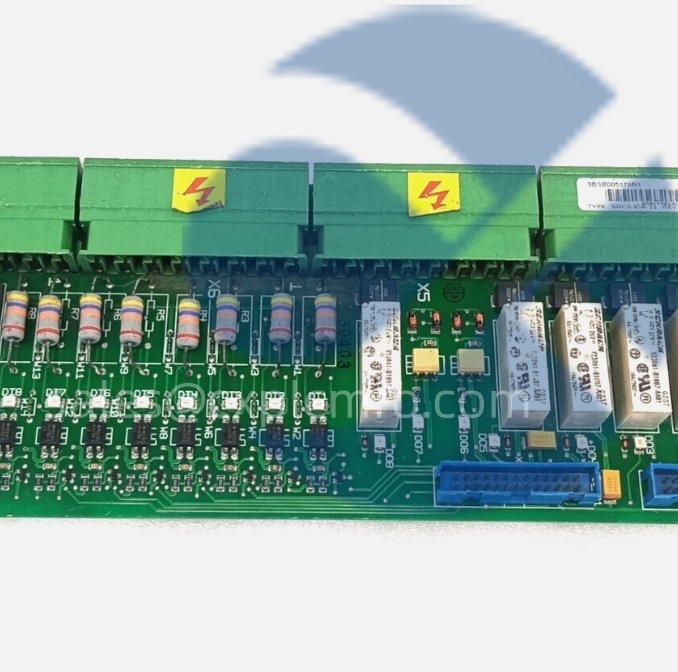

Description

Application Scenarios:

In a modern pharmaceutical plant, a Siemens S7-400 PLC controls a complex batch process, but the engineering team needs to integrate high-density, high-accuracy analog input modules from ABB’s S800 line for critical temperature and pressure monitoring. The solution is the ABB DSPC174 3BSE005461R1. Installed as the head module in a remote S800 I/O station, it connects the ABB analog modules directly to the plant’s existing Profibus DP backbone. The Siemens PLC now reads all sensor data as if it were native, solving the key pain point of multi-vendor interoperability without costly system redesign. The DSPC174 translates complex process data into a standard Profibus telegram, ensuring the high-fidelity measurement of the ABB I/O is fully utilized by the main controller for precise loop control and regulatory compliance, demonstrating its critical role as a universal communication bridge.

Technical Principles and Innovative Values:

Innovation Point 1: Universal Profibus DP-V1 Slave Functionality. The core innovation of the ABB DSPC174 is its ability to make the entire ABB S800 I/O system appear as a standard Profibus slave device on the network. It handles all complex protocol communication, including cyclic data exchange for process I/O and acyclic services for parameterization and advanced diagnostics (DP-V1), freeing the host controller from low-level communication tasks.

Innovation Point 2: Intelligent Configuration and Data Mapping. The module features a dedicated microprocessor that manages the data exchange between the Profibus network and the connected S800 I/O modules. It allows for flexible configuration of the I/O data layout within the Profibus telegram, enabling optimal use of the available bandwidth and seamless integration with the data structures expected by the master PLC.

Innovation Point 3: Hot Insertion and Removal Support. Designed for high-availability systems, the DSPC174 3BSE005461R1. along with its S800 I/O modules, supports hot-swapping. This allows for the replacement or addition of I/O modules or the communication interface itself without shutting down the entire Profibus segment or the control system, significantly reducing maintenance downtime.

Application Cases and Industry Value:

A large water treatment plant was undergoing a control system expansion. The existing infrastructure was built around a Profibus DP network with several third-party PLCs. For the new clarification and filtration bays, the engineers selected ABB S800 I/O for its superior analog measurement stability and compact density. The challenge was integrating this new ABB I/O without altering the existing network architecture or PLC programming. By deploying ABB DSPC174 modules in each new S800 station, the ABB I/O was seamlessly added as additional Profibus slaves. The project was completed 30% faster because the PLC programmers used standard Profibus diagnostic and configuration tools they already knew. The plant manager reported enhanced system visibility and reduced commissioning complexity, crediting the DSPC174 for enabling a best-of-breed solution that leveraged existing assets while incorporating superior technology.

Related Product Combination Solutions:

TU810/TU830/TU833: S800 baseplates (terminal units) that provide the mechanical and electrical backbone for mounting the DSPC174 and other S800 I/O modules.

SD821/SD822: S800 Digital Input and Output modules that would be controlled through the ABB DSPC174 Profibus interface.

SA821/SA822: S800 Analog Input and Output modules, ideal for process value integration via the DSPC174.

S800 I/O Power Supply (e.g., for TU810): Provides the necessary power to the baseplate and all connected modules, including the DSPC174.

Profibus Connector (9-pin D-sub) & Cable: Standard Profibus network components used to physically connect the ABB DSPC174 3BSE005461R1 to the bus.

CI854: An ABB AC 800M controller communication interface that can act as a Profibus DP master, communicating with the DSPC174 slave.

Control Builder Professional: ABB’s engineering tool used to configure the S800 I/O station layout, parameters, and the data mapping for the DSPC174 module.

Installation, Maintenance, and Full-Cycle Support:

Installation of the ABB DSPC174 3BSE005461R1 is straightforward within the S800 framework. First, the appropriate S800 baseplate (TU) is mounted and wired. The DSPC174 is then inserted into the left-most slot (position X1) of the baseplate, where it automatically receives power and establishes communication with the backplane. The Profibus network cable is connected to its 9-pin port. Configuration is performed using engineering software like Control Builder, where the module’s Profibus address and the data map for the attached I/O modules are defined. The module’s LEDs provide immediate status: a steady green OK light indicates proper operation, while flashing patterns signal configuration or communication faults.

Routine maintenance is minimal. The primary tasks involve ensuring the Profibus connector is secure and monitoring the status LEDs. The most common issues are communication faults, usually resolved by verifying the Profibus address and baud rate settings, and checking network termination and cable integrity. The hot-swap capability allows for safe replacement. We provide guaranteed genuine ABB DSPC174 modules, ensuring full compatibility and performance. Our technical support can assist with configuration file setup, troubleshooting network integration issues, and guidance on optimizing data exchange for your specific application, ensuring a reliable and efficient communication link for your distributed I/O system.

Contact us for genuine ABB communication interfaces and expert support for your system integration projects.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: