Description

Product Overview

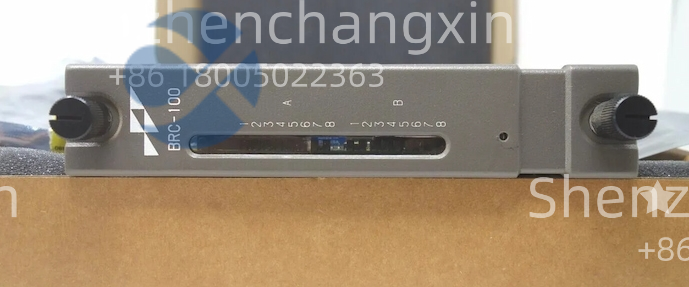

TheABB BRC100 PHCBRC10000000is a specialized communication interface module designed for ABB’s industrial automation systems,particularly for remote I/O applications.This module serves as a critical communication gateway that enables the connection between a central controller(such as a PLC or DCS)and remote I/O stations distributed throughout a plant or facility.TheABB BRC100module implements a high-speed,deterministic fieldbus protocol—typically PROFIBUS DP or another industrial network protocol—allowing it to efficiently manage the exchange of I/O data between the central control system and field devices located far from the main control cabinet.

As a key component in distributed control architectures,theABB BRC100 PHCBRC10000000module is typically installed in a remote I/O station where it acts as the master interface for that station.It scans the local I/O modules(digital and analog inputs/outputs)connected to it and packages this data for transmission to the central controller over the fieldbus network.Simultaneously,it receives output data from the controller and distributes it to the appropriate local output modules.This distributed approach significantly reduces wiring costs and complexity by allowing field devices to be connected locally while maintaining centralized control logic.The module’s robust design ensures reliable communication even in electrically noisy industrial environments.

The value of theABB BRC100 PHCBRC10000000lies in its ability to enable scalable,flexible,and cost-effective automation system architectures.By facilitating the implementation of remote I/O stations,it allows engineers to place I/O points closer to field devices,minimizing long cable runs and associated installation costs.The module’s support for high-speed communication ensures timely data exchange critical for real-time control applications.For maintenance teams,theBRC100provides diagnostic capabilities that help quickly identify communication issues or module failures,reducing troubleshooting time and improving system availability.

Technical Specifications

Parameter Name

Parameter Value

Manufacturer Part Number

BRC100

Full Part Number

PHCBRC10000000

Manufacturer

ABB

Product Type

Remote I/O Communication Interface Module

Communication Protocol

PROFIBUS DP(typically)

Transmission Speed

Up to 12 Mbps(auto-negotiating)

Station Address

Configurable via DIP switches or software

I/O Capacity

Dependent on connected I/O modules

Power Supply

24 VDC(typically from baseplate)

Power Consumption

Typically 5-10W

Operating Temperature

0°C to+60°C

Storage Temperature

-40°C to+85°C

Relative Humidity

5%to 95%non-condensing

Protection Rating

IP20(for installation in control cabinet)

Communication Ports

PROFIBUS DP(RS485)with terminal blocks

LED Indicators

Power,Communication Status,Error

Main Features and Advantages

TheABB BRC100 PHCBRC10000000offers several advanced features that make it ideal for distributed control applications.Its implementation of the PROFIBUS DP protocol provides deterministic,real-time communication with the central controller,ensuring that I/O data is exchanged within defined cycle times.The module supports a substantial number of I/O points through the expansion of additional I/O modules on the local bus,providing scalability to meet application requirements.

A significant advantage of theBRC100is its comprehensive diagnostic capability.The module continuously monitors the communication link to the controller and the status of the local I/O system.It can detect and report various fault conditions such as communication interruptions,module failures,and configuration errors.These diagnostics are accessible both locally via LED indicators and remotely through the control system,enabling rapid fault identification and resolution.The module’s rugged industrial design ensures reliable operation in challenging environments with electrical noise,vibration,and temperature variations.

TheABB BRC100 PHCBRC10000000is designed for easy integration and maintenance.Its configuration is straightforward,typically involving setting the station address via DIP switches and configuring the I/O mapping in the engineering software.The module supports features such as module replacement without addressing(if supported by the master),which simplifies maintenance procedures.The combination of robust communication performance,comprehensive diagnostics,and ease of use makes theBRC100a reliable solution for extending control system reach while maintaining performance and reliability.

Application Field

TheABB BRC100 PHCBRC10000000communication module is deployed in various industrial sectors where distributed I/O architecture is beneficial.In manufacturing plants,it is used to create remote I/O stations near machine clusters or production lines,reducing the wiring to a central control room.In process industries such as oil and gas,chemical,and water treatment,it enables I/O distribution across large facility areas for pump stations,valve manifolds,and tank farms.

The module is particularly valuable in applications with geographically dispersed equipment,such as conveyor systems in material handling,where placing I/O stations along the conveyor path significantly reduces wiring.In building automation,it can be used to create distributed control nodes for HVAC,lighting,and access control systems.Essentially,any application requiring cost-effective extension of control system I/O beyond the main control cabinet is a suitable application for theABB BRC100.

Related Products

ABB I/O Modules(DI,DO,AI,AO):Various signal modules that connect to theBRC100to form a complete remote I/O station.

ABB Power Supply Module:Provides power to the remote I/O station including theBRC100.

ABB Baseplate/Backplane:The mounting and interconnection system for theBRC100and I/O modules.

ABB Central Controller(PLC/DCS):The master controller that communicates with theBRC100over the fieldbus.

ABB Engineering Software:Used to configure theBRC100and the entire I/O system.

Installation and Maintenance

Installation preparation:Before installing theABB BRC100 PHCBRC10000000,ensure the remote I/O station is powered down.Verify the module’s compatibility with the existing system and I/O modules.Set the PROFIBUS DP station address correctly using the DIP switches according to the system configuration.Plan the cable routing for the PROFIBUS DP network,ensuring proper termination and segregation from power cables.

Maintenance recommendations:Regularly check the LED indicators on theBRC100for normal operation(power OK,communication active).Keep the module and surrounding area clean and dust-free.If communication faults occur,verify the station address,cable connections,and terminations.Use the diagnostic information available in the control system to identify issues.Have a spareBRC100module available for critical applications to minimize downtime in case of failure.

Product Guarantee

We understand that communication modules like theABB BRC100 PHCBRC10000000are critical for the operation of distributed control systems.We are committed to providing genuine,fully tested modules that guarantee compatibility and reliable performance.OurBRC100modules are sourced to meet original ABB specifications,ensuring seamless integration with your existing automation infrastructure.We provide technical support to assist with configuration and troubleshooting,helping you maintain the efficiency and availability of your control systems.Our goal is to be your trusted partner for automation component needs.

选择深圳长欣,享受无忧的售后服务和高品质产品。我们只与行业一线品牌厂商合作。

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: