Description

Application Scenarios

At a combined-cycle power plant in the Middle East, engineers needed to upgrade their legacy mechanical overspeed trip system to a fully integrated, auditable digital solution compliant with IEC 61511. The new design required a safety output capable of de-energizing two independent fuel valve solenoids within 100 ms of a turbine overspeed event—while proving channel health during every startup. The ABB DSSR122 4899001-NK was selected for its dual force-guided relays, built-in test pulse functionality, and native integration with the AC 800F-based SIS. During commissioning, the module’s feedback monitoring confirmed correct wiring and contact status before each run. Over 18 months of operation, it executed three successful emergency trips—all logged with millisecond precision in 800xA—and passed every third-party SIL audit without deviation. The DSSR122 4899001-NK became the trusted final link between logic solver and physical safety action.

Technical Principles and Innovative Values

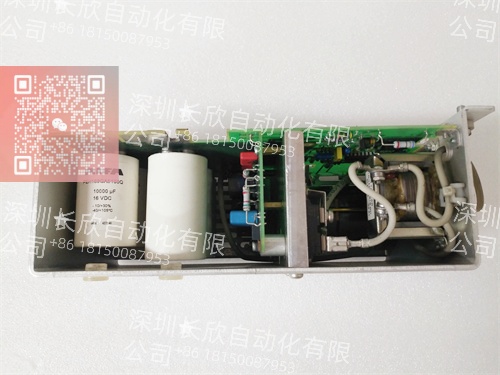

Innovation Point 1: Force-guided relay contacts mechanically link NO and NC contacts—ensuring that if one welds shut, the other cannot falsely indicate a safe state. This meets strict requirements for SIL 3 final element control.

Innovation Point 2: Integrated test pulse and feedback loop allows the controller to verify relay coil integrity and field wiring continuity before and after every safety demand—eliminating latent faults that could cause dangerous failure on demand.

Innovation Point 3: Dual independent channels enable flexible safety architectures: both can drive separate solenoids for redundancy, or be wired in series for higher reliability in single-valve applications.

Innovation Point 4: Seamless integration with ABB 800xA SIS provides full asset visibility—relay status, diagnostic alarms, and trip history appear alongside process data, simplifying compliance reporting and root-cause analysis.

Application Cases and Industry Value

In a North Sea offshore platform, a gas compressor train required a SIL 3 shutdown system to isolate hydrocarbons during fire or overspeed events. Legacy relays lacked diagnostics, leading to frequent false trips and manual testing downtime. After installing ABB DSSR122 4899001-NK modules, the platform achieved continuous online proof testing: every 8 hours, the system auto-verified relay health without interrupting production. During an actual fire alarm, both channels de-energized within 8 ms, closing dual block valves and preventing escalation. The incident report—automatically generated by 800xA—showed zero relay anomalies, satisfying HSE regulators and avoiding a $ 5M/day production suspension. The DSSR122 delivered both safety and operational continuity.

Related Product Combination Solutions

ABB AC 800F CPU (e.g., PM802F): Safety-rated controller that drives DSSR122 4899001-NK with certified firmware.

ABB CI854A 3BSE020510R1: Redundant communication module for secure SIS data exchange with 800xA.

ABB DSTP012 4899001-NH: Safety digital input module—pairs with DSSR122 for complete SIS I/O.

ABB 800xA System with SIS Extension: Unified engineering and operations environment for safety logic configuration and event logging.

ABB Turbine Protection System (TPS): Pre-engineered solution using DSSR122 for steam/gas turbine emergency trips.

ABB FSOE (Fail Safe over EtherCAT) or PROFIsafe Interfaces: For modern safety networks where DSSR122 acts as local relay output.

ABB Solenoid Valves (e.g., Neles or Masoneilan): Final elements directly controlled by DSSR122’s force-guided contacts.

Installation, Maintenance, and Full-Cycle Support

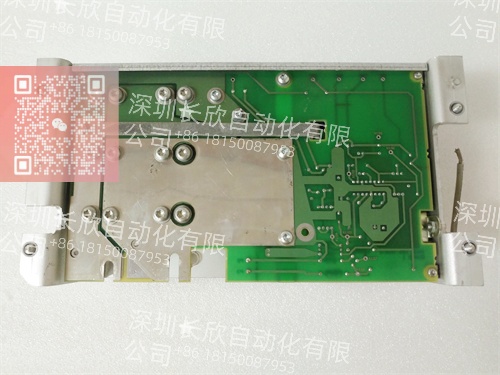

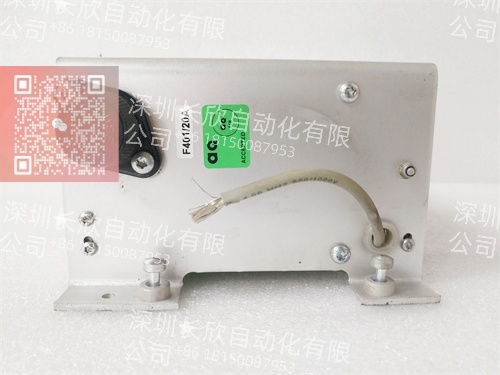

Installing the ABB DSSR122 4899001-NK requires connecting field devices (e.g., trip solenoids) to its screw terminals and linking feedback wires to confirm contact position. The module draws power and control signals from the AC 800F backplane—no external supply needed. Wiring must follow separation rules for safety circuits (IEC 61511 Annex F).

Maintenance is minimized through continuous diagnostics: the controller periodically sends a low-energy test pulse to verify coil resistance and detect open/short circuits. Any anomaly triggers a “Channel Fault” alarm in 800xA, allowing repair during planned outages. The module’s LEDs provide instant visual status—green for healthy, red for fault—even without system access. Our certified engineers provide SIL verification documentation, loop validation reports, and periodic functional safety assessments throughout the lifecycle. Every DSSR122 4899001-NK is 100% tested for contact bounce, dielectric strength, and mechanical endurance to ensure decades of reliable service in life-critical applications.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: