Description

3BHE031482R0101 Technical Specifications

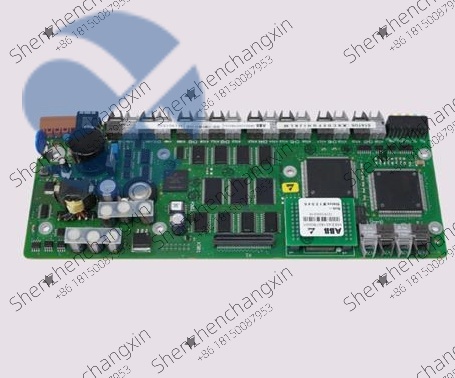

Product Model:3BHE031482R0101

Manufacturer:ABB

Product Type:I/O Module Base Unit/Backplane

Alternative Name/Replacement:S800-SB8(functionally equivalent)

System:ABB Symphony®Plus/800xA

Function:Mounting and communication backplane for S800 series I/O modules

Number of Slots:8 independent slots

Compatible Modules:All ABB S800 series I/O modules(such as DI,DO,AI,AO,communication modules,etc.)

Mounting Method:Standard 35 mm DIN Rail Mounting

Bus Type:S800 Dedicated High-SpeedBackplane Bus

Addressing:Supports mechanical addressing(module position is automatically identified by side coding strips)

Hot-Swap Support:Supports hot swapping of I/O modules,with automatic system recognition

Communication Interface:Connects to S800 communication modules(such as AIB,AIE,GFD,etc.)via the bus

Power Supply:Power is drawn from the I/O station power module via the backplane(typically+24 VDC and+5 VDC)

Operating Temperature:0°C to 55°C

Storage Temperature:-40°C to 85°C

Protection Rating:IP20(for use in control cabinets)

Dimensions(W×H×D):Approximately 240×115×70 mm

Weight:Approximately 0.8 kg

LED Indicator:Some versions have slot status indicators(depending on the module installed).

3BHE031482R0101 Product Overview

Hey guys,today we’re talking about this ABB The 3BHE031482R0101 isn’t just some”accessory”;it’s the”foundation”and”highway”of the ABB S800 I/O system!Don’t underestimate it:it’s just a plastic and circuit board base.Without it,even the most advanced I/O modules are useless.

This unit,technically known as the I/O Base Unit(S800-SB8),is the standard carrier for mounting eight S800 series I/O modules in ABB’s 800xA and Symphony Plus DCS systems.Imagine a remote I/O station needs to connect hundreds of temperature,pressure,and switch signals.You can’t run individual cables for each module,right?You need a”skeleton”to connect them all—that’s the purpose of the 3BHE031482R0101.

It’s not just physical support;it also acts as an electrical bus channel.After all I/O modules are plugged in,data is transmitted to a communication module(such as an AIB or GFD)via the high-speed backplane bus on the backplane,and then back to the main control room via optical fiber or Profibus.It also supports mechanical address coding—a small coding strip on the side of each backplane automatically identifies the station and slot number upon insertion,eliminating the need for manual IP or address configuration,saving time and effort.

Most impressively,the hot-swappable function allows you to remove and replace a faulty module without shutting down the system.The system automatically recognizes the module and preserves data.This is a life-saving feature in power plants and chemical plants,where downtime is essential.

Main Features and Advantages

Let’s start with system integration.The ABB 3BHE031482R0101 is tailor-made for the S800 I/O series.It’s a natural pairing with ABB’s DI,DO,AI,AO,and communication modules.Plug it in and it’s recognized instantly,requiring no drivers or configuration.Are you using a third-party backplane?Compatibility,signal integrity,and EMC issues are all potential pitfalls.

Let’s talk about reliability.The industrial-grade design and circuit boards feature conformal coating(moisture-proof,dust-proof,and chemical-resistant),ensuring stable operation in high-temperature,high-humidity,and strong electromagnetic interference environments.DIN rail mounting ensures firm,stable operation,and vibration resistance.The backplane bus features precise impedance matching,ensuring distortion-free signal transmission and an extremely low bit error rate.

Hot-swappability and address encoding are two key features.During on-site maintenance,electricians can replace modules without powering down,significantly reducing downtime.Mechanical coding strips automatically identify station and slot numbers,eliminating human configuration errors.This makes it particularly suitable for large-scale projects with hundreds of I/O stations.

It also offers strong scalability.An I/O station can cascade multiple 3BHE031482R0101 backplanes,connected in series via bus connectors,to expand to dozens of modules,meeting I/O needs of all sizes.

Finally,maintenance is easy.The backplane itself is passive and virtually maintenance-free.LED status indicators are displayed based on the installed module,making it easy to identify any slot errors at a glance.To replace it,simply unscrew two screws,pull out the old baseplate,replace it with the new one,and rewire it.An experienced engineer can do it in ten minutes.

The ABB 3BHE031482R0101 is a fundamental component in the ABB S800 I/O system,serving as the mechanical and electrical backbone for modular I/O configurations in Symphony®Plus and 800xA control systems.This 8-slot base unit provides a robust platform for hot-swappable I/O modules,enabling flexible and scalable system expansion in demanding industrial environments.Featuring automatic address coding via mechanical keying and a high-integrity backplane bus,it ensures reliable data transmission and simplifies commissioning and maintenance.Designed for DIN-rail mounting and seamless integration with ABB’s ecosystem,the ABB 3BHE031482R0101 delivers exceptional durability and operational continuity,making it an essential element in power generation,oil&gas,and process automation applications worldwide.

Application areas

This ABB 3BHE031482R0101,the main battlefield is the remote I/O station and distributed control cabinet.You can see them installed in rows in the boiler rooms and turbine rooms of thermal power plants,receiving temperature,pressure,and valve feedback signals.In on-site cabinet rooms at petrochemical plants,they transmit hundreds or even thousands of DI/DO points back to the central control room.In pump stations at water treatment plants,they create small I/O stations,enabling unmanned operation.

In addition,in industries like metallurgy,cement,and papermaking,the ABB 3BHE031482R0101 is standard equipment for any ABB 800xA system.It’s particularly useful in retrofitting older plants,replacing the traditional terminal block+PLC solution with this module,offering simplified wiring,easy maintenance,and strong anti-interference capabilities.

Selection Guide/Purchasing Recommendations

Before installing the ABB 3BHE031482R0101,please confirm three points:

First,is your system an S800 series system?Do not plug in I/O modules from other brands;they will not match.

Second,check the integrity of the address coding strips on the backplane.Missing or broken ones can cause the system to fail to recognize them.

Third,avoid buying second-hand,disassembled backplanes!These plastic parts age and crack easily,becoming loose after a few plugs and unplugs,leading to poor contact and serious problems.

Our advice:Buy brand-new,genuine parts.Ensure the coding strips are intact,the gold fingers are free of oxidation,and the structure is undamaged.This provides peace of mind.

Customer Case Study/Successful Application Analysis

Last year,a chemical plant in Jiangsu province ran out of I/O station backplanes for an expansion project.They purchased a batch of refurbished 3BHE031482R0101s.However,after three months of operation,communication in multiple slots became intermittent.After further investigation,they discovered oxidation in the gold fingers on the backplanes.They contacted us,and we shipped a batch of brand-new,genuine backplanes.After replacing them,communication became stable,and the system has had no further issues.Customers say,”Although the baseboard is small,it’s the lifeblood of the system.Next time,I’ll only trust genuine new parts!”

Related Products

ABB 3BHE031481R0101:S800 4-slot baseboard(S800-SB4),for small I/O stations.

ABB 3BHE031483R0101:S800 16-slot baseboard(S800-SB16),for large expansion.

ABB S801:S800 I/O station processor module,for controlling independent I/O stations.

ABB AIB100/AIB104:S800 communication interface modules,connecting to Profibus or Modbus networks.

ABB DI810/DO810:8-channel digital input/output modules,typically installed on the 3BHE031482R0101.ABB AI810/AO810:Analog input/output modules for temperature,pressure,and control valves.

ABB GFD233A:Fiber optic communication module for remote I/O station networking.

ABB S800 PS:S800 power supply module,provides+24VDC and+5VDC to the baseplate and I/O modules.

Pre-Installation Preparation

Before installing the ABB 3BHE031482R0101,turn off the power first!Do not operate with power on.Install the DIN rail flat and secure the clips on both sides of the baseplate.Check that the address code strips match the design drawings.Avoid touching the gold-finger prints;wipe any grease with anhydrous alcohol.Before inserting an I/O module,confirm the model and orientation to avoid inserting it the wrong way around.After powering on,check that the communication module recognizes all slots and whether there are any alarms.

Maintenance Recommendations

This ABB 3BHE031482R0101 is essentially maintenance-free,but it’s recommended to inspect the following every six months:

Check the baseplate for looseness and broken clips.

Check the gold fingers for oxidation and dust accumulation;clean with an eraser if necessary.

Check that the inserted modules are secure and show no signs of overheating.

Check that the address code strips are intact and not lost.

Remember,the baseplate is the foundation;without a stable foundation,even the most luxurious superstructure is useless.

Product Guarantee

At Shenzhen Changxin,we take every ABB 3BHE031482R0101 seriously.Upon arrival,we first inspect the exterior to check for cracks in the plastic and wear on the gold fingers.We then install a test module to verify bus communication,address recognition,and hot-swap functionality.We offer a three-year warranty and will replace all non-intentional damage.We don’t do one-time deals;we’re your lifelong supporter of industrial control spare parts.Trust us,we’ll stand behind you!

The ABB 3BHE031482R0101 is a critical enabler of modular I/O architecture in industrial automation,and at Shenzhen Changxin,we ensure every unit meets ABB’s original specifications for performance and reliability.Each base unit undergoes visual inspection,mechanical integrity testing,and functional validation with I/O modules to guarantee seamless integration.We offer a 3-year warranty,global logistics,and expert technical support.Our mission is to provide not just hardware,but confidence—knowing that your I/O infrastructure is built on a solid,trustworthy foundation.Partner with us,and you’re securing the backbone of your control system.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: