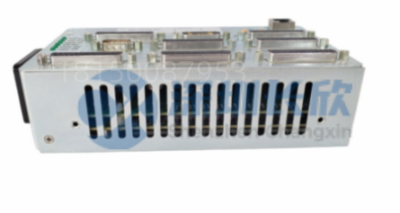

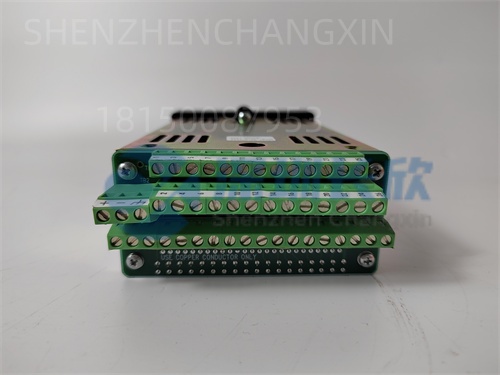

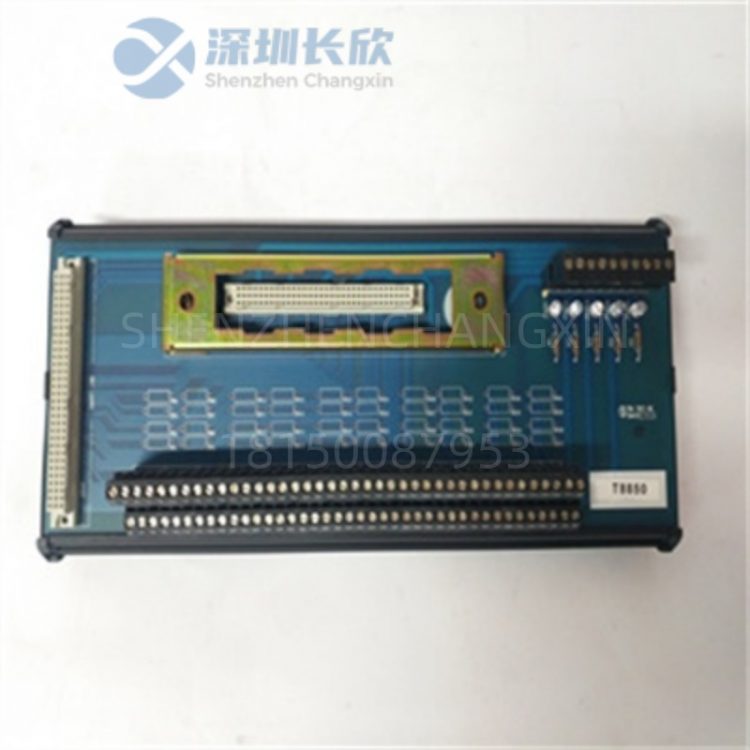

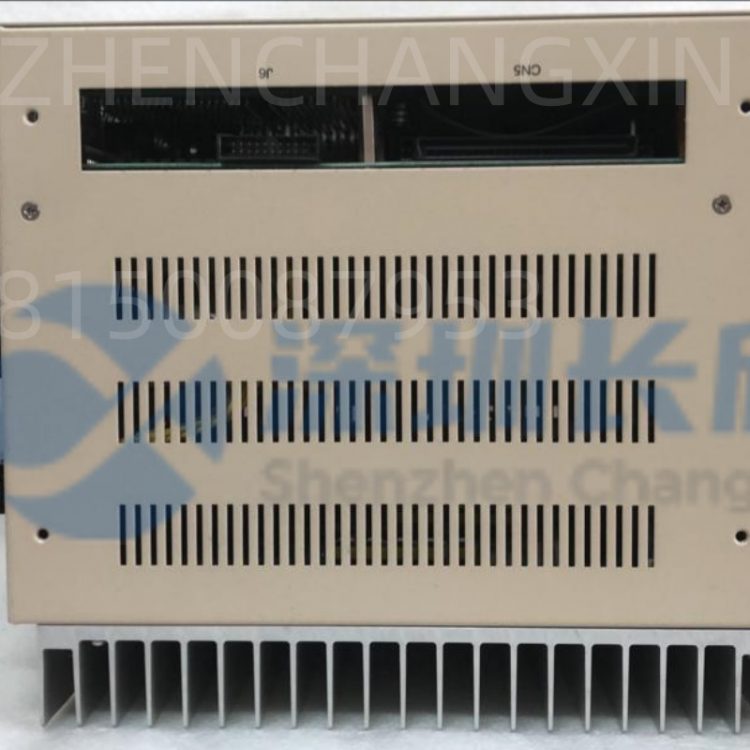

LAM 853-150806-001 – Precision Motion Control PCB for Semiconductor Wafer Processing Equipment

Description The LAM 853-150806-001 is a proprietary printed circuit board assembly (PCBA) designed by LAM Research for use in its advanced plasma etch systems, including the Kiyo® and Flex™ families. This module serves as a critical interface between the tool’s central motion controller and precision mechanical subsystems—such as wafer handling robots, electrostatic chucks (ESCs), and chamber lift…

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: