministic backplane allowed for incredibly fast control loop updates. This enabled the implementation of advanced motion profiles that minimized vibration at the end-of-arm tool, allowing the robot to “swoop” into place at maximum speed without overshoot. The cycle time was reduced by 15% compared to their previous solution, directly increasing the customer’s production capacity. The integrated diagnostics also provided predictive maintenance alerts on motor and drive performance, reducing unplanned downtime.

Related Product Combination Solutions

ELAU C400 Controller (e.g., specific model number): The central motion and logic controller for the PacDrive system. The MC-41110400 drive modules receive their motion commands from this master controller.

ELAU PS-4xxxxx Power Supply Module: A system power supply module that provides the shared DC bus voltage to the rack, which is then used by all the MC-41110400 drive modules in that rack.

ELAU SM-xxxxxx Servo Motor: A matching ELAU servo motor designed to be optimally paired with the MC-41110400 drive for peak performance, often with a specific feedback system.

ELAU I/O Modules (e.g., digital/analog I/O): Other modular I/O cards that can be installed in the same PacDrive rack as the MC-41110400 drives, creating a unified control system for both motion and machine logic.

ELAU Epas-4 Software Suite: The engineering and configuration software (now often integrated into Rockwell’s tools) used to program the master controller, configure the MC-41110400 drives, tune the servo loops, and develop the HMI application.

SERCOS or EtherCAT Cables: The high-speed real-time communication cables that may be used to connect the controller to the drive modules or for system synchronization, depending on the PacDrive generation.

Installation, Maintenance, and Full-Cycle Support

Installation of the ELAU MC-41110400 involves inserting it securely into its designated slot in the PacDrive rack, ensuring it is properly seated on the backplane. Critical connections include the high-power output to the corresponding servo motor (using specified motor feedback and power cables) and ensuring the shared DC bus connections within the rack are secure. Installation must follow strict EMC guidelines, with proper separation of power and signal cables and correct grounding to ensure noise immunity, which is critical for stable servo operation.

Routine maintenance is primarily focused on monitoring and environment. The module’s status is fully accessible through the system’s diagnostic software, which can display temperatures, current outputs, and error logs. Keeping the cabinet clean and ensuring adequate cooling is vital. The module itself is not field-serviceable; if diagnostics indicate a hardware fault, the standard procedure is to replace the module. Our support for the MC-41110400 and the broader PacDrive system includes providing detailed technical documentation, assisting with configuration and tuning for optimal performance, and supplying genuine, compatible replacement modules. We can also assist with system migration or integration strategies, ensuring you maintain the performance and reliability of your automated machinery.

For precise motion control in demanding automation applications, understanding your system’s components is key. Contact us for detailed compatibility information, technical data, and support for your ELAU PacDrive system and MC-41110400 modules.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: