Description

Application Scenarios

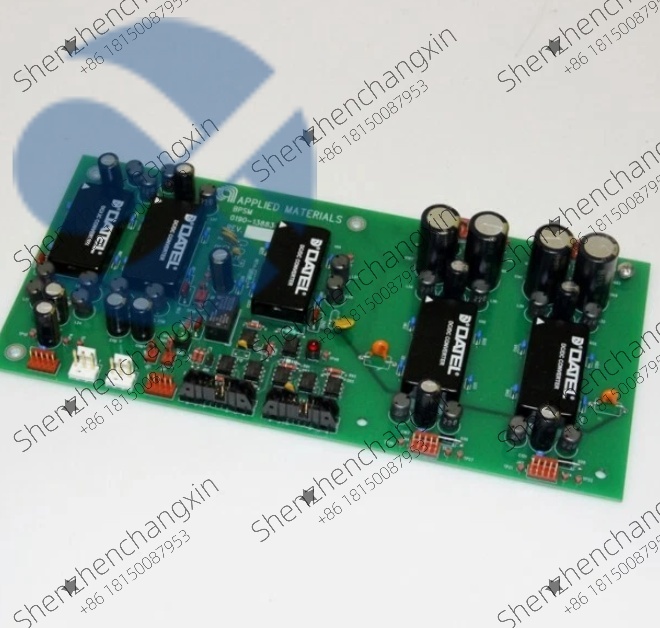

In a semiconductor fab producing 300mm wafers for memory devices,theApplied Materials AKT BPSM Board 0190-13883-A Rev.01manages the backside pressure control during titanium nitride(TiN)barrier layer deposition.During wafer processing,the board precisely regulates the helium backside cooling pressure to maintain optimal wafer temperature uniformity across the entire platen surface.This precise thermal management prevents wafer warpage and ensures consistent film thickness distribution critical for advanced node devices.The board’s high-speed pressure control capabilities enable rapid pressure adjustments during wafer handling sequences,minimizing process cycle time while maintaining process stability.

Technical Parameters

Main Parameters

Value/Description

Product Model

0190-13883-A

Revision

Rev.01

Manufacturer

Applied Materials

Product Category

BPSM Control Board

Compatible Systems

AKT PVD Series Sputtering Systems

Function

Backside Pressure Service Module Control

Input Voltage

24V DC or 48V DC(system dependent)

Communication Interface

Proprietary fieldbus to main system controller

Pressure Control Channels

Multiple channel pressure control

Sensor Interfaces

Pressure transducer inputs

Control Outputs

Proportional valve control signals

Operating Temperature

15°C to 35°C(cleanroom environment)

Board Type

High-reliability PCB with conformal coating

Component Rating

Industrial-grade with extended lifecycle

Technical Principles and Innovative Values

Innovation Point 1:Precision Pressure Control Architecture.TheApplied Materials AKT BPSM Board 0190-13883-A Rev.01implements advanced PID control algorithms with adaptive tuning capabilities that maintain backside pressure within±0.1%of setpoint despite process variations.The board’s high-resolution digital-to-analog converters and precision pressure sensors enable real-time adjustments to helium flow rates,ensuring optimal wafer thermal contact throughout the deposition process.This precision is critical for maintaining wafer temperature uniformity during high-power sputtering processes.

Innovation Point 2:Multi-Channel Synchronized Control.The board features independent yet synchronized pressure control channels that can manage multiple wafer zones simultaneously.This capability enables advanced wafer-level pressure profiling for complex wafer geometries and large-diameter substrates.The synchronized control ensures uniform pressure distribution across the wafer backside,preventing localized hot spots and ensuring consistent film properties across the entire wafer surface.

Innovation Point 3:Advanced Diagnostic and Prognostic Capabilities.Incorporating built-in self-test routines and continuous health monitoring,the board provides early warning of potential component degradation.The system tracks performance metrics such as valve response times,sensor drift,and control loop stability,enabling predictive maintenance before process quality is affected.This proactive approach maximizes tool uptime and reduces unscheduled maintenance events.

Application Cases and Industry Value

Case Study:Advanced DRAM Manufacturing Process.A major semiconductor manufacturer implemented theApplied Materials AKT BPSM Board 0190-13883-A Rev.01in their AKT PVD systems for critical barrier layer deposition in sub-20nm DRAM production.The enhanced pressure control stability improved wafer-level temperature uniformity by 40%,resulting in a 15%reduction in film thickness variation.This improvement directly translated to a 3%increase in yield for the critical barrier layer process step.The board’s reliability in continuous 24/7 operation reduced unscheduled downtime by 60%compared to previous versions,contributing to an estimated$2.8 million annual savings in increased productivity and reduced maintenance costs across the fab.

Related Product Combination Solutions

AKT Main System Controller:Central control unit communicating with theBPSM Board

Pressure Control Valves:Proportional valves controlled by the0190-13883-Aboard

Pressure Transducers:High-precision sensors providing feedback to the BPSM system

Heating Elements:Temperature control components integrated with pressure control

Wafer Handling Robotics:Coordination with the BPSM for wafer transfer sequences

Vacuum System Components:Integration with main chamber pressure control

Process Gas Controllers:Coordination with gas delivery systems

Installation,Maintenance,and Full-Cycle Support

Installation of theApplied Materials AKT BPSM Board 0190-13883-A Rev.01requires certified technician training and must be performed in controlled cleanroom conditions.Proper ESD protection and handling procedures are critical to prevent damage to sensitive components.Board replacement requires system vacuum venting and proper sequence following Applied Materials’documented procedures to ensure system integrity and prevent contamination.

Preventive maintenance includes regular calibration checks of pressure sensors and control valves,verification of board communication integrity,and inspection of electrical connections.The board’s built-in diagnostics provide valuable data for predictive maintenance scheduling.Component-level repair should only be performed by authorized service personnel using genuine Applied Materials components.

We provide comprehensive support for theApplied Materials AKT BPSM Board 0190-13883-A Rev.01,including technical documentation,installation guidance,and genuine replacement boards.Our support team understands the critical nature of semiconductor tool uptime and offers rapid response to minimize production impacts.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: