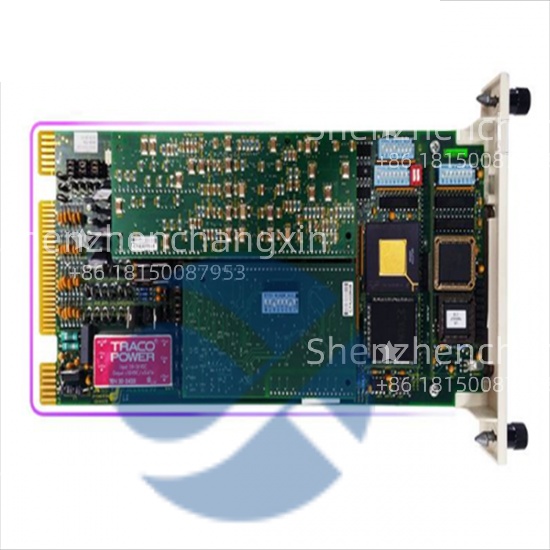

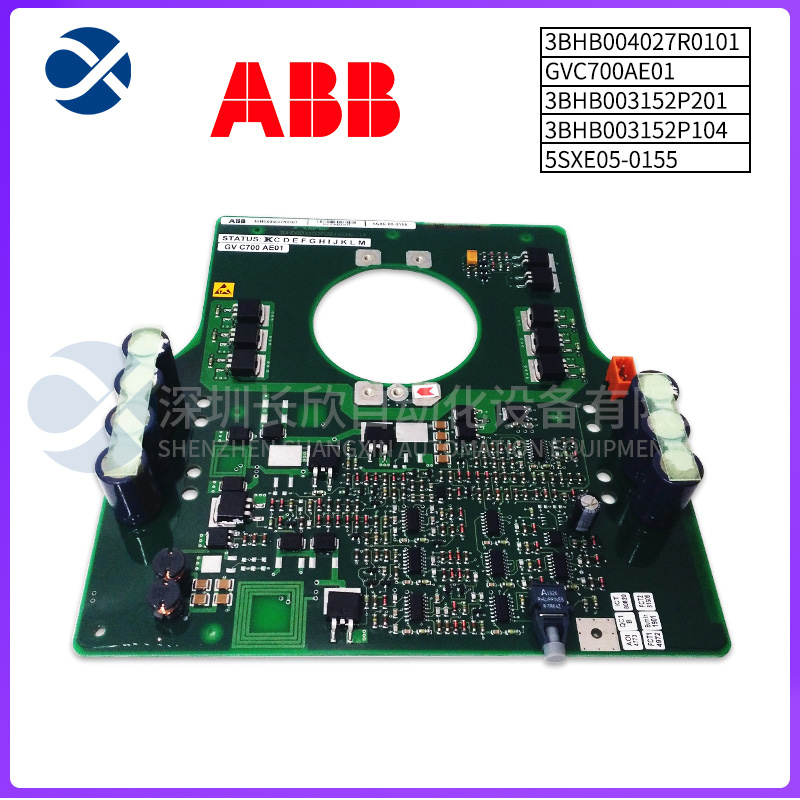

Description

Application Scenarios

Application Scenarios

At a steel rolling mill in Brazil,frequent inverter failures were causing unplanned downtime during hot rolling operations.The root cause was traced to degraded gate driver signals leading to IGBT shoot-through and module burnout.Maintenance engineers replaced the faulty control boards with the ABB UFC762AE101 3BHE006412R0101 Inverter Circuit Board,which restored precise timing and isolation in the drive’s PWM signals.Since the upgrade,the drives have operated without failure for over 18 months,even under high-temperature and high-vibration conditions.The board’s robust optocouplers and reinforced power regulation proved essential in stabilizing motor control during peak load cycles.

Parameter

Main Parameters Value/Description

Product Model ABB UFC762AE101 3BHE006412R0101

Manufacturer ASEA Brown Boveri(ABB)

Product Category Inverter Control Circuit Board/Gate Driver PCB

Function PWM Signal Generation,IGBT Gate Driving,Feedback Monitoring

Compatible Drive Series ABB ACS600,ACS800,Symphony Drive Modules

Input Control Signals 24 V DC(TTL/Logic Level),Fieldbus Interface(Optional)

Output Drive Signal±15 V to+20 V(IGBT Gate Drive)

Switching Frequency Up to 16 kHz(Adjustable via Software)

Isolation Type Optical Isolation(High-Voltage Barriers)

Protection Features Overcurrent,Short-Circuit,Overtemperature,DC Bus Monitoring

Feedback Signals Current Sensing(Analog),Temperature(Thermistor),Voltage Feedback

Operating Temperature-10°C to+70°C

Storage Temperature-25°C to+85°C

Installation DIN Rail or Chassis Mount(Drive Cabinet Compatible)

Compliance IEC 61800-5,IEC 61010,CE Marked

Note:”3BHE006412R0101″is the ABB part number,while”UFC762AE101″may refer to a functional or revision identifier.This PCB is typically used in conjunction with power stack modules like ABB AGDD-01 or similar.

Technical Principles and Innovative Values

Innovation Point 1:The ABB UFC762AE101 3BHE006412R0101 employs high-speed optocouplers and isolated DC-DC converters to ensure galvanic isolation between low-voltage control circuits and high-power IGBT stages,enhancing safety and noise immunity.

Innovation Point 2:Advanced PWM modulation algorithms are embedded in onboard logic or microcontroller,enabling smooth motor startup,reduced torque ripple,and energy-efficient operation.

Innovation Point 3:Integrated real-time fault detection circuitry monitors DC bus voltage,phase current,and heatsink temperature,triggering protective shutdowns within microseconds to prevent catastrophic drive failure.

Innovation Point 4:Designed for modular replacement,this PCB allows quick field service without removing the entire drive unit—minimizing downtime in production environments.

Innovation Point 5:High-density multilayer PCB layout with thermal vias and EMI shielding ensures signal integrity and long-term reliability under electrical stress and thermal cycling.

Application Cases and Industry Value

In a wastewater treatment plant in Canada,aging inverter boards caused frequent tripping of large submersible pumps.After installing the ABB UFC762AE101 3BHE006412R0101 as a replacement,the drives operated with improved stability and reduced harmonic distortion.Operators reported a 30%decrease in maintenance calls related to drive faults,and energy consumption dropped slightly due to optimized switching patterns.

At an automotive assembly line in Germany,robotic arm drives were experiencing synchronization issues due to inconsistent PWM signals.Engineers upgraded to the ABB UFC762AE101 3BHE006412R0101 board across multiple servo drives,resulting in smoother motion control and zero positioning errors over six months.The board’s precise timing and low jitter characteristics were critical in maintaining production line accuracy.

Related Product Combination Solutions

ABB ACS800-01/04/10:Drive units where the UFC762AE101 3BHE006412R0101 is commonly used as the main control board.

ABB AGDD-01/AGDR-01:IGBT power modules driven by this circuit board.

ABB RDCU-12/13:External I/O and communication units that interface with the inverter board.

ABB CP571/DriveWindow:Software tools for parameter tuning,diagnostics,and firmware updates.

ABB M3BP Series Motors:High-efficiency motors controlled via drives using this PCB.

ABB UN0820B-P HIER460385-R1:Power distribution board that supplies clean 24V DC to the inverter control section.

ABB 3BHE006412R0080:Earlier revision of the same inverter control board(compatible with proper firmware).

ABB Surge Protection Modules(e.g.,OVR series):Used upstream to protect the sensitive control board from voltage transients.

Installation,Maintenance,and Full-Cycle Support

To install the ABB UFC762AE101 3BHE006412R0101 Inverter Circuit Board,first de-energize the drive and discharge the DC bus.Remove the old board,ensuring ESD precautions are followed.Insert the new PCB into the backplane or connector,secure with screws,and reconnect fiber-optic or ribbon cables for gate signals and feedback.Power up and perform a self-test via the drive’s HMI or software.Green status LEDs indicate normal operation;error codes should be cleared and monitored.

Routine maintenance includes visual inspection for burnt components,capacitor bulging,or dust accumulation.Clean with compressed air and isopropyl alcohol if necessary.The board should be replaced as a complete unit—onboard component repair is not recommended due to precision calibration requirements.

We provide full lifecycle support,including technical documentation,firmware compatibility checks,burn-in testing,and access to certified refurbished units.Whether for emergency replacement or system modernization,our team ensures seamless integration of the ABB UFC762AE101 3BHE006412R0101 into your automation infrastructure.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: