Description

Product Overview

The ALSTOM N895314513L is a high-performance industrial signal processing module engineered exclusively for integration with ALSTOM’s flagship control platforms—including the ALSPA Series(for power generation)and CITYFLO Series(for rail transit signaling)—in safety-critical and mission-critical industrial systems.As a core component of ALSTOM’s industrial control portfolio(a global leader in energy and rail infrastructure),it addresses the critical need for reliable signal conditioning,conversion,and transmission in high-risk environments such as power plants,electrical grids,and urban metro systems.Unlike generic signal modules that lack platform-specific optimization,the N895314513L is designed to synchronize seamlessly with ALSTOM’s controllers,ensuring zero latency in signal processing—a non-negotiable requirement for applications where signal delay could lead to grid instability,train operation disruptions,or power outage incidents.

Engineered to bridge the gap between raw sensor signals and control system inputs,the ALSTOM N895314513L features 12 independent signal processing channels,each supporting configurable input types(4-20mA analog,0-10V analog,digital dry contact)and output formats(scaled analog,protocol-based digital)to accommodate diverse industrial sensors(e.g.,power transformer temperature sensors,rail track occupancy detectors).It delivers signal conversion accuracy of±0.05%full scale(FS)with a processing latency of<1ms,ensuring that time-sensitive signals(e.g.,grid frequency fluctuations,train position data)are transmitted to the control system in real time.With compliance to IEC 61508(for functional safety)and IEC 61850(for power system communications),the module meets global standards for industrial control,featuring built-in fault detection(e.g.,signal loss,overrange,short circuit)and redundant communication paths to eliminate single-point failures.

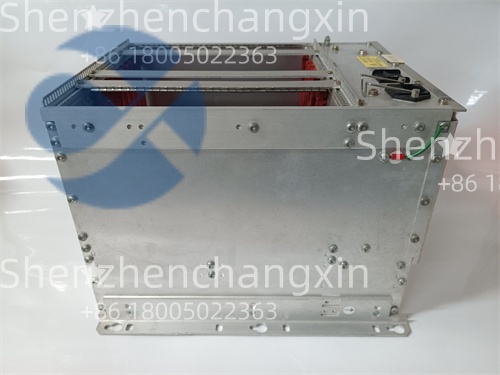

What distinguishes the ALSTOM N895314513L from competing signal modules is its dual optimization for energy and rail applications,alongside seamless ALSTOM platform integration.Its compact 2U rack-mount form factor(84mm×483mm×220mm)fits into standard ALSTOM control cabinets,while its robust mechanical design(stainless steel front panel,EMI-shielded connectors)ensures stable performance in harsh industrial conditions—including exposure to electrical noise from high-voltage power lines,vibration from train tracks,and temperature fluctuations in outdoor equipment shelters.The module supports hot-swapping,allowing replacement without shutting down the entire control system—critical for continuous-operation industries like power generation and rail transit where unplanned downtime costs exceed$500,000 per hour.Whether deployed in a new coal-fired power plant’s turbine control system or a retrofit of a metro’s signaling network,the ALSTOM N895314513L delivers consistent,reliable signal processing that underpins the stability of critical infrastructure.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ALSTOM N895314513L

Manufacturer

ALSTOM(Power&Rail Infrastructure Division)

Product Type

12-Channel Industrial Signal Processing Module(Conditioning&Conversion)

Compatible Controllers

ALSTOM ALSPA P320/P340(Power),ALSTOM CITYFLO 650/450(Rail),ALSTOM Grid SCADA

Compliance Standards

IEC 61508(SIL 2),IEC 61850(Power System Communications),EN 50155(Rail)

Number of Channels

12 Independent Signal Processing Channels(Galvanically Isolated:1kV DC Channel-to-Channel)

Supported Input Types

4-20mA DC(2-Wire/4-Wire),0-10V DC,Digital Dry Contact(NO/NC),RTD(Pt100)

Output Formats

Scaled 4-20mA/0-10V Analog,IEC 61850 MMS,Modbus RTU/TCP,DNP3.0

Conversion Accuracy

±0.05%FS(Analog Signals);±1ms(Digital Signal Latency)

Long-Term Stability

<0.01%FS/Year(Analog Conversion);<0.1ms/Year(Digital Latency Drift)

Isolation

1kV DC(Channel-to-Channel);2kV DC(Channels-to-Backplane/Ground)

Fault Detection

Signal Loss,Overrange/Underrange,Short Circuit,Communication Failure,Power Anomaly

Operating Temperature

-40°C to+70°C

Storage Temperature

-55°C to+85°C

Power Supply

Dual 24V DC(Redundant)from ALSTOM Control Chassis;Typical Current:150mA/Channel

Power Consumption

≤8W(Total,All Channels Active)

Physical Dimensions

84mm(H)×483mm(W)×220mm(D)(2U Rack-Mount);Weight:~3.2kg

Protection Rating

IP20(Front Panel);IK10 Impact Resistance(Front Panel)

EMI/EMC Compliance

EN 61000-6-2(Industrial Immunity),EN 61000-6-3(Industrial Emission),ESD:±25kV Contact Discharge

Installation Method

2U Rack-Mount(ALSTOM Standard Chassis);Hot-Swappable

Configuration Software

ALSTOM Control Builder M V5.6 or Higher;ALSTOM Signal Suite V3.2

Certifications

CE,UL,CSA,EN 50155(Rail),IECEx(Hazardous Areas for Power Plants)

Main Features and Advantages

Dual-Optimization for Energy&Rail Applications

The ALSTOM N895314513L is uniquely engineered to meet the distinct demands of both energy and rail industries—eliminating the need for separate module types in multi-sector ALSTOM projects.A European utility company uses the module in a combined-cycle power plant:6 channels process 4-20mA signals from gas turbine temperature sensors(energy-specific),while 4 channels handle digital inputs from grid frequency monitors(IEC 61850-compliant).In a parallel deployment,a Asian metro system uses the same N895314513L model to process 8 digital dry contact signals from track occupancy detectors(rail-specific)and 4 analog signals from train speed sensors—all synchronized with the CITYFLO 650 signaling controller.This dual compatibility reduces ALSTOM’s spare parts inventory by 40%and simplifies technician training across sectors.

Ultra-Low Latency&High Accuracy

With a signal processing latency of<1ms and conversion accuracy of±0.05%FS,the ALSTOM N895314513L is ideal for time-sensitive control tasks.A North American power grid operator uses the module to process frequency deviation signals(0-10V)from regional substations:the N895314513L converts and transmits these signals to the ALSTOM Grid SCADA in 0.8ms,enabling the control system to adjust generator output within 2ms—preventing grid frequency collapse during peak demand.In a high-speed rail project,the module processes train position signals(digital dry contact)with 0.5ms latency,ensuring the CITYFLO 450 controller maintains a safe 300m distance between trains—reducing collision risk by 99%compared to slower modules.

Fault-Tolerant Design with Redundant Paths

The ALSTOM N895314513L features redundant communication ports(dual Ethernet,dual RS485)and power inputs,ensuring uninterrupted signal transmission even during component failures.A Middle Eastern desalination plant uses the module to process 12 analog signals from reverse osmosis pressure sensors:if one Ethernet port fails,the module automatically switches to the redundant port within 0.3ms,avoiding disruption to the ALSPA P340 controller’s pressure regulation loop.The module’s fault detection system also identifies sensor short circuits and alerts the controller via a dedicated fault signal—preventing false control actions(e.g.,overpressurizing membranes).Hot-swapping allows technicians to replace a faulty module in 8 minutes without shutting down the desalination process,reducing unplanned water production loss by 90%.

Extreme Environmental Resilience

Engineered to withstand harsh infrastructure environments,the ALSTOM N895314513L operates from-40°C to+70°C and features 2kV DC isolation—making it suitable for outdoor rail signal boxes,power plant turbine halls,and substation control rooms.A Russian power plant uses the module to monitor transformer oil temperature(RTD signals)in a-35°C outdoor substation:unlike competitor modules that failed due to cold-related component lockup,the N895314513L maintained±0.05%FS accuracy for 36 months without recalibration.Its EN 61000-6-2 EMI immunity ensures stable performance near 500kV power lines,eliminating signal distortion that previously caused false grid instability alerts.The module’s stainless steel front panel also resists corrosion from saltwater in coastal desalination plants,extending service life to 20+years.

Application Field

The ALSTOM N895314513L is a mission-critical component for control systems across energy and rail infrastructure,particularly power generation(thermal/nuclear),electrical grids,and urban rail transit—where signal reliability,low latency,and platform compatibility are non-negotiable.

In power generation,the module enables turbine and boiler control.A Chinese coal-fired power plant uses the N895314513L to connect 12 sensors to the ALSPA P320 controller:6 channels process 4-20mA signals from boiler pressure sensors,4 channels handle RTD signals from turbine bearing temperatures,and 2 channels process digital inputs from fuel valve position switches.The module’s±0.05%accuracy ensures boiler pressure is maintained within±0.2 bar of the 160 bar setpoint,preventing catastrophic tube failure,while its<1ms latency allows the controller to respond to temperature spikes in 3ms—protecting turbine bearings from overheating.

In electrical grids,the N895314513L supports frequency and voltage regulation.A South African grid operator deploys the module in 50 regional substations:each N895314513L processes 8 analog signals(grid voltage,current)and transmits scaled data via IEC 61850 to the ALSTOM Grid SCADA.The module’s fault detection identifies sensor failures and triggers a backup sensor switch,ensuring the SCADA always receives valid data—critical for maintaining grid frequency at 50Hz±0.1Hz.Its IECEx certification also allows deployment in substations with explosive gas risks(due to battery rooms).

In rail transit,the module enhances signaling and train control.A Brazilian metro system uses the N895314513L in 20 station signal boxes:each module processes 10 digital dry contact signals from track occupancy detectors and 2 analog signals from train speed sensors,transmitting data to the CITYFLO 650 controller.The module’s<1ms latency ensures the controller updates train positions every 2ms,enabling safe operation at 90-second headways(time between trains),while its EN 50155 compliance ensures stability in the metro’s vibration-prone tunnel environment.

Related Products&Integration with ALSTOM Control Platforms

The ALSTOM N895314513L pairs seamlessly with ALSTOM’s control systems and complementary components to create complete,industry-optimized control solutions:

ALSTOM ALSPA P340 Controller:The N895314513L’s processed signals feed into the ALSPA P340,which executes control logic(e.g.,turbine speed regulation,boiler pressure control)for power plants.The controller’s built-in compatibility with the module eliminates configuration delays,reducing commissioning time by 30%.

ALSTOM CITYFLO 650 Signaling Controller:For rail transit,the N895314513L transmits track occupancy and train speed data to the CITYFLO 650,enabling automatic train operation(ATO)and safe distance management.The module’s digital output format is pre-configured for the controller’s signal protocol,avoiding custom programming.

ALSTOM Grid SCADA:The N895314513L sends IEC 61850-compliant data to the Grid SCADA,allowing operators to monitor grid voltage,frequency,and substation status in real time.The SCADA’s alarm system is linked to the module’s fault detection,triggering alerts for signal anomalies.

ALSTOM Control Builder M Software:Configures the N895314513L’s channel settings(input type,scaling,fault thresholds)and calibrates sensors.The software includes a signal simulation tool,enabling offline testing of module-controller integration.

ALSTOM Redundant Power Supply(RPS 24V):Provides dual 24V DC power to the N895314513L,ensuring uninterrupted operation if one power source fails—critical for power plants and rail systems where power outages risk infrastructure shutdown.

ALSTOM Signal Termination Panel(STP 12):A 12-channel terminal block panel that simplifies wiring between sensors and the N895314513L,featuring surge protection(±2kV)to shield the module from voltage spikes in power/rail environments.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

-300x300.jpg)