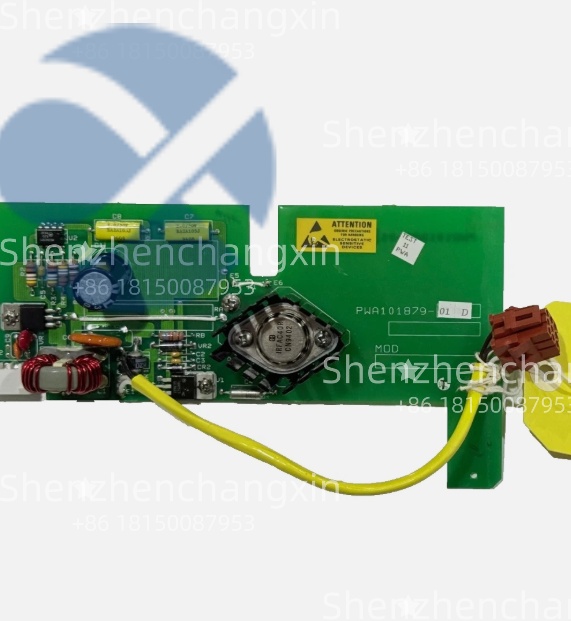

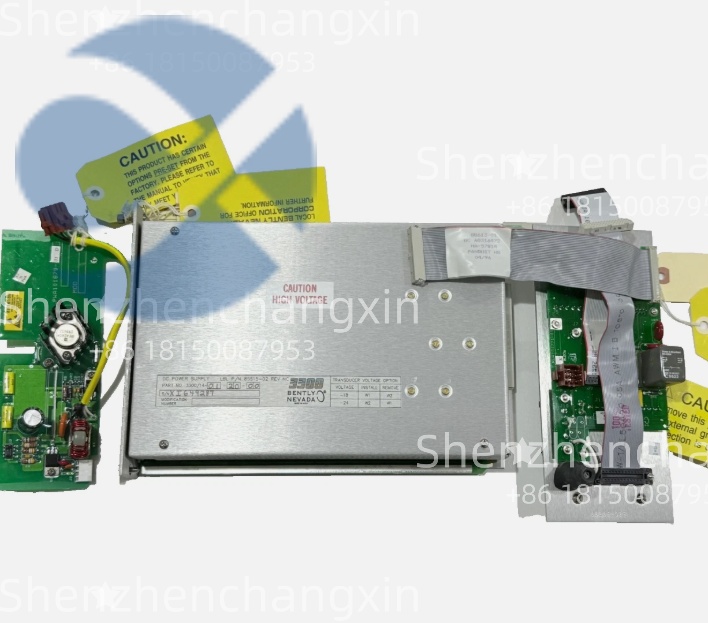

Description

Application Scenarios

In a large-scale power plant,the BENTLEY NEVADA 3500-15 is used to monitor the vibrations of steam turbines and generators.By continuously assessing the condition of the equipment,the system helps prevent costly failures,improves operational uptime,and reduces the need for unscheduled maintenance.The 3500-15 has helped the facility maintain peak performance levels while minimizing downtime,ensuring that production schedules are met with greater reliability.

In the oil and gas industry,where equipment failure can have serious financial and safety consequences,the BENTLEY NEVADA 3500-15 serves as a critical tool for monitoring pumps and compressors.By detecting early signs of wear or malfunction,the system allows for timely interventions,reducing the risk of catastrophic failures and extending the life of the machinery.

Main Parameters

Main Parameters Value/Description

Product Model 3500-15

Manufacturer BENTLEY NEVADA

Product Category Vibration Monitoring and Protection Module

Vibration Measurement Range 0.01 to 1000 Hz

Power Supply 24 VDC

Signal Output 4-20 mA,0-10 VDC

Communication Protocol Modbus,TCP/IP,Profibus

Mounting Type Panel Mountable

Operating Temperature Range-40°C to 70°C

Environmental Protection IP67

Dimensions(W x H x D)120mm x 150mm x 45mm

Certification CE,UL

Technical Principles and Innovative Values

Real-Time Vibration Monitoring:The 3500-15 provides continuous real-time vibration monitoring of industrial rotating equipment,offering early detection of potential problems that could lead to failures.

Advanced Diagnostics:This system features advanced diagnostic capabilities,identifying specific faults such as imbalance,misalignment,or bearing defects,enabling faster decision-making and maintenance actions.

Wide Frequency Range:With a vibration measurement range from 0.01 to 1000 Hz,the 3500-15 can detect both low and high-frequency vibrations,making it suitable for a wide range of industrial applications.

Integration with DCS and PLC:The system integrates easily with Distributed Control Systems(DCS)and Programmable Logic Controllers(PLC),offering centralized monitoring and control.

Application Cases and Industry Value

In a major manufacturing facility,the BENTLEY NEVADA 3500-15 was deployed to monitor the vibration levels of critical motors and conveyors.The system detected abnormal vibration patterns that indicated a misaligned motor,which could have caused significant damage if left unchecked.By addressing the issue early,the company avoided costly repairs and production delays,saving both time and money.The 3500-15 not only improved operational efficiency but also contributed to the facility’s safety standards.

In the mining industry,where rotating machinery operates under harsh conditions,the 3500-15 helped a mining company monitor conveyor belts and crushers.It provided real-time alerts on mechanical failures,enabling proactive maintenance and reducing unplanned downtime.The system’s ability to integrate with the plant’s existing automation system streamlined operations and contributed to safer,more reliable production.

Related Product Combination Solutions

BENTLEY NEVADA 3500-22M:A monitoring system for proximity sensors that works in conjunction with the 3500-15 to enhance the protection of rotating machinery.

BENTLEY NEVADA 3500-25:A vibration monitoring module designed for multi-channel input applications,ideal for integrating with the 3500-15 for larger systems.

BENTLEY NEVADA 3500-10:This system provides protection for critical machinery by measuring parameters like temperature and pressure,complementing the 3500-15 vibration module.

BENTLEY NEVADA 3500-90:An advanced vibration system for real-time data collection and diagnostics that integrates seamlessly with the 3500-15.

BENTLEY NEVADA 3500-44M:A comprehensive monitoring solution that includes machine protection and diagnostics,ideal for large-scale operations when paired with the 3500-15.

Installation,Maintenance,and Full-Cycle Support

Installation:

The BENTLEY NEVADA 3500-15 is designed for straightforward installation in control panels.Its compact design ensures it fits easily in most industrial setups.The system is equipped with plug-and-play connectors and simple calibration tools for quick and efficient deployment.

Maintenance:

Routine maintenance for the 3500-15 involves regular inspection of the vibration sensors,checking for proper mounting and alignment.The system’s built-in diagnostics provide real-time fault detection,which helps operators address issues before they escalate.

Support:

BENTLEY NEVADA offers full support for the 3500-15,including remote troubleshooting,software updates,and onsite service.The company’s expert technicians are available to provide fast resolution to any problems,ensuring that your machinery protection system operates without interruption.

Call to Action

The BENTLEY NEVADA 3500-15 is your go-to solution for machinery protection,offering real-time vibration monitoring,advanced diagnostics,and seamless integration with existing systems.Enhance the safety,reliability,and efficiency of your rotating equipment by investing in the 3500-15.Contact us today to discover how this innovative solution can boost your operational performance and prevent costly machinery breakdowns.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: