Description

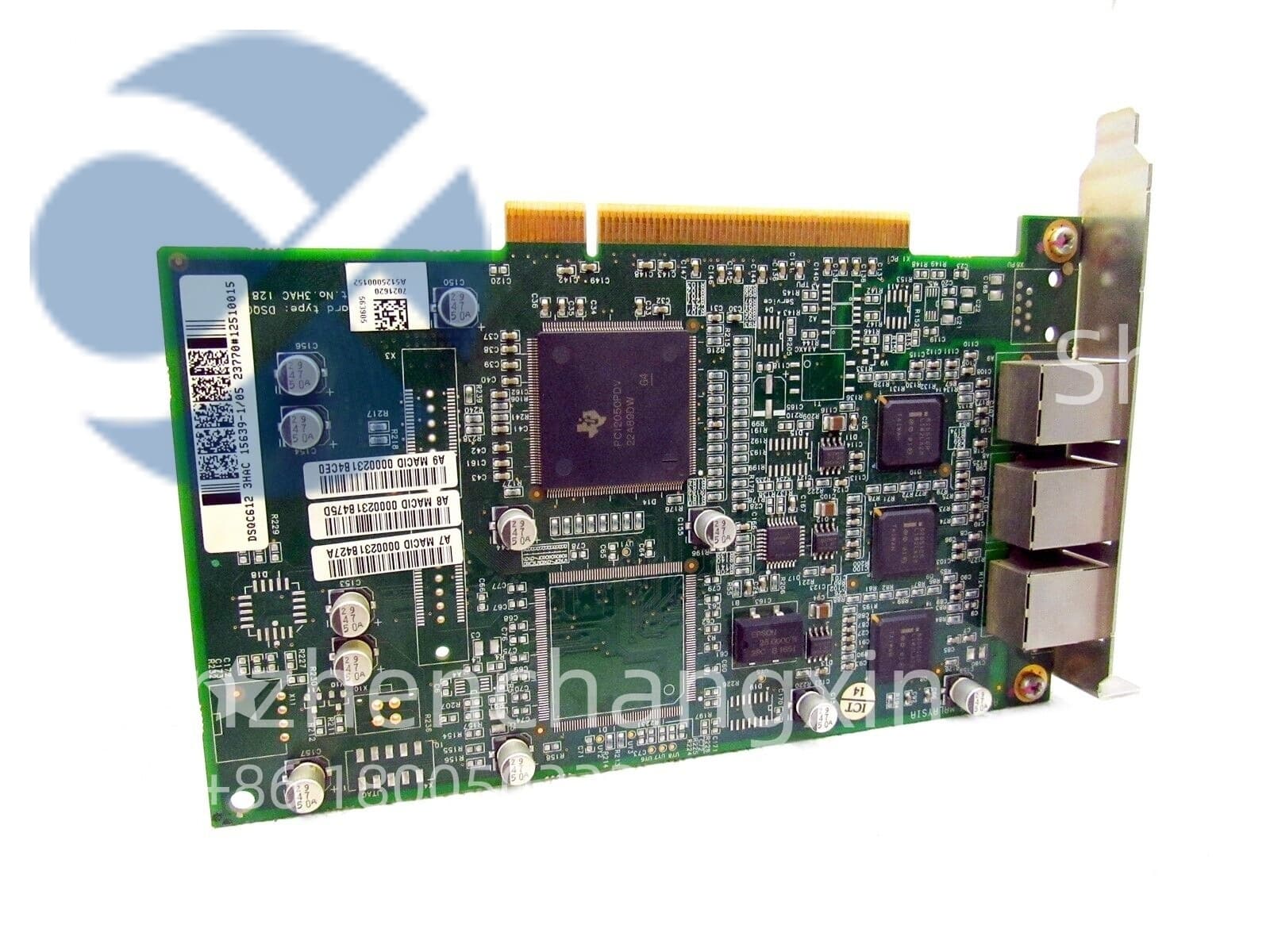

ABB DSQC612(3HAC15639-1)Product Overview In industrial robot systems,the IRC5 controller is the”command center,”and the ABB DSQC612(3HAC15639-1)is the”core brain”of this command center—the key circuit board responsible for translating the robot’s motion commands into actual control signals!Whether it’s a robot on an automotive welding line precisely aligning with solder joints,or an assembly robot in an electronics factory meticulously grasping parts as thin as 0.1mm,it relies on this circuit board to calculate motion trajectories and coordinate the movements of servo motors and I/O modules.Without it,the robot would be like a”headless fly,”unable to move at all.Those of us in robot maintenance know that the stability of the circuit board directly determines whether a robot can work,and the ABB DSQC612(3HAC15639-1)excels in this regard.The dual-power supply design(5V logic power+12V analog power)ensures that even with minor voltage fluctuations on one supply,the core circuitry can still operate normally on the other.Furthermore,it isolates analog and digital signals,making it less susceptible to interference from motors and voltage surges in the workshop.For example,a customer had a welding robot working next to a high-power welding machine;the ABB DSQC612(3HAC15639-1)still maintained welding accuracy within 0.2mm,significantly more stable than other brands of robots in the same workshop.Even more conveniently,this board is compatible with all IRC5 controllers,from older IRC5 Single models to newer IRC5 Compact models.Simply remove the old board,insert the ABB DSQC612(3HAC15639-1),and re-flash the firmware to use it.A customer’s robot,used for 8 years,frequently reported faults on its old circuit board.After replacing it with an ABB DSQC612(3HAC15639-1),not only did the faults disappear,but the robot’s motion response also improved by 10%.ABB’s original circuit boards truly offer reliable performance!Key Features and Advantages:Precise Motion Control,Robot”Mill-Sized”:The ABB DSQC612(3HAC15639-1)features a built-in high-precision motion control chip capable of calculating motion trajectories at the 0.01mm level.Combined with ABB’s servo drive system,the robot’s repeatability can reach±0.05mm.Previously,an automotive parts customer used it with a welding robot to weld 2mm thin steel plates.The robot’s welding torch positioning error never exceeded 0.1mm,resulting in very smooth welds.The product qualification rate increased from 96%to 99.8%,significantly reducing rework costs.Moreover,it supports multi-axis linkage control,allowing 6-axis robots to move simultaneously without conflict,and it can handle complex curved surface welding.Stable and reliable,with very few faults:The ABB DSQC612(3HAC15639-1)boasts an MTBF exceeding 400,000 hours,equivalent to 45 years of continuous operation without failure,twice the lifespan of many third-party circuit boards.One electronics factory’s assembly robots operate 24/7,and the ABB DSQC612(3HAC15639-1)ran continuously for 6 years without a single circuit board failure,requiring only periodic dust removal maintenance.Furthermore,it has built-in fault diagnosis capabilities;if there are abnormal signals or unstable power supply,it will issue an early alarm in RobotStudio,preventing sudden shutdowns and allowing maintenance personnel to troubleshoot in advance,avoiding downtime losses.High compatibility,upgrades”without major modifications”:The ABB DSQC612(3HAC15639-1)is a”universal board”for IRC5 controllers.Regardless of the year the customer’s controller was purchased,as long as it’s an IRC5 series controller,it can be used immediately without changing the control cabinet or modifying the robot program.One customer,who was using a 2015 IRC5 Multimove controller and wanted to upgrade the robot’s control precision,purchased the ABB DSQC612(3HAC15639-1).The old board was removed,the new board installed,and the firmware flashed—all done in 2 hours,and production resumed the same day.If a different brand of board had been used,system adaptation would have been required,resulting in at least 3 days of downtime and prohibitively high costs.Strong anti-interference,”unrestricted by workshop environment”:Many interferences in industrial workshops?The ABB DSQC612(3HAC15639-1)is not afraid at all!It isolates analog circuits(such as servo signals)and digital circuits(such as logic signals)with 150V AC,so even if there are high-power motors or welding machines nearby,it will not affect the board’s operation;moreover,its power supply end has surge protection,so sudden voltage fluctuations in the workshop will not burn out the board.There is a robot in a metallurgical plant,installed not far from the blast furnace,where the voltage fluctuates frequently,but the ABB DSQC612(3HAC15639-1)still operates stably without ever experiencing a single misalignment due to interference.

English Version

The ABB DSQC612(3HAC15639-1)serves as the core motion control circuit board for ABB’s IRC5 robot controllers,playing a pivotal role in translating operational commands into precise robotic movements.Designed for industrial robotics applications—from automotive welding to electronic assembly—it excels in high-precision trajectory calculation,multi-axis coordination,and real-time signal processing,ensuring robots achieve repeatability of±0.05mm,a critical requirement for complex manufacturing tasks.

One of its standout strengths is exceptional reliability,with an MTBF of over 400,000 hours.This long-term stability minimizes unplanned downtime,a key concern for 24/7 production lines.For instance,an electronics manufacturer operating assembly robots continuously reported no board failures for six years,with only routine dust removal required for maintenance.The board’s built-in diagnostic capabilities further enhance uptime by alerting technicians to potential issues(e.g.,signal anomalies,power fluctuations)via RobotStudio,enabling proactive troubleshooting before breakdowns occur.

Seamless compatibility with all IRC5 controller variants(Compact,Single,Multimove)simplifies system upgrades.Unlike third-party alternatives that demand extensive reconfiguration or cabinet replacement,the ABB DSQC612(3HAC15639-1)can be installed and commissioned in just two hours—critical for minimizing production disruption.Its robust anti-interference design,including 150V AC isolation between analog and digital circuits,ensures stable performance even in harsh industrial environments with high electromagnetic noise(e.g.,near welding machines or large motors).

Engineered to operate within 0℃to 45℃and backed by ABB’s rigorous quality standards,the ABB DSQC612(3HAC15639-1)delivers consistent,high-performance control for robotic workstations.It supports advanced features like multi-axis synchronization and servo drive coordination,making it an ideal choice for manufacturers seeking to optimize Precision,reliability,and operational efficiency in robotic automation.Application Areas:Automotive Welding Industry:Robots in automotive welding workshops require extremely high welding precision.The ABB DSQC612(3HAC15639-1)is the”guarantee of precise control.”A certain automotive OEM used it with a 6-axis welding robot to weld 1mm thin steel plates on the car body frame.The board precisely calculates the welding torch trajectory,keeping the robot’s repeatability error within 0.08mm.This increased the weld bead qualification rate by 3.8%and reduced the rework rate from 4%to 0.2%,saving nearly 200,000 yuan in rework costs annually.Moreover,with 10 welding machines operating simultaneously in the workshop,the electromagnetic interference is strong.The ABB DSQC612(3HAC15639-1)withstood the interference through its isolation design,and there was not a single instance of welding torch misalignment.Electronics Assembly Industry:The assembly of micro-components in electronics factories(such as mobile phone camera modules)requires robots that”work like needles,”and the ABB DSQC612(3HAC15639-1)can meet this need.A mobile phone OEM factory uses it with a 4-axis assembly robot to grasp 0.5mm lens parts.The high-precision trajectory calculation of the circuit board ensures that the robot’s motion error is less than 0.05mm,increasing the part assembly yield from 97%to 99.7%,saving more than 500 lens parts per day.Moreover,it supports rapid response;the robot can complete 30 assembly actions per minute,a 15%increase in efficiency compared to using older circuit boards,resulting in a significant increase in production capacity.Logistics Sorting Industry:The rapid positioning and grasping of logistics robots also rely heavily on the control of the ABB DSQC612(3HAC15639-1).An e-commerce logistics center uses it in conjunction with AGV robots.The robots need to stop precisely in front of their designated locations on the sorting line(error≤10mm).The circuit board coordinates signals from servo motors and laser sensors to keep the robot’s stopping error within 5mm,reducing the sorting error rate from 0.8%to 0.1%,saving over 200 packages per day.Moreover,it supports 24-hour continuous operation,ensuring smooth operation of the sorting line even during peak logistics periods.In the metallurgical material handling industry:the high-temperature environment of metallurgical plants poses a challenge to robot circuit boards,but the ABB DSQC612(3HAC15639-1)can withstand it.A steel plant uses it in conjunction with handling robots to grasp high-temperature steel coils(the workshop temperature reaches a maximum of 42℃).The circuit board remains stable under high temperatures,with the robot’s grasping position error less than 2mm,and there has not been a single instance of a steel coil falling due to circuit board failure.Moreover,its surge protection is very practical.Even when the workshop voltage fluctuates occasionally,the board won’t restart,allowing the robot to continue its handling tasks and preventing steel coils from clogging the production line.Selection Guide/Purchase Recommendations When choosing the ABB DSQC612(3HAC15639-1),first confirm that your robot controller is from the ABB IRC5 series–it’s compatible with Compact,Single,and Multimove models.If it’s a controller from other brands(such as FANUC or KUKA),don’t choose it,as the interfaces and protocols are incompatible and it won’t work.Then consider the robot’s application scenario:if it’s for high-precision work(such as electronic assembly or precision welding),it’s absolutely suitable;if it’s just simple handling(error requirement≤5mm),although it can be used,if the budget is limited,you can consider the basic board.However,in terms of long-term stability,the ABB DSQC612(3HAC15639-1)is more reliable.Next,consider the controller…

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: