Description

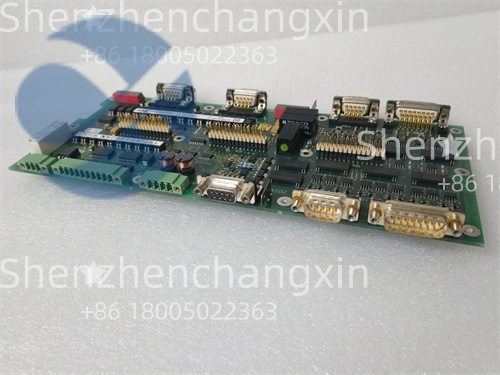

The ABB UFC762AE101 (3BHE006412R0101) is an 8-slot I/O baseplate designed for ABB’s AC 800M programmable automation controller platform, serving as the mechanical and electrical backbone for local I/O modules in distributed control systems. It provides a robust, DIN-rail-mounted carrier with an integrated backplane that delivers power and high-speed communication between I/O modules (e.g., DI810. AI810. DO810) and the central AC 800M CPU.

Engineered for reliability in demanding industrial settings, the UFC762AE101 supports modular expansion, simplified wiring, and rapid module replacement—making it ideal for process industries requiring flexibility and uptime.

Application Scenarios

At a Scandinavian pulp and paper mill undergoing a brownfield automation upgrade, engineers needed to replace obsolete relay panels with a modern, scalable I/O system without expanding cabinet space. By installing ABB UFC762AE101 3BHE006412R0101 baseplates alongside PM864A controllers, they consolidated 12 legacy racks into just 3 compact enclosures. Each UFC762AE101 hosted a mix of analog inputs for steam pressure, digital outputs for motor starters, and a CI854 Profibus module for remote drives. The result: 40% faster commissioning, 60% less wiring labor, and zero unplanned outages during the 18-month transition. “The baseplate didn’t just hold modules—it held the project together,” said the lead automation engineer.

Technical Principles and Innovative Values

Innovation Point 1: The UFC762AE101 features a gold-plated, high-reliability backplane connector system that ensures stable signal integrity—even in high-vibration environments like compressors or turbines—reducing intermittent communication faults common with low-cost carriers.

Innovation Point 2: Modular slot design allows any combination of digital, analog, or communication modules in a single baseplate, enabling application-specific I/O tailoring without custom hardware—ideal for skid builders and OEMs.

Innovation Point 3: Tool-free module retention clips allow quick insertion and removal of I/O cards during maintenance or upgrades, minimizing downtime in continuous processes like refining or power generation.

Innovation Point 4: Built-in keying prevents incorrect module insertion (e.g., forcing an output module into an input-only configuration), enhancing safety and reducing commissioning errors.

Application Cases and Industry Value

In a Middle Eastern desalination plant, UFC762AE101 baseplates were deployed to monitor high-pressure RO membranes and control brine discharge valves. Despite ambient temperatures exceeding 50°C and salt-laden air, the baseplates maintained flawless operation for over three years—thanks to conformal-coated PCB options and wide-temperature-rated components. Maintenance costs dropped by 35% due to simplified module swaps during routine calibration.

Similarly, a U.S. biopharma facility used UFC762AE101 units in cleanroom HVAC control panels. The compact footprint allowed integration into tight wall-mounted enclosures, while the standardized ABB architecture ensured seamless validation under FDA 21 CFR Part 11—accelerating audit readiness by weeks.

Related Product Combination Solutions

ABB PM864A / PM865: AC 800M CPUs that communicate with I/O on UFC762AE101 via ribbon cable or direct backplane.

ABB DI810 (3BSE008516R1): 16-channel digital input module—commonly installed in UFC762AE101 for switch/status monitoring.

ABB AI810 (3BSE008512R1): Analog input module—for 4–20 mA sensors (pressure, temperature, flow).

ABB DO810 (3BSE008518R1): Digital output module—to drive relays, solenoids, and alarms.

ABB CI854A (3BSE013250R1): Profibus DP master—fits in UFC762AE101 for remote I/O or drive networks.

ABB UFC718AE01: Alternative 8-slot baseplate with different form factor—verify compatibility before substitution.

ABB Automation Builder / Control Builder M: Engineering software for configuring I/O assignments on UFC762AE101-based systems.

Installation, Maintenance, and Full-Cycle Support

Install the ABB UFC762AE101 3BHE006412R0101 by securing it to a standard 35 mm DIN rail inside an IP54+ rated enclosure. Connect the backplane ribbon cable (or direct link) to the AC 800M CPU rack, ensuring proper orientation and strain relief. Insert I/O modules firmly until they click into place—no screws required. Verify power and communication LEDs after startup.

For maintenance, always de-energize the system before replacing modules unless operating in a certified hot-swap redundant configuration. Periodically inspect terminal blocks for torque and corrosion, especially in humid or corrosive environments. The baseplate itself requires no calibration or firmware updates—its passive design ensures decades of service life.

We supply every ABB UFC762AE101 3BHE006412R0101 as 100% new, factory-sealed stock from authorized ABB/HITACHI ENERGY channels—with original labeling, traceability documentation, and compliance certificates (CE, UL, etc.). Our technical team provides free compatibility verification, layout assistance, and rapid-response support for integration challenges. If any unit exhibits mechanical damage, backplane connectivity issues, or slot misalignment, we offer immediate replacement—because a reliable baseplate is the silent foundation of every successful control system.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: