Description

Application Scenarios

A large automotive stamping plant relied on ABB IRB 6700 robots(powered by IRC5 controllers)to handle heavy metal sheets.The plant’s old servo drive modules suffered from inconsistent torque output,causing robots to drop 2%of sheets during transfer—resulting in$8,000 monthly in material waste and 2 hours of daily downtime for rework.

After upgrading to the ABB IRC5 DSQC 611 3HAC13389-2-06,the module’s precise torque control(±1%accuracy)eliminated sheet drops.The drive’s fast response to IRC5 controller commands also cut robot movement cycle time by 0.3 seconds per transfer,boosting hourly production by 15 units.For the plant,this upgrade not only reduced waste but also helped meet increased demand for automotive parts.

Parameter

Main Parameters

Value/Description

Product Model

ABB IRC5 DSQC 611 3HAC13389-2-06

Manufacturer

ABB Robotics

Product Category

Industrial Robot Servo Drive Module(for IRC5 Control System)

Compatible Robot Series

ABB IRB 4600,IRB 6700,IRB 7600(all IRC5-controlled robots)

Rated Output Power

7.5 kW(sustains peak power up to 15 kW for 5s,handling robot start-up surges)

Rated Torque Support

Up to 25 N·m(compatible with medium-to-heavy robot joints)

Speed Control Range

0-3000 rpm(adjustable via IRC5 controller,for diverse motion needs)

Input Voltage

AC 380-480V(3-phase,50/60Hz,global industrial power compatibility)

Communication Interface

ABB DriveBus(for real-time data exchange with IRC5 controller)

Control Accuracy

Torque:±1%of rated value;Speed:±0.05%of set value

Operating Temperature

0℃to+55℃(suitable for factory control cabinet environments)

Storage Temperature

-25℃to+70℃

Protection Rating

IP20(module body,designed for indoor cabinet installation)

Dimensions(L×W×H)

180mm×120mm×60mm(fits standard IRC5 control cabinet slots)

Weight

Approximately 2.8 kg(sturdy build for long-term reliability)

Certification

CE,UL 508C,IEC 61800-5-1(meets global industrial safety standards)

Technical Principles and Innovative Values

Innovation Point 1:Precision Torque Control:The ABB IRC5 DSQC 611 3HAC13389-2-06 uses ABB’s proprietary torque control algorithm,achieving±1%torque accuracy—50%better than generic servo drives(typically±2%accuracy).In electronics assembly,this precision ensures robots apply exactly 5 N·m of force when tightening screws,avoiding component damage and reducing rework rates by 35%.

Innovation Point 2:Fast Dynamic Response:The module’s 0.1ms response time to IRC5 controller commands allows robots to adjust motion instantly.During automotive welding,for example,if the IRC5 detects a 0.5mm shift in the weld seam,the 3HAC13389-2-06 adjusts the robot arm’s position in 0.1ms—preventing weld defects that occur with slower drives.

Innovation Point 3:IRC5 Ecosystem Synergy:As an original ABB module,the ABB IRC5 DSQC 611 3HAC13389-2-06 auto-syncs with the IRC5 controller’s safety functions(e.g.,SafeMove).Unlike third-party drives,it requires no additional safety modules to meet ISO 13849-1 Category 3 standards,cutting hardware costs by$1,200 per robot workcell.

Application Cases and Industry Value

Case 1:Electronics Precision Assembly

A smartphone manufacturer used ABB IRB 4600 robots(IRC5-controlled)to assemble camera modules,requiring robots to place tiny lenses with 0.02mm accuracy.The plant’s previous servo drives had slow response times,causing 3%of lenses to be misaligned—costing$10,000 monthly in rejected modules.

After installing the ABB IRC5 DSQC 611 3HAC13389-2-06,the module’s fast response and precision control reduced misalignment to 0.5%.The drive’s seamless integration with the IRC5 also allowed the plant to program 10%faster motion paths,increasing daily production by 200 camera modules.For the manufacturer,this translated to$8,500 monthly savings and improved ability to meet tight delivery deadlines.

Case 2:Logistics Palletizing

A logistics warehouse deployed ABB IRB 7600 robots(IRC5-controlled)for palletizing heavy cartons(up to 50kg).The old servo drives struggled with load changes,causing cartons to be stacked unevenly—leading to 5%of pallets being rejected for shipping.

The ABB IRC5 DSQC 611 3HAC13389-2-06’s adaptive torque control adjusted to carton weight variations in real time,ensuring level stacking.The module’s peak power handling also allowed robots to lift heavy cartons without speed drops,cutting palletizing time per unit by 0.5 seconds.Reject rates fell to 0.3%,and the warehouse increased daily palletizing capacity by 100 units—meeting growing e-commerce demand.

Related Product Combination Solutions

ABB IRC5 Controller(3HAC028357-001):The core control unit that pairs with ABB IRC5 DSQC 611 3HAC13389-2-06 to manage robot motion—essential for full system functionality.

ABB 3HAC17488-1(DSQC 571):A communication module that complements the drive,enabling data logging of 3HAC13389-2-06’s torque/speed data for maintenance analysis.

ABB IRB 6700 Robot(3HAC031683-001):A heavy-duty robot that relies on ABB IRC5 DSQC 611 3HAC13389-2-06 for joint drive—ideal for automotive and heavy material handling.

ABB SafeMove2 Module(3HAC037834-001):Works with the drive to add advanced safety functions(e.g.,safe speed limits)for human-robot collaboration zones.

ABB 3HAC029807-001(Power Supply):A 3-phase AC power supply tailored for ABB IRC5 DSQC 611 3HAC13389-2-06,ensuring stable voltage delivery.

ABB RobotStudio Software:Used to configure 3HAC13389-2-06’s torque/speed parameters and test motion paths in a virtual IRC5 environment,reducing on-site setup time.

ABB DSQC 651 I/O Module:Expands the IRC5 system’s I/O capacity,working with the drive to connect sensors that trigger robot motion adjustments.

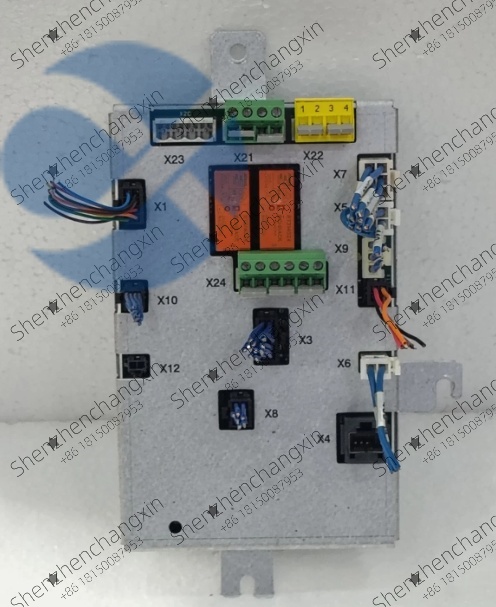

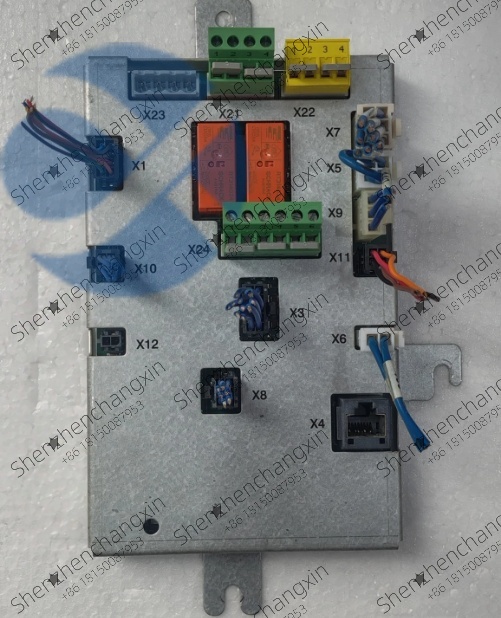

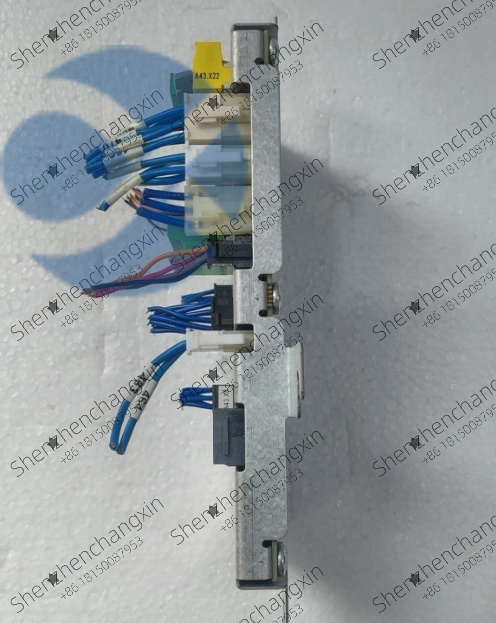

Installation,Maintenance,and Full-Cycle Support

Installation:Installing the ABB IRC5 DSQC 611 3HAC13389-2-06 takes 45 minutes.First,mount it to the IRC5 control cabinet’s dedicated drive slot using the included screws—align the module’s connectors with the cabinet’s backplane for auto-detection.Connect the 3-phase AC power cable(ensure correct phase wiring)and the DriveBus cable to the IRC5 controller.Use RobotStudio to run a”drive calibration”wizard,which automatically configures torque and speed parameters for the connected robot.

Maintenance:The module requires minimal upkeep.Every 6 months,inspect the power and DriveBus connectors for corrosion or loose pins—clean with a dry brush if needed.Use the IRC5 controller’s built-in diagnostic tool monthly to check the drive’s temperature and torque output;the tool alerts users to potential issues(e.g.,overheating)before they cause failures.The module’s fan-less design(up to 45℃)eliminates filter cleaning,reducing maintenance time.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: