Description

Product Overview

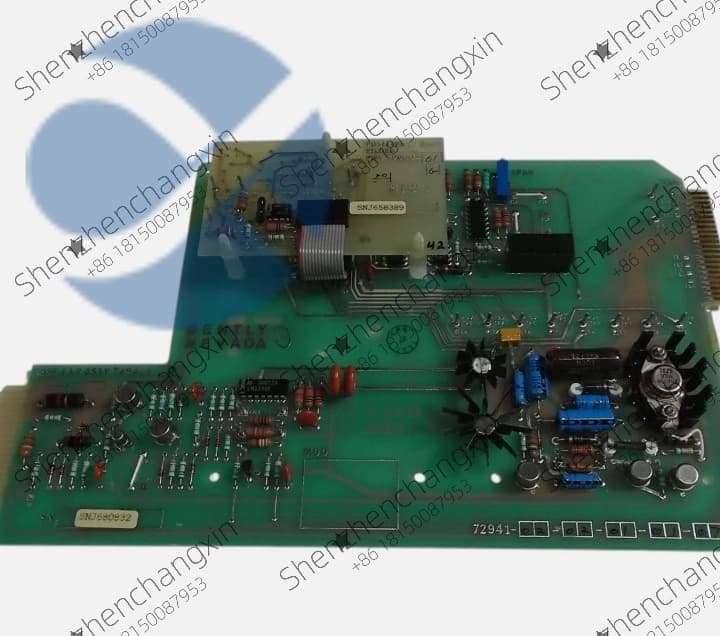

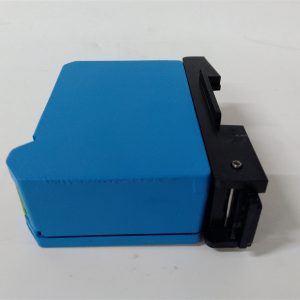

TheBENTLY 72941-02-02-01-01-07is a high-performance vibration monitoring module designed specifically for industrial machinery protection and condition monitoring applications.This sophisticated module serves as a critical component in BENTLY’s comprehensive machinery protection systems,providing precise vibration measurement and analysis capabilities for rotating equipment across various industrial sectors.TheBENTLY 72941-02-02-01-01-07is engineered to handle both dynamic and static vibration signals with exceptional accuracy,making it an indispensable component in demanding industrial environments where equipment reliability and predictive maintenance are paramount.

As part of BENTLY’s extensive machinery protection portfolio,the72941-02-02-01-01-07module offers robust performance across various industrial applications including power generation,petrochemical processing,and manufacturing facilities.The module’s advanced architecture features sophisticated signal processing capabilities and multiple input interfaces,enabling it to process vibration signals from various transducer types including proximity probes,velocity sensors,and accelerometers.With support for multiple communication protocols and comprehensive diagnostic features,theBENTLY 72941-02-02-01-01-07ensures seamless integration into existing control systems while maintaining high reliability and operational stability even in the most challenging industrial conditions.

Technical Specifications

Parameter Name

Parameter Value

Product Model

BENTLY 72941-02-02-01-01-07

Manufacturer

BENTLY

Product Type

Vibration Monitoring Module

Input Channels

2 channels(vibration/position)

Input Type

Proximity probe,velocity sensor,accelerometer

Frequency Response

0.5 Hz to 10 kHz

Dynamic Range

80 dB

Measurement Accuracy

±1%of full scale

Output Signals

4-20mA,0-10VDC,RS-485

Communication Protocols

Modbus RTU,Profibus,Ethernet/IP

Supply Voltage

24VDC nominal

Power Consumption

Maximum 15W

Operating Temperature

-40°C to+85°C

Storage Temperature

-55°C to+105°C

Protection Rating

IP67(suitable for harsh environments)

Physical Dimensions

150 x 100 x 50 mm

Weight

0.6 kg

Installation Method

DIN rail mounting

Certification Standards

CE,UL,CSA,ATEX

Main Features and Advantages

TheBENTLY 72941-02-02-01-01-07vibration monitoring module offers several key advantages that make it stand out in industrial machinery protection applications.High precision vibration measurement capability is one of its most significant features,enabled by advanced signal processing algorithms and high-resolution analog-to-digital conversion.This combination provides exceptional measurement accuracy and signal processing capabilities,ensuring reliable performance in complex machinery monitoring tasks across various industrial sectors.

Multiple sensor interface support is another critical feature,with the72941-02-02-01-01-07offering comprehensive input capabilities including proximity probes for shaft position measurement,velocity sensors for bearing vibration monitoring,and accelerometers for high-frequency vibration analysis.This versatility allows the module to handle diverse vibration measurement requirements,making it suitable for applications requiring both low-frequency and high-frequency vibration analysis.The module’s compatibility with various sensor types further enhances its flexibility in industrial environments.

Advanced diagnostic and communication capabilities represent a significant advantage of theBENTLY 72941-02-02-01-01-07,with support for multiple industrial communication protocols including Modbus RTU,Profibus,and Ethernet/IP.This multi-protocol support ensures seamless integration with various control systems and asset management platforms,reducing system integration costs and complexity.The module’s comprehensive diagnostic features include real-time trend monitoring,alarm management,and predictive maintenance capabilities,enabling early detection of machinery faults and preventing catastrophic failures.

Application Field

TheBENTLY 72941-02-02-01-01-07vibration monitoring module finds extensive applications across multiple industrial sectors due to its versatile machinery protection capabilities.In the power generation industry,the72941-02-02-01-01-07is widely used in turbine-generator sets,pumps,and compressors for continuous vibration monitoring and protection.Its high precision measurement ensures accurate detection of imbalance,misalignment,and bearing defects,contributing to the reliability and availability of power generation equipment.

In the petrochemical industry,theBENTLY 72941-02-02-01-01-07serves critical functions in compressor trains,pumps,and fan systems where continuous operation is essential for process safety and efficiency.The module’s robust design and high reliability make it suitable for harsh industrial environments typical in petrochemical plants,ensuring continuous operation and process safety.Its advanced diagnostic capabilities enable predictive maintenance strategies,reducing unplanned downtime and maintenance costs.

Manufacturing applications benefit significantly from the72941-02-02-01-01-07’s capabilities in machine tool monitoring and production equipment protection.The module processes vibration signals from critical rotating equipment including motors,gearboxes,and spindles,enabling precise condition monitoring and early fault detection.Its fast response time and high accuracy contribute to improved equipment reliability and production efficiency in various manufacturing sectors including automotive,steel,and paper production.

Related Products

BENTLY 3300/16:Vibration monitor that complements the72941-02-02-01-01-07in machinery protection applications

BENTLY 3500/42M:Proximitor transducer interface module for shaft position measurement

BENTLY 3300/20:Proximity transducer system for vibration and position monitoring

BENTLY 3500/25:Keyphasor module for phase reference measurement

BENTLY 3300/08:Velocity transducer interface module for bearing vibration monitoring

BENTLY 3500/32:Relay module for alarm and trip functions

BENTLY 3300/45:Dual channel proximity transducer system

BENTLY 3500/50:Communication gateway module for system integration

BENTLY 3300/53:Dual channel accelerometer interface module

BENTLY 3500/92:System power supply unit for vibration monitoring systems

Installation and Maintenance

Pre-installation preparation:Before installing theBENTLY 72941-02-02-01-01-07,ensure that the working environment temperature remains within the specified range of-40°C to+85°C.The module should be installed in a standard control cabinet using DIN rail mounting method.Verify that adequate space is available for proper heat dissipation and ensure that all mounting hardware is compatible with the module dimensions.Use shielded cables for all connections to minimize electromagnetic interference and ensure signal integrity.Proper grounding practices must be followed to prevent ground loops and ensure accurate measurement.

Maintenance recommendations:Regular maintenance is essential for optimal performance of theBENTLY 72941-02-02-01-01-07.Periodically inspect module connections and mounting to ensure they remain secure and free from corrosion.Check cable integrity and replace any damaged cables immediately.Monitor LED indicators and utilize real-time monitoring functions to verify proper operation.It is recommended to perform comprehensive equipment inspections annually,including functional testing and environmental condition assessment.Maintain proper documentation of maintenance activities and keep spare modules available for critical applications to minimize downtime during replacement.

Product Guarantee

We guarantee that everyBENTLY 72941-02-02-01-01-07vibration monitoring module meets original manufacturer specifications and undergoes rigorous testing before shipment.Each unit is backed by our comprehensive technical support and a standard warranty period,ensuring that customers receive reliable and high-quality products.Our commitment to quality extends beyond the initial purchase,with dedicated after-sales support available to address any technical questions or application challenges.We maintain strict quality control procedures throughout our supply chain to ensure that all72941-02-02-01-01-07modules deliver consistent performance and reliability in industrial machinery protection applications.Our team of technical experts is available to provide guidance on installation,configuration,and troubleshooting,ensuring optimal performance of theBENTLY 72941-02-02-01-01-07in your specific application environment.

Contact: Mandy Contact number: +8618150087953 Web site: www.cxplcmro.com Email: sales@cxplcmro.com

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: