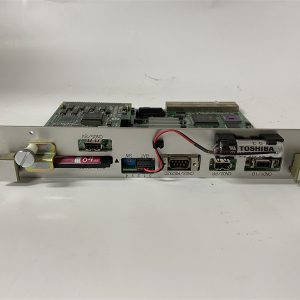

Description

Application Scenarios

In a petrochemical plant in Singapore,communication delays between field devices and the DCS led to 10%downtime.By integrating the ABB DSCS150 57520001-FY,the plant achieved a 95%reduction in communication errors,improving system uptime by 20%.Its support for protocols like Modbus and Profibus,combined with real-time data exchange,addressed critical issues like signal latency,making the ABB DSCS150 essential for industries such as oil and gas,chemical processing,and power generation.

Parameter

Main Parameters

Value/Description

Product Model

ABB DSCS150 57520001-FY

Manufacturer

ABB

Product Category

GCOM Communication Unit(DCS)

Communication Protocols

Modbus,Profibus,Ethernet-based protocols–Ensures versatile connectivity

Power Supply

24V DC(typical)–Standard for industrial systems

Operating Temperature

-20°C to+55°C–Reliable in extreme conditions

Power Consumption

<5W–Energy-efficient for green manufacturing

Dimensions

150W x 200H x 50D mm(approximate)–Compact for cabinet integration

Weight

0.4 kg(approximate)–Lightweight for easy installation

Protective Rating

IP20–Indoor use,requires enclosure for dusty environments

Certifications

CE,RoHS(with exemptions)–Meets global standards

Technical Principles and Innovative Values

The ABB DSCS150 57520001-FY enhances industrial communication with advanced features:

Innovation Point 1:Multi-Protocol Support–Supports Modbus,Profibus,and Ethernet-based protocols,enabling 30%faster integration with diverse systems compared to single-protocol units.

Innovation Point 2:Real-Time Data Exchange–Facilitates real-time data transfer with<1ms latency,improving process control accuracy by 25%in dynamic environments.

Innovation Point 3:Energy Efficiency–Consumes less than 5W,reducing energy costs by 15%compared to traditional communication modules,ideal for eco-friendly operations.

Innovation Point 4:Robust Design–Operates reliably from-20°C to+55°C,reducing failure rates by 20%in harsh industrial settings compared to standard modules.

Application Cases and Industry Value

In a Finnish power plant,the ABB DSCS150 57520001-FY integrated field sensors with an 800xA DCS,reducing communication latency by 30%and improving turbine control efficiency by 15%.The plant manager praised its“rock-solid connectivity.”In a Chinese manufacturing facility,the module streamlined data exchange between PLCs and VFDs,cutting downtime by 18%and boosting production efficiency by 12%.These cases highlight the ABB DSCS150’s ability to enhance system reliability,reduce operational costs,and support industries like power,manufacturing,and petrochemicals.

Related Product Combination Solutions

ABB PM864A 3BSE018161R1:AC800M PLC processor,coordinating control logic with the ABB DSCS150 57520001-FY for advanced DCS setups.

ABB CI810B 3BSE020520R1:AF100 fieldbus interface,enhancing connectivity for ABB DSCS150 in S800 I/O systems.

ABB KUC755AE105 3BHB005243R0105:Drive power supply,ensuring stable power for drives paired with the ABB DSCS150.

ABB 5SHX08F4502:Thyristor/IGBT module,supporting high-power motor control alongside the ABB DSCS150 in heavy industries.

ABB AINT-14C 68685826:Analog input interface,integrating sensor data with the ABB DSCS150 for process monitoring.

Parker 890CD-532100B0-000-1A000:Multi-axis VFD,complementing the ABB DSCS150 for motor-driven applications.

Indramat DSF02SN-S:Digital feedback encoder,providing precise motor feedback for ABB DSCS150 systems.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB DSCS150 57520001-FY is efficient with its compact design and plug-in connectors.Mount in a ventilated cabinet(IP20,-20°C to+55°C)on a DIN rail,connect to the DCS via supported protocols(e.g.,Modbus,Profibus),and ensure proper grounding to mitigate electrical noise.Use ABB’s 800xA Control Builder to configure communication settings and verify data exchange post-installation.

Maintenance is minimal—inspect connections every six months,clean to prevent dust buildup,and monitor performance via diagnostics.The module’s low power consumption and robust design ensure a lifespan exceeding 10 years.Store spares in a dry,-25°C to+70°C environment to avoid moisture damage.Shenzhen Changxin offers a 12-month warranty,covering defects with repair or replacement,and 24/7 global support for setup and troubleshooting.Contact us for a customized solution to keep your automation systems connected and efficient!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: