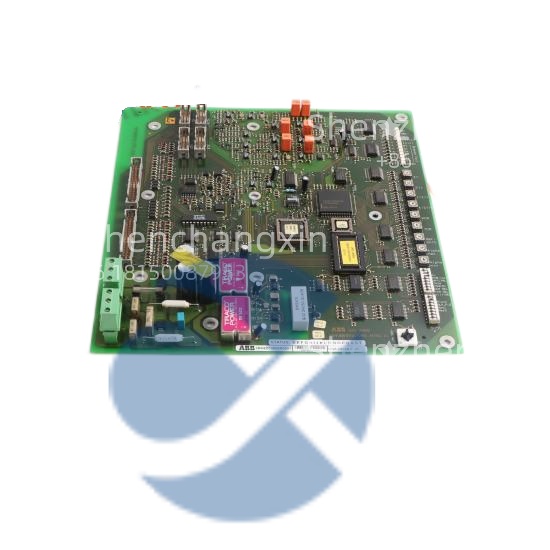

Description

Application Scenarios

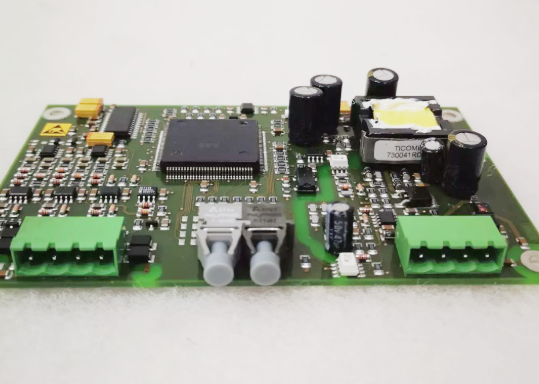

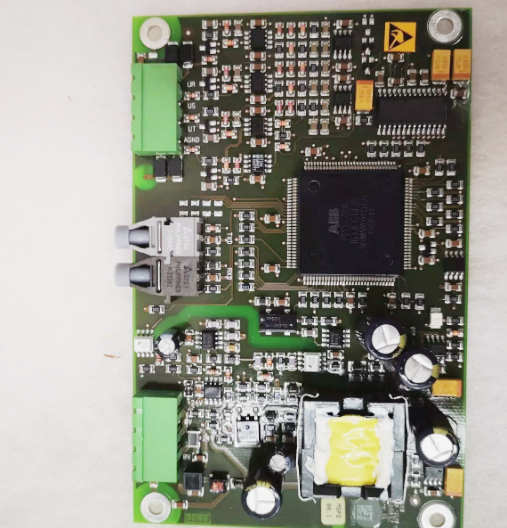

At a municipal wastewater treatment plant in Sweden, dual PM865AK01 controllers managed aeration basin DO control and sludge recirculation. During a lightning-induced surge, the primary controller failed—but thanks to the XVC768102 modules interconnecting the pair via multimode fiber, the standby unit assumed control in < 100 ms, preventing anaerobic conditions that would have violated environmental discharge permits. The plant had operated continuously on this redundancy setup for over 12 years, underscoring the module’s long-term reliability. Parameter 表格 ⚠️ Important: Uses ST-style fiber connectors (not LC)—ensure patch cords match. Technical Principles and Innovative Values Innovation Point 1: Deterministic Memory Mirroring Over Dedicated Fiber Unlike Ethernet-based redundancy schemes, the XVC768102 uses a non-routable, point-to-point optical link exclusively for state synchronization—eliminating network congestion risks and ensuring deterministic timing. Innovation Point 2: Full Application State Transfer Synchronizes not only I/O images but also task execution pointers, alarm queues, historical buffers, and communication contexts—enabling truly transparent failover without logic restart. Innovation Point 3: EMI Immunity for Electrically Noisy Plants Fiber-optic isolation prevents ground loops and rejects interference from VFDs, switchgear, or welding equipment—critical in steel mills, substations, and marine applications. Innovation Point 4: Seamless Integration with Control Builder M Redundancy configuration is handled entirely in software—no DIP switches or jumpers. The system auto-detects sync status and logs switchover events in the audit trail. Application Cases and Industry Value In a Middle Eastern desalination plant, XVC768102 modules linked redundant PM866 controllers managing high-pressure RO pumps. During a scheduled maintenance test, engineers simulated a CPU failure and confirmed 92 ms switchover with zero disruption to membrane pressure control—avoiding costly membrane damage. The plant has since standardized on this architecture across all six production trains. Similarly, at a U.S. hydroelectric dam, the XVC768102’s immunity to lightning-induced transients ensured continuous gate position control during monsoon season—where copper-based sync links had previously caused unexplained controller resets. Related Product Combination Solutions PM865AK01: Primary redundant AC 800M CPU (dual-core, 180 MHz) PM866AK01: Higher-performance CPU with extended memory TB850: Redundant I/O baseplate with dual CPU slots AI810 / AO810: Analog I/O modules for process control DI810 / DO810: Digital I/O for discrete signals CI854A: PROFIBUS DP communication interface PFSK151: 5 A redundant power supply for TB850 chassis 3BHE019719R0101 (PFSK152): 10 A power supply for higher loads This combination forms a complete, field-proven high-availability control system for legacy and mid-life-cycle installations. Installation, Maintenance, and Full-Cycle Support Installation Guidelines: Install one XVC768102 in each redundant CPU’s designated sync slot Connect via duplex multimode ST-ST fiber patch cord (OM1 or OM2 recommended) Ensure fiber end-faces are clean and free of scratches No IP address or software configuration needed for the module itself Maintenance Notes: Hot-swap capable—replace without powering down the system Monitor SYNC LED: steady green = normal; blinking red = fiber fault or mismatch Verify optical power levels if sync errors occur (> -22 dBm recommended)

We rigorously test every 3BHB007211R102 unit for:

Optical transmit/receive performance (per IEC 61280-4-2)

72-hour thermal stress (0°C ↔ 60°C)

Failover timing validation with PM865 under full load

Compatibility with firmware versions v2.1 through v3.3

All units are new surplus or factory-new stock, fully traceable, and backed by a 12-month warranty. We also provide migration path guidance to UFC770/XVC779102 platforms when modernization is planned.

Contact us for immediate delivery of XVC768102 (3BHB007211R102)—whether you’re maintaining a critical legacy system, replacing a failed unit, or building a spares inventory for long-life infrastructure. With decades of proven service in the world’s most demanding plants, this module remains a cornerstone of ABB’s high-availability legacy.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)