Description

Application Scenarios

At a 1,200 MW thermal power plant in Southeast Asia,operators faced inconsistent performance in boiler feedwater control due to signal drift in aging analog output modules.The legacy boards exhibited±0.5%deviation,causing fluctuating drum level control and risking boiler trips.The engineering team replaced them with the ABB YPT111A 61205055D Board,which offers±0.1%accuracy and galvanic isolation.After commissioning,the feedwater control loop stabilized,reducing level deviation by 80%and eliminating spurious trips for over 18 months.The plant’s automation manager credited the YPT111A’s precision and noise immunity for improving boiler safety and efficiency.

In a petrochemical refinery in the Middle East,the ABB YPT111A 61205055D Board was deployed in the reactor temperature control system to modulate fuel gas control valves.Prior to the upgrade,signal ripple caused oscillations in furnace temperature,affecting product yield.With the YPT111A’s stable 4–20 mA output and low ripple(<0.1%),temperature control improved significantly,maintaining setpoints within±1°C.Operators reported a 15%improvement in process consistency and reduced catalyst degradation.

Main Parameters

Parameter Value/Description

Product Model YPT111A 61205055D

Manufacturer ABB(Automation Products)

Product Category Analog Output(AO)Module

Number of Channels 8 isolated analog outputs

Output Signal 4–20 mA(configurable range)

Accuracy±0.1%of full scale

Resolution 16-bit DAC(Digital-to-Analog Converter)

Isolation Voltage 2500 VAC channel-to-ground and channel-to-channel

Load Impedance Up to 750Ω

Response Time<2 ms per channel

Communication Interface ABB proprietary backplane bus(for PM/CI series chassis)

Installation Method Chassis-mounted(in ABB PM86x,CI8xx cabinets)

Operating Temperature-10°C to+60°C(14°F to 140°F)

Environmental Protection Conformal coating option;meets IEC 61000-6-2 EMC standards

Note:High accuracy and isolation make this board ideal for closed-loop control,burner management,and safety-critical modulation.

Technical Principles and Innovative Values

Innovation Point 1:The ABB YPT111A 61205055D Board uses precision 16-bit DACs and opto-isolated output drivers to deliver stable,noise-free 4–20 mA signals,essential for accurate valve positioning and process regulation.

Innovation Point 2:Full galvanic isolation(2500 VAC)prevents ground loops and protects the DCS controller from voltage transients and EMI—critical in high-power industrial environments with VFDs and switchgear.

Innovation Point 3:Supports hot-swap capability in redundant systems,allowing module replacement without shutting down the control system—maximizing plant availability and minimizing forced outages.

Innovation Point 4:Onboard diagnostics with LED indicators per channel enable real-time monitoring of output status,fault conditions(e.g.,open circuit,overcurrent),and communication health—reducing troubleshooting time.

Innovation Point 5:Designed for seamless integration with ABB’s Symphony Plus engineering tools,the board auto-configures via the backplane and supports online calibration and verification through ABB Control Builder Plus software.

Application Cases and Industry Value

In a LNG liquefaction plant,the ABB YPT111A 61205055D Board was used to control anti-surge valves on centrifugal compressors.The high accuracy and fast response ensured precise modulation during load changes,preventing compressor surge events.Over three years,the system recorded zero surge incidents,contributing to the plant’s 99.95%mechanical availability.

At a pharmaceutical manufacturing facility,the YPT111A 61205055D was employed in reactor temperature and pressure control loops.The board’s stability and repeatability ensured consistent batch quality,helping the facility meet stringent FDA 21 CFR Part 11 compliance requirements for process validation.

Related Product Combination Solutions

ABB YPI111 61253429:Digital input board,often paired with the YPT111A for mixed I/O control in safety and sequencing logic.

ABB YPP120 61253431:Analog input board,used alongside the YPT111A for full analog signal processing in process loops.

ABB CI854 61253433:Communication interface module(e.g.,Profibus,Modbus)for connecting the YPT111A to external systems.

ABB PM864 61253430:Redundant CPU controller,commonly used with the YPT111A in high-availability DCS racks.

ABB YPQ202A:Digital I/O board,ideal for integrating discrete control with analog modulation in complex systems.

ABB 3BSE018101R1:24VDC power supply unit,ensuring stable power delivery to the YPT111A and chassis modules.

ABB Symphony Plus DCS Software:Engineering suite for configuring,calibrating,and diagnosing the YPT111A.

ABB 3HAC049287-001:Chassis adapter or mounting rack for integrating the YPT111A into ABB control cabinets.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB YPT111A 61205055D Board is simple:insert it into the designated slot in an ABB PM or CI series chassis,secure with the retention clip,and verify the power and communication LEDs.The module is auto-detected by the system,requiring no manual addressing.Terminal blocks are clearly labeled,and wiring guidelines ensure correct loop connections.

Routine maintenance is minimal due to the solid-state design.The onboard LED indicators provide per-channel status and fault detection.In redundant configurations,the board supports live replacement.We offer full lifecycle support,including configuration validation,calibration services,and failure analysis.With a global inventory of new,refurbished,and tested units,we ensure long-term availability for ABB DCS systems still in operation.

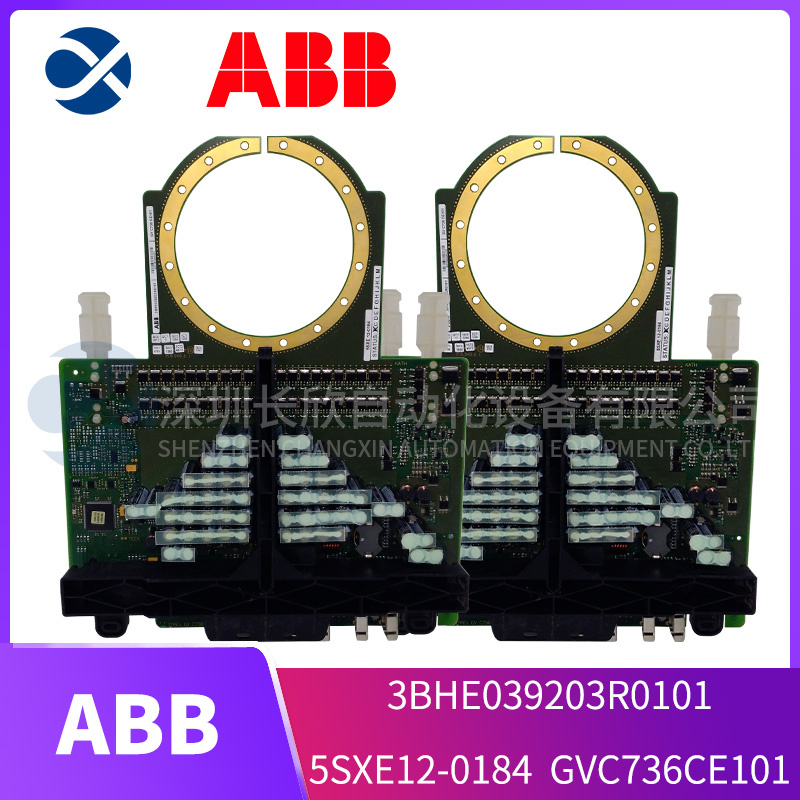

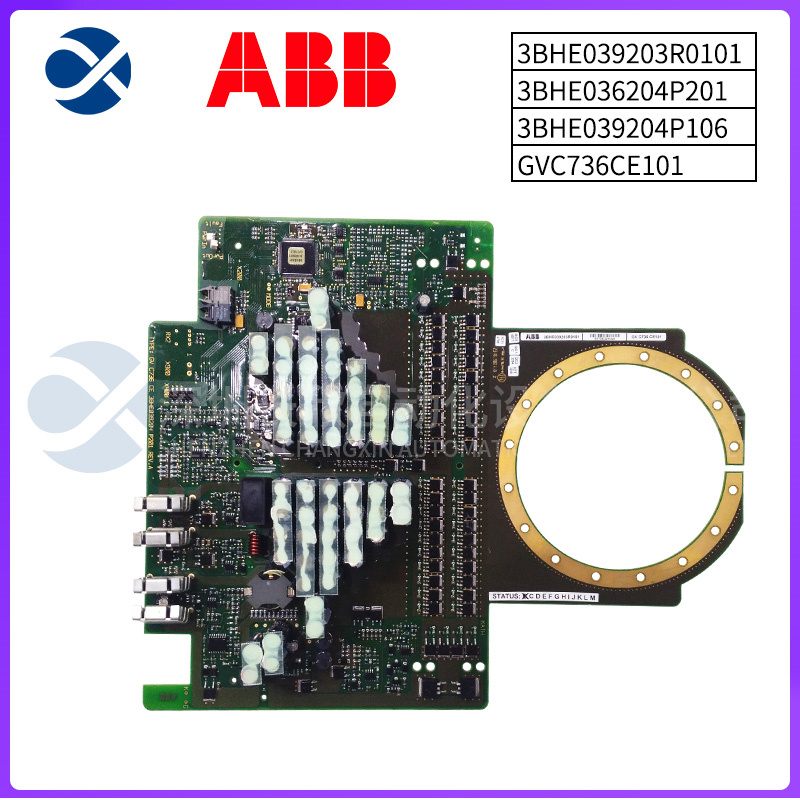

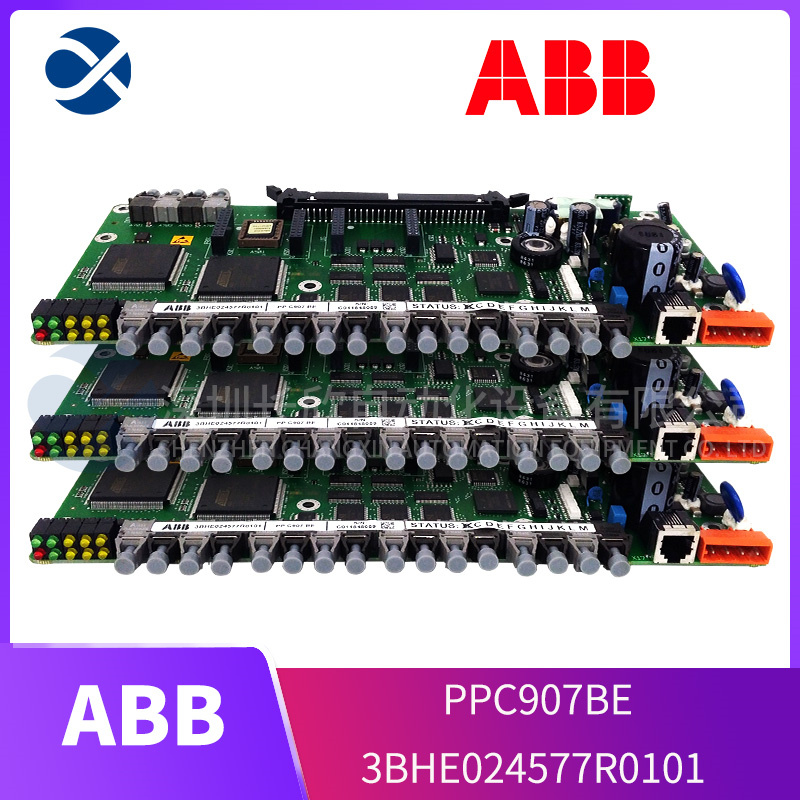

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: