Description

Application Scenarios

In a petrochemical refinery’s tank farm, level and temperature transmitters installed in Zone 1 hazardous areas (where flammable vapors may be present) generate critical 4-20mA signals. Running these signals directly into the main Distributed Control System (DCS) cabinet in the safe area presents a significant risk: fault energy from the safe-area wiring could potentially travel back into the hazardous area, creating an ignition source. The ABB TB852 3BSC950263R1 is the engineered safety barrier that mitigates this risk. Installed in an interface cabinet at the boundary between the hazardous and safe areas, it accepts the 4-20mA input from the field transmitter. Its internal galvanic isolation and energy-limiting circuits ensure that under any fault condition—be it a short circuit or a voltage surge from the safe area—the energy passed into the hazardous area is strictly limited to a intrinsically safe level, below what is needed to cause ignition. It then provides a clean, isolated, and identical 4-20mA output to the S800 I/O card (PFEA111-20). This allows the DCS to safely monitor and control the process while rigorously maintaining the required safety integrity, directly addressing the critical pain points of personnel safety, asset protection, and regulatory compliance.

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Certified Galvanic Isolation for Hazardous Area Safety. The core innovation of the ABB TB852 3BSC950263R1 is its provision of certified galvanic isolation. It incorporates transformer or opto-isolator-based circuitry that physically and electrically separates the input (hazardous area) circuit from the output (safe area) circuit and the power supply. This triple isolation ensures that no single fault—such as a short circuit or a high voltage from the safe-area side—can transmit dangerous levels of energy into the hazardous area. This design is essential for achieving and maintaining certifications like ATEX and IECEx for intrinsic safety (Ex ia or Ex ib) interfaces, forming a reliable and compliant safety barrier.

Innovation Point 2: Integration with the S800 I/O Architecture. Unlike generic standalone isolators, the TB852 is designed as a native component of the ABB S800 I/O ecosystem. It is typically installed in a dedicated interface cabinet or marshalling rack and connects seamlessly to standard S800 I/O cards like the PFEA111-20 analog input module. This integration simplifies system design, reduces wiring complexity, and ensures compatibility. Engineers can configure and monitor the entire signal chain—from field device to controller—within the same engineering tool (Control Builder), streamlining both commissioning and diagnostics.

Innovation Point 3: Signal Integrity and Diagnostic Capabilities. Beyond mere isolation, the TB852 conditions the signal. It provides high noise immunity, protecting the sensitive control system from ground loops, electromagnetic interference (EMI), and voltage transients commonly found in industrial environments. Many variants also feature basic diagnostics, such as the ability to detect an open-circuit condition on the field side. This proactive fault detection allows maintenance teams to be alerted to a broken transmitter wire before the process is affected, supporting predictive maintenance strategies and reducing unscheduled downtime.

Application Cases and Industry Value

Case Study: Offshore Natural Gas Processing Platform. An offshore platform required an upgrade to its gas compression control system. Dozens of pressure and vibration transmitters on the gas compressors were located in Zone 1 hazardous areas. The project had a strict mandate: all interfaces must meet the latest ATEX and SIL requirements. The system integrator chose the ABB TB852 3BSC950263R1 modules to serve as the intrinsic safety barriers. They were installed in Ex-certified junction boxes close to the process area. The signals were then passed to S800 I/O racks in the non-hazardous control room. The lead engineer reported: “Using the TB852 modules gave us a pre-certified, neat solution that simplified the safety calculations. Their integration with the S800 system cut our commissioning time significantly. Most importantly, they provided the robust, fault-tolerant isolation we needed to meet the platform’s stringent safety case.”

Case Study: Pharmaceutical API Synthesis Plant. A facility producing active pharmaceutical ingredients (APIs) used solvent-intensive batch processes classified under Zone 1. Their existing 4-20mA loops used zener diode barriers, which required a dedicated, clean ground connection that was difficult to maintain and prone to issues. Seeking a more reliable and maintainable solution, they migrated to a system using ABB TB852 3BSC950263R1 galvanic isolators. The isolated design eliminated the need for the special ground, solving persistent signal noise problems. The modular, DIN-rail mounting allowed for a much cleaner and more organized marshalling cabinet. The plant’s instrumentation supervisor noted: “Switching to the TB852 isolators resolved our chronic ground loop issues overnight. The signal quality to our ABB control system improved dramatically, leading to better process control consistency. Maintenance is also simpler—if a channel fails, we just replace one module without affecting the grounding system.”

Related Product Combination Solutions

ABB PFEA111-20: The 8-channel analog input module that receives the isolated 4-20mA signal from the TB852 and converts it to a digital value for the controller.

ABB PFEA111-65: The analog output module. In a control loop, a command from the controller via a PFEA111-65 might be sent through a TB852 (or similar output isolator) to a valve positioned in a hazardous area.

ABB EI813 / EI823F: The S800 Electronic Interface base units that provide communication and power for the I/O system, to which the signals processed by the TB852 are ultimately sent.

ABB SD821 / SD822: Digital input/output modules. For discrete signals from hazardous areas, similar isolation concepts are applied using associated digital isolators or relays, often used alongside the TB852 in the same marshalling cabinet.

ABB CI854: A Profibus DP communication interface for the S800 station. The data from field devices, after conditioning by the TB852. is communicated to the higher-level controller via such modules.

ABB TU847 / TU837: Terminal units for analog and digital signals. The TB852 modules are typically wired between the field terminations (on one side) and these S800 terminal units (on the other side).

ABB CPS-1 (e.g., 1SAP250100R0001): A compact power supply module that can provide the clean 24V DC power required for the TB852 and associated I/O modules.

Installation, Maintenance, and Full-Cycle Support

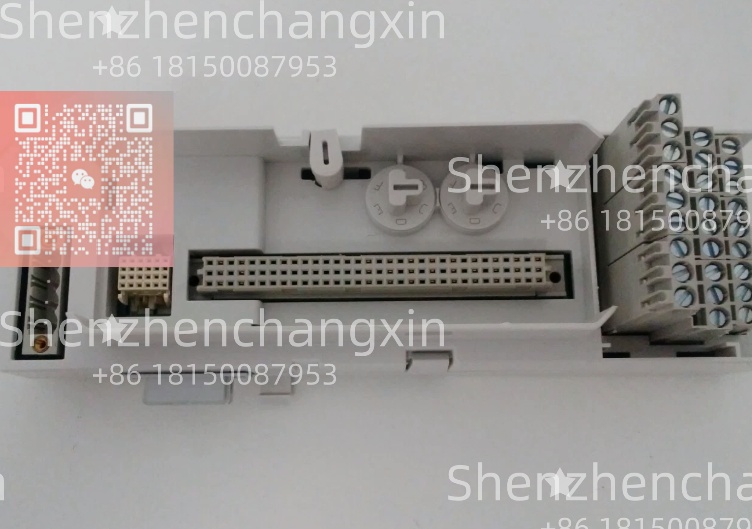

Installation of the ABB TB852 3BSC950263R1 requires careful planning according to hazardous area classification standards. The modules are typically mounted on DIN rails within a certified enclosure or a segregated marshalling cabinet at the boundary between hazardous and non-hazardous areas. Field wiring from the hazardous area devices must be done using approved methods (e.g., properly glanded cables) and connected to the input terminals. The output side is wired to the safe-area S800 I/O system. It is crucial to follow the specific certification documents (Ex certificates) and wiring diagrams to ensure the safety integrity of the loop is maintained. Correct labeling of all terminals and channels is essential for future maintenance and troubleshooting.

Maintenance is generally minimal due to the solid-state design of the module. Routine tasks involve visual inspection for any physical damage, checking terminal tightness, and verifying the integrity of the isolation barriers during periodic safety system checks. Most diagnostic information comes from the control system monitoring the signal itself; a sudden signal loss or fixed value may indicate a fault in the field device, wiring, or the TB852 module. Replacement is straightforward: once the field circuit is verified as de-energized or safe, the faulty module can be disconnected and a new one installed. Its plug-and-play design with the terminal blocks ensures quick restoration. Keeping a calibrated spare module on-site is a common practice to minimize downtime.

We provide comprehensive lifecycle support for the ABB TB852 3BSC950263R1. This includes supplying certified modules, assisting with hazardous area classification and system design, and providing the necessary certification documentation. Our technical team can help you select the correct variant for your safety requirements and ensure it is integrated properly with your S800 I/O and control system. We understand the critical role of safety interfaces and are committed to providing products and expertise that help you achieve a safe, reliable, and compliant automation system.

Ensure safety and signal integrity at the hazardous area boundary. Contact us for the ABB TB852 3BSC950263R1 and expert application support.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: