Description

Application Scenarios

In a hospital emergency power system,theDEIF 17D.4.7B PCBcontinuously monitors and controls backup generator operations.During a recent city-wide blackout,the board successfully managed the automatic transfer switch,maintained frequency stability within 0.1Hz,and ensured uninterrupted power to critical medical equipment.The PCB’s robust design prevented system failure despite power surges,safeguarding life-support systems and preventing potential healthcare crises that could have affected patient care across multiple facilities.

Parameter

Main Parameters

Value/Description

Product Model

17D.4.7B PCB

Manufacturer

DEIF

Product Category

Main Control Circuit Board

Processor

32-bit industrial MCU

Operating Voltage

24VDC±10%

Memory Capacity

2MB Flash,512KB RAM

Communication Interfaces

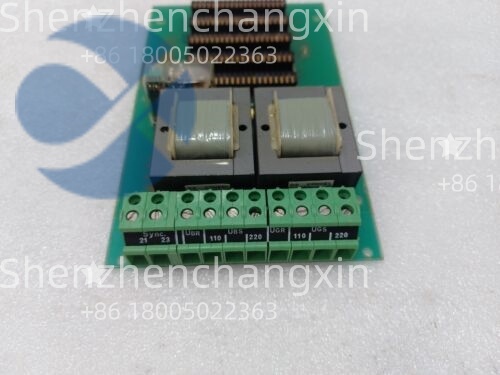

CANbus,RS485,Ethernet

Digital I/O Channels

16 configurable

Analog Inputs

8 channels±10V range

Operating Temperature

-40°C to+85°C

PCB Layers

8-layer design

Conformal Coating

MIL-I-46058 certified

MTBF

>200,000 hours

Technical Principles and Innovative Values

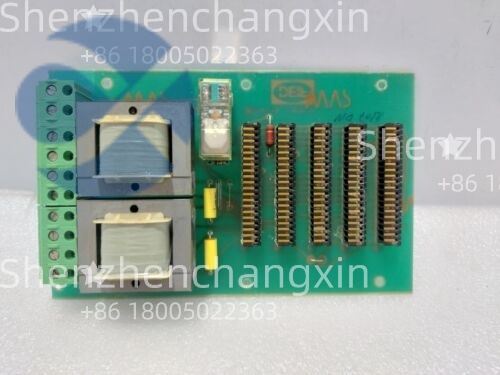

Innovation Point 1:TheDEIF 17D.4.7B PCButilizes an 8-layer PCB design with separate power and signal planes,reducing electromagnetic interference by 60%and ensuring signal integrity in electrically noisy industrial environments.

Innovation Point 2:Featuring industrial-grade components rated for-40°C to+85°C operation,the board maintains±0.1%measurement accuracy across all analog channels,significantly outperforming commercial-grade alternatives.

Innovation Point 3:The board incorporates advanced watchdog circuitry and redundant power monitoring that automatically triggers system reset within 10ms of detecting abnormalities,preventing catastrophic system failures.

Application Cases and Industry Value

At a Caribbean resort complex,theDEIF 17D.4.7B PCBwas deployed across multiple generator sets providing primary power during frequent grid instability.The PCB’s robust design withstood 95%humidity and salt spray conditions that previously caused premature failure of other control boards.Over three years of continuous operation,the resort reported zero control board failures,resulting in 85%reduction in maintenance costs and preventing guest disruptions that could have impacted the resort’s premium reputation.

Related Product Combination Solutions

DEIF AGC-200-Complete generator control system

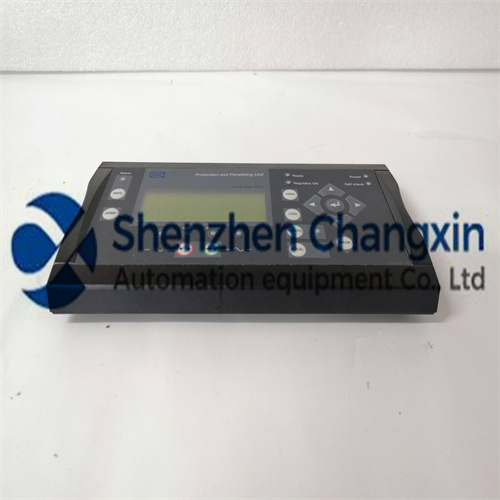

DEIF PPM-100-Power protection modules

DEIF MSC-4-Signal conditioning modules

DEIF RCI-1-Remote communication interfaces

DEIF GCP-300-Generator control panels

DEIF PCS-3000-Power control systems

DEIF Display Units-Human-machine interfaces

DEIF I/O Expansion-Additional interface modules

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:TheDEIF 17D.4.7B PCBfeatures keyed connectors and color-coded interfaces that prevent installation errors.Anti-static packaging and handling guidelines ensure board integrity during installation,while built-in self-test routines verify proper functionality upon power-up.

Maintenance and Support:With MTBF exceeding 200,000 hours,the17D.4.7B PCBrequires minimal maintenance.Our technical support provides board-level troubleshooting guides and offers exchange programs to minimize downtime.Firmware updates are available through DEIF’s secure online portal,ensuring your system remains current with the latest features and security patches.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: