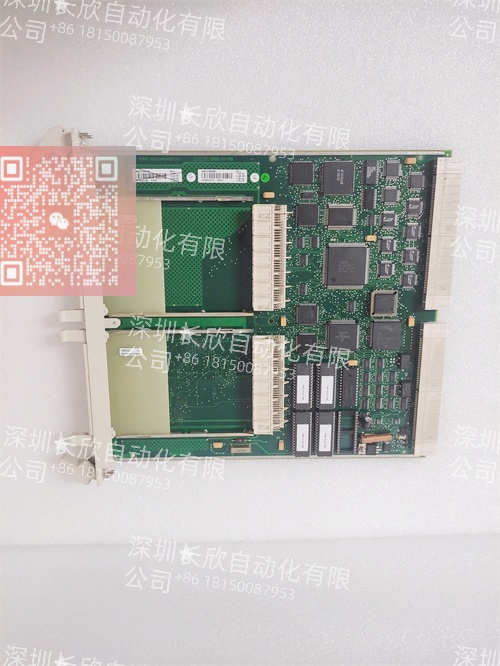

Description

Application Scenarios

In a pharmaceutical bioreactor, maintaining precise control over temperature, pH, dissolved oxygen, and pressure is critical for product quality and batch consistency. Each of these parameters is measured by sensitive analog sensors outputting 4-20 mA signals. Signal integrity is paramount; any noise, cross-talk, or drift can lead to incorrect control actions, ruining an entire batch worth millions. The process engineer selected the ABB SC540 3BSE006096R1 modules for the reactor’s control cabinet. Each SC540 accurately digitizes signals from eight critical sensors. Its high channel-to-channel isolation prevented signals from the powerful agitator motor drives from interfering with the sensitive pH probe readings. The module’s high resolution allowed the control system to detect minute changes in process variables, enabling tighter control loops. The engineer noted that the consistent, reliable data from the SC540 was foundational for achieving regulatory compliance (FDA 21 CFR Part 11) for data integrity and ensuring repeatable, high-yield production.

Technical Principles and Innovative Values

Innovation Point 1: High-Density Design with Superior Signal Integrity. The ABB SC540 3BSE006096R1 packs eight isolated analog input channels into a single, compact module. Each channel features individual signal conditioning and analog-to-digital conversion, coupled with high-grade isolation barriers. This design critically eliminates ground loops and prevents noise or faults on one channel (e.g., a faulty transmitter) from affecting the readings on adjacent channels, ensuring the purity and reliability of each individual measurement in electrically noisy plant environments.

Innovation Point 2: Universal Input Flexibility and Intelligent Diagnostics. A key advantage is its software-configurable input type per channel. Engineers can wire different sensor types (current, voltage, RTD) to the same module and configure each channel individually via the control system software. This simplifies design, reduces spare part variety, and allows for easy system modifications. Furthermore, the module incorporates advanced diagnostics, continuously monitoring for open circuits, short circuits, and signal values outside configured ranges, enabling predictive maintenance and immediate fault identification.

Innovation Point 3: Hot-Swappable for Maximum Process Availability. As a core component of the S800 I/O system, the SC540 supports true hot-swapping in redundant configurations. If a module fails or needs replacement, it can be safely removed and a new one inserted without shutting down the controller or stopping the process. The system automatically recognizes the new SC540. downloads its configuration, and brings it online. This feature is indispensable for continuous processes in industries like oil & gas or chemicals, where unplanned downtime is extremely costly.

Application Cases and Industry Value

Case Study: Optimizing Energy Consumption in a District Heating Plant.

A municipal district heating plant needed to accurately measure the flow and temperature at dozens of heat exchanger stations and substations to bill customers fairly and optimize boiler output. Their existing analog input system suffered from drift and required frequent manual calibration, leading to billing inaccuracies and energy waste.

Solution & Implementation: The plant upgraded its SCADA system and installed remote I/O stations based on the S800 platform. Each station used ABB SC540 3BSE006096R1 modules to connect to 4-20 mA signals from temperature transmitters (Pt100 with transmitters) and electromagnetic flow meters. The high accuracy and long-term stability of the SC540 modules eliminated measurement drift.

Outcome and Value: Billing accuracy improved by 5%, directly increasing revenue. More importantly, the reliable, high-resolution data from the SC540 modules allowed the control system to implement advanced optimization algorithms. The plant could now precisely match heat supply to real-time demand, reducing natural gas consumption by 12% annually. Maintenance costs plummeted as the need for routine field calibration was drastically reduced. The plant manager cited the SC540 as the “trusted sense organ” of the new efficiency drive.

Related Product Combination Solutions

ABB S800 Base Units (e.g., SD831): The base unit that provides the physical mounting, terminal connections, and internal bus communication for the SC540 module. The correct base unit must be selected to match the signal type (e.g., current/voltage).

ABB SB510 Signal Biasing Module: A supplementary module used in conjunction with the SC540 when measuring signals from sensors that require a supply voltage, such as potentiometers or certain transmitters.

ABB AI810 Analog Input Module: Another 8-channel analog input module in the S800 family, often used in similar applications; selection between SC540 and AI810 may depend on specific system generation or performance requirements.

ABB SC510 Digital Input Module: A complementary digital input module used in the same I/O station to acquire discrete status signals (e.g., pump run, valve limit) alongside the analog process values from the SC540.

ABB CI871 PROFIBUS Communication Interface: Allows a station containing SC540 and other I/O modules to connect as a slave to a PROFIBUS DP network, making the analog data available to a wide range of PLCs.

ABB AC 800M Controller (e.g., PM803F): The high-performance controller that processes the analog data from the SC540. running control algorithms and logic.

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB SC540 3BSE006096R1 is modular. The module is simply pressed into its designated slot on the compatible S800 base unit (e.g., SD831). All field wiring for the analog sensors is connected to the terminal blocks on the base unit, ensuring clear separation and easy access. Configuration is performed entirely within the control system engineering software (e.g., Control Builder). Here, each channel is configured for its specific signal type (e.g., 4-20mA), scaling, filter time, and alarm limits. The software also handles the calibration of the module’s analog-to-digital converter if high precision is required.

Routine maintenance is minimal. The primary task is to utilize the module’s diagnostic capabilities proactively. The control system can be programmed to alert personnel to trends like increasing signal noise or minor drift. The hot-swap capability is the key maintenance feature. In the event of a module failure indicated by diagnostics, a technician can safely replace the SC540 without a system shutdown, minimizing process impact. Keeping a pre-configured spare module on-site is a best practice for critical loops.

We provide comprehensive lifecycle support for the ABB SC540 3BSE006096R1 and the entire S800 I/O system. We supply 100% authentic, factory-tested modules with full documentation. Our technical support can assist with base unit selection, configuration advice for different sensor types, and best practices for wiring and grounding to maximize signal integrity. We understand that accurate measurement is the foundation of effective control, and we are committed to providing the reliable components and expertise to support your automation goals.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: