Description

Application Scenarios

Application Scenarios

Consider the critical generator in a large hydropower plant, a multi-million dollar asset whose failure would mean catastrophic financial loss and widespread power outages. The most feared event is an internal fault, like a turn-to-turn short within the stator winding, which can rapidly escalate into a fire. The ABB DI93A HESG440355R3 is the first line of defense. It continuously monitors the current entering and leaving the protected zone (e.g., both ends of the generator stator). Under normal conditions, these currents are equal. The moment an internal fault occurs, this balance is violently disrupted. The DI93A detects this differential current with exceptional speed and certainty. Its sophisticated high-impedance design makes it inherently stable during severe external faults that could saturate current transformers, preventing a false, catastrophic trip. When a genuine internal fault is confirmed, it sends a definitive trip command to the circuit breaker in milliseconds, isolating the generator before significant damage occurs. This direct protection of the core asset addresses the paramount pain points of maximizing equipment lifespan, preventing unplanned outages, and ensuring grid stability.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: High-Impedance Principle for Unmatched Stability. Unlike low-impedance relays, the ABB DI93A HESG440355R3 employs a high-impedance circulating current principle. It connects a high-value stabilizing resistor in series with a voltage-sensitive operating element. During an external fault, even if one CT saturates, the high impedance limits the spill current through the operating circuit to a negligible level. This makes the relay exceptionally secure against false tripping—a critical advantage when protecting expensive apparatus where an unnecessary outage is extremely costly.

Innovation Point 2: Extreme Speed for Damage Limitation. The relay is designed for minimum operating time, often clearing faults within one power cycle (<20ms). This speed is not merely a specification; it directly correlates to reduced damage. For a generator fault, the energy released is proportional to the square of the fault duration. By clearing the fault in 20ms instead of 200ms, the DI93A can reduce thermal and mechanical stress by a factor of 100. potentially turning a catastrophic rewind into a minor repair. This speed is achieved through a simple, robust analog measurement circuit that avoids complex digital processing delays.

Innovation Point 3: Certified Reliability for Safety-Critical Systems. The DI93A is designed and certified for use in high-integrity protection schemes, including those requiring Safety Integrity Level (SIL) 3 certification according to IEC 61508. Its design simplicity, with minimal components and a proven operating principle, contributes to a high diagnostic coverage and a very low probability of failure on demand. This makes it a trusted choice not just for asset protection, but also for personnel and process safety in the most demanding industrial environments.

Application Cases and Industry Value

Case Study: Steel Mill Synchronous Motor Protection. A major steel mill experienced repeated, unexplained outages on a critical 20MW synchronous motor driving a hot strip mill fan. The existing overcurrent protection was not sensitive enough to detect incipient turn-to-turn faults, which escalated into major ground faults causing weeks of downtime. Engineers installed an ABB DI93A HESG440355R3 for dedicated stator differential protection. During commissioning, a simulated internal fault test showed the DI93A operated in 18ms. Months later, it detected a genuine phase-to-phase fault during startup and cleared it before the backup protection even registered the event. The mill’s electrical superintendent reported: “The DI93A gave us the sensitivity and speed we needed. It prevented what would have been a complete stator burnout, saving over $500.000 in repair costs and three weeks of production loss.”

Case Study: Data Center Mission-Critical Bus Protection. A hyperscale data center required absolute power continuity for its 20kV medium-voltage switchgear. The main busbar, connecting multiple transformers and generators, needed fast and absolutely secure protection. A low-impedance differential scheme was considered but deemed vulnerable to CT saturation during external faults. The solution was a high-impedance scheme using multiple ABB DI93A HESG440355R3 relays. Their inherent stability during through-faults provided the required security, while their speed ensured selective isolation. During a real-world cable fault on a feeder, the relevant feeder protection cleared the fault correctly. The DI93A relays monitoring the main bus remained perfectly stable, preventing a total site blackout. The consulting engineer stated, “For busbar protection, security is even more important than speed. The DI93A’s high-impedance design gave us that confidence.”

Related Product Combination Solutions

ABB REF615: A versatile feeder protection and control IED. The REF615 can provide comprehensive backup protection (overcurrent, earth fault) for the same generator or feeder, while the DI93A provides the primary, high-speed differential protection.

ABB REG216: A dedicated generator protection relay. In a complete generator protection panel, the REG216 handles all other functions (loss of excitation, negative sequence, voltage protection), with the DI93A HESG440355R3 providing the core, high-speed stator differential (87G) function.

ABB RET670: A advanced transformer and bay controller. For transformer differential protection, the RET670 might be used, while the DI93A could be applied for busbar or short line protection within the same substation, offering a complementary, high-security solution.

ABB REB500: A modern busbar protection system. For larger, more complex busbar configurations, the REB500 system would be used, while the DI93A remains ideal for simpler, single-zone busbars or critical apparatus protection.

ABB COMBIFLEX Test Plug: This test block system is essential for the safe isolation and testing of relays like the DI93A without disconnecting the critical CT circuits, enabling routine maintenance without system shutdown.

ABB Injection Test Set (e.g., Freja 500): A modern secondary injection test system used to verify the operating characteristics, timing, and stability of the DI93A during commissioning and periodic maintenance.

ABB CTs (Class PX/TPX): Specially characterized Current Transformers are mandatory for a high-impedance differential scheme. Their knee-point voltage and resistance must be carefully matched to the DI93A settings for correct operation.

ABB Stabilizing Resistor (External): A precisely calculated external resistor is a key component of the scheme, determining the relay’s stability voltage. It is always supplied and sized as part of the complete DI93A protection package.

Installation, Maintenance, and Full-Cycle Support

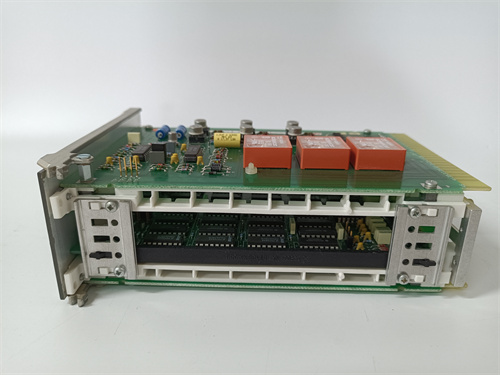

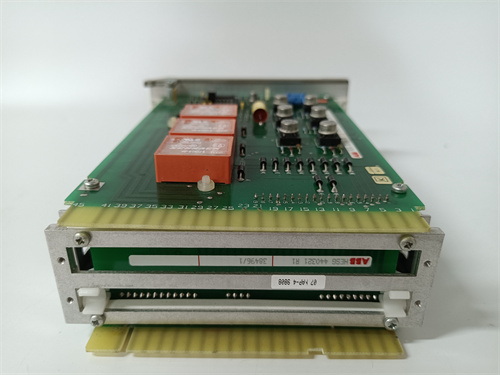

Installation and commissioning of the ABB DI93A HESG440355R3 require expertise in protection engineering. The core task is the correct connection of current transformers (CTs) from all ends of the protected zone to the relay. CTs must be identical and of high quality, typically Class PX. A critical external component is the stabilizing resistor, which must be calculated based on the CT parameters, lead resistance, and the desired operating voltage. The relay itself is panel-mounted, and its output contacts are wired to the trip circuit of the associated circuit breaker(s). Rigorous secondary injection testing is mandatory to verify the relay’s actual operating current, stability voltage, and timing match the protection study settings, ensuring the scheme will operate correctly and securely.

Routine maintenance is straightforward but vital. It involves periodic secondary injection tests as per the plant’s protection maintenance schedule to verify settings and operating time. Visual inspections for loose connections and monitoring of the relay’s health indicators are also standard. Due to its critical function, a “defense-in-depth” approach is common, where the DI93A serves as the primary protection, with a separate relay (like a REF615) providing backup. A spare relay, pre-configured and tested, is often kept on-site. Should a fault be suspected, the entire DI93A unit can be replaced quickly, and the original unit sent for detailed bench testing and repair.

We provide comprehensive, full-cycle support for the ABB DI93A HESG440355R3. This includes supplying genuine relays, performing setting calculations, and designing complete protection schemes with stabilizing resistors and metrosils. Our technical support can assist with scheme design reviews, coordination studies, and on-site commissioning support. We understand that differential protection is the cornerstone of electrical system security and are committed to providing the products, expertise, and rapid spare parts service needed to ensure the reliability and safety of your most critical assets.

Secure the heart of your electrical system with uncompromising protection. Contact us for the ABB DI93A HESG440355R3 and expert application engineering support.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email:

.jpg)