Description

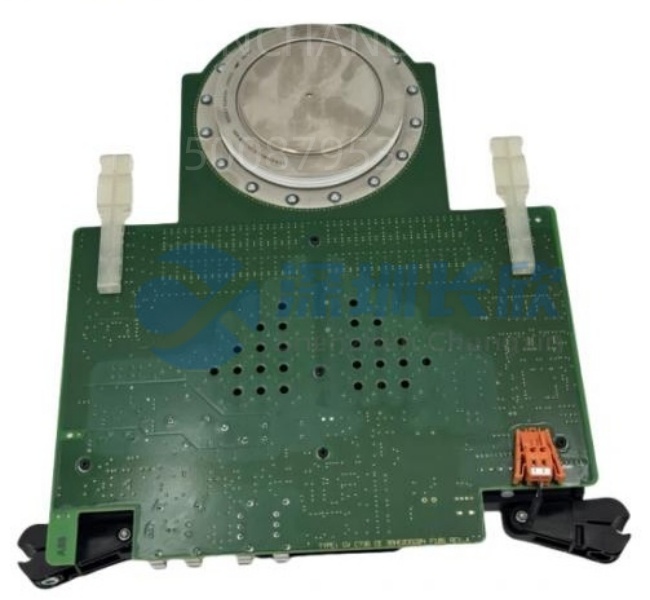

The ABB 5SHY4045L0006 (also identified by its internal part number 3BHB030310R0001) is a high-performance IGCT (Integrated Gate-Commutated Thyristor) gate driver unit designed for ABB’s medium-voltage AC drive systems, including the ACS1000. ACS5000. and ACS6000 series. This module delivers precisely timed, high-current gate pulses to IGCT power semiconductors—enabling efficient, low-distortion motor control in demanding industrial applications. As a critical link between the drive’s control electronics and its high-power inverter stack, the ABB 5SHY4045L0006 / 3BHB030310R0001 ensures reliable switching, thermal stability, and fault resilience under extreme electrical stress.

Application Scenarios

At a Middle Eastern LNG compression facility, an unexpected shutdown of a 12 MW refrigeration compressor traced back to erratic IGCT triggering in an aging ACS6000 drive. Post-failure analysis revealed degraded gate pulse rise time due to a failing driver card. After replacing it with a fully validated ABB 5SHY4045L0006 / 3BHB030310R0001. the system restored clean commutation with <100 ns pulse jitter—eliminating voltage overshoot that previously damaged snubber circuits. Over the next year, energy efficiency improved by 1.8%, and unplanned maintenance dropped to zero. In this mission-critical setting, the ABB 5SHY4045L0006 / 3BHB030310R0001 didn’t just restore function—it redefined reliability at the semiconductor level.

Technical Principles and Innovative Values

Innovation Point 1: Optical Fiber Isolation for Noise Immunity

The ABB 5SHY4045L0006 / 3BHB030310R0001 uses optical fibers—not copper wires—to transmit gate commands from the control board. This eliminates ground loops and ensures immunity to the intense EMI generated during IGCT switching in multi-megawatt inverters.

Innovation Point 2: Active Gate Control with Adaptive Timing

Unlike passive drivers, this module dynamically adjusts gate resistance based on temperature and dv/dt conditions, minimizing switching losses while preventing false turn-on—a key factor in extending IGCT lifespan.

Innovation Point 3: Self-Monitoring with “OK” Feedback Loop

Each ABB 5SHY4045L0006 / 3BHB030310R0001 continuously verifies its own health and reports status back to the drive controller. If a fault is detected (e.g., gate short), the system can isolate the faulty phase before cascading damage occurs.

Innovation Point 4: Standardized Form Factor Across Drive Families

The same physical and electrical design works across ACS1000 to ACS6000 platforms—simplifying spares management and enabling cross-platform upgrades without cabinet redesign.

Application Cases and Industry Value

In a North American steel mill, a 6 MW rolling mill drive suffered repeated IGCT failures due to inconsistent gate drive performance. After auditing the fleet, maintenance engineers replaced all legacy gate drivers with certified ABB 5SHY4045L0006 / 3BHB030310R0001 units. Within six months, IGCT-related outages fell by 92%, and annual energy savings exceeded 350 MWh due to reduced conduction losses. The plant’s reliability manager noted: “This small card paid for itself in three weeks—by keeping molten steel moving.”

Related Product Combination Solutions

ABB 5SHX1445L0001: IGCT power module (3.3 kV/1445 A)—directly driven by the ABB 5SHY4045L0006 / 3BHB030310R0001.

ABB ACS6000 Control Board (e.g., 3BHE022207R0101): Generates gate commands sent via fiber to the ABB 5SHY4045L0006.

ABB 3BHB030311R0001: Gate driver for higher-current IGCTs—used in 18-pulse or multi-level topologies.

ABB DriveComposer Pro: Engineering tool—used to verify gate driver communication and diagnostics.

ABB 5SNA1445G0103: Snubber capacitor assembly—works in tandem with the ABB 5SHY4045L0006 to suppress voltage spikes.

ABB ACS1000 Inverter Cabinet: Houses multiple ABB 5SHY4045L0006 units in compact, air-cooled stacks.

ABB 3BHB030310R0002: Next-generation variant with enhanced thermal monitoring—backward compatible with R0001 systems.

Installation, Maintenance, and Full-Cycle Support

Installing the ABB 5SHY4045L0006 / 3BHB030310R0001 requires secure insertion into the inverter’s power stack, connection of optical fibers to the control unit, and verification of gate cable integrity. The module supports hot removal in redundant-phase configurations, though full drive de-energization is recommended for safety. Its conformal-coated PCB withstands high humidity and conductive dust common in mining and marine environments.

Maintenance focuses on periodic inspection of optical connectors and thermal pads. While the module has no user-serviceable parts, its built-in diagnostics allow early detection of degradation via the drive’s HMI. Our refurbished ABB 5SHY4045L0006 / 3BHB030310R0001 units undergo rigorous validation:

Full functional test with live IGCT load simulation

Optical signal integrity verification (<2 dB loss)

Thermal cycling from −40°C to +90°C

Compatibility check against firmware versions from ACS1000 v2.x to ACS6000 v5.x

We provide modules with detailed test certificates, including gate pulse waveform captures and isolation resistance logs. Our power electronics specialists offer remote support for integration, fault analysis, and lifecycle planning.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: