Description:

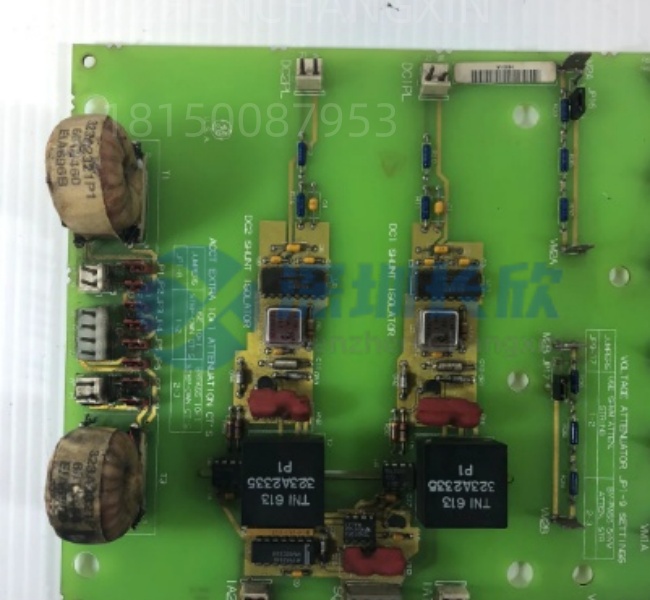

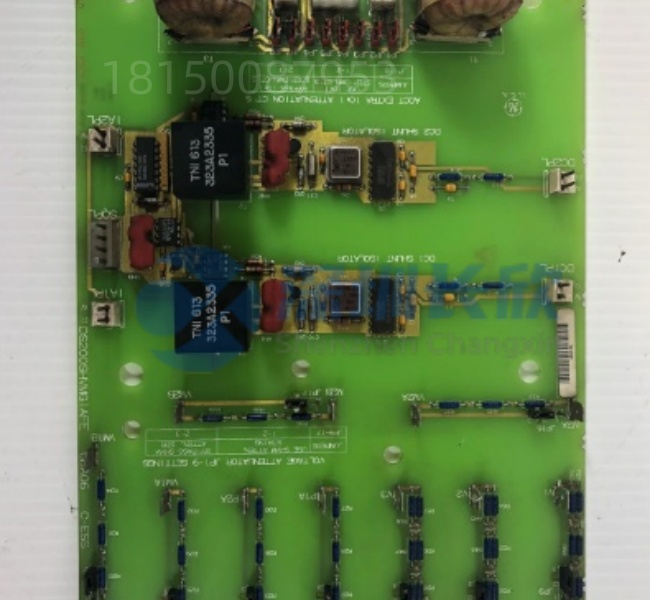

The General Electric DS200SHVMG1AFE is a Servo Drive I/O Termination Board designed for the Mark V gas/steam turbine control system. This critical board acts as the intelligent interface and signal conditioning hub within a servo drive assembly, managing the exchange of control signals, feedback, and power between the turbine’s main control and the servo valves that precisely regulate fuel and airflow.

Application Scenarios:

Within the servo drive cabinet of a GE Frame 7EA gas turbine, precise control of the fuel stroke reference (FSR) is paramount. The DS200SHVMG1AFE board is the central nervous system of this critical control loop. It receives a high-speed positioning command from the Mark V controller. This board conditions and relays that command to the final power amplifier stage while simultaneously monitoring critical feedback signals, such as the actual servo valve position from an LVDT. The board solves the core industrial challenge of ensuring signal integrity and reliability in a high-vibration, electrically noisy environment. Its failure can lead to a loss of precise valve control, causing immediate turbine load swings or even a protective trip. For a plant engineer, the DS200SHVMG1AFE represents the reliability of the entire fuel metering system; a glitch here directly threatens unit stability and availability.

Parameter:

Technical Principles and Innovative Values:

Innovation Point 1: Integrated Signal Conditioning and Isolation. The DS200SHVMG1AFE is not a passive connector block. It incorporates active and passive components to buffer, filter, and isolate signals. It protects sensitive control-level signals (e.g., +/-10V command) from the electrical noise generated by high-power amplifier stages nearby. This isolation ensures the command signal reaching the final power amplifier is clean and accurate, which is absolutely critical for stable, jitter-free servo valve operation.

Innovation Point 2: Centralized I/O Hub for Enhanced Serviceability. This board consolidates all critical interconnections for the servo loop—control inputs, feedback returns, and interlock signals—onto a single, accessible board. This design philosophy drastically simplifies wiring, testing, and troubleshooting. A technician can probe test points, measure signals, or verify relay status directly on this one board, rather than tracing wires through an entire cabinet, significantly reducing Mean Time To Repair (MTTR).

Innovation Point 3: Robust Design for Mission-Critical Reliability. Engineered for a 24/7 power generation environment, the DS200SHVMG1AFE uses industrial-grade components and is built to withstand the temperature cycles and vibration inherent in a turbine control cabinet. Its design focuses on long-term contact integrity in connectors and stable performance of onboard conditioning circuitry. This robustness minimizes drift and intermittent connections, which are primary causes of unpredictable control behavior in analog servo systems.

Application Cases and Industry Value:

A midwestern power plant experienced recurring, unexplained trips on a GE Frame 6B gas turbine during startup. The trips were linked to a “servo drive fault” alarm. Intermittent signal dropouts on the LVDT feedback circuit were suspected. The maintenance team traced the issue to a failing signal conditioning component on the DS200SHVMG1AFE I/O board. The aging component caused sporadic feedback loss, which the protective system interpreted as a valve failure. Replacing the entire DS200SHVMG1AFE board (a faster and more reliable fix than component-level repair) resolved the intermittent fault completely. The plant superintendent noted: “Replacing the DS200SHVMG1AFE was the definitive fix. We eliminated the ghost trips that had plagued our starts for months. The unit’s start reliability is now back at 100%, which is crucial for our peaking duty and grid support obligations.”

Related Product Combination Solutions:

Servo Drive Assembly (e.g., DS200SDCCG1AF): The complete drive unit that houses the DS200SHVMG1AFE board as its core I/O interface.

Servo Valve (e.g., MOOG, ATOS, WOODWARD): The final control element (fuel valve, IGV actuator) that is positioned by the drive assembly controlled via the DS200SHVMG1AFE.

LVDT/RVDT Position Feedback: The linear/rotary variable differential transformer that provides real-time valve position feedback to the DS200SHVMG1AFE board.

Mark V Control Module (e.g., DS200TCPDG1): The main turbine controller that generates the positioning command sent to the servo drive assembly containing the DS200SHVMG1AFE.

GE ToolboxST Software: The engineering tool used to configure, monitor, and diagnose the Mark V system, including parameters and alarms related to the servo loop managed by the DS200SHVMG1AFE.

Installation, Maintenance, and Full-Cycle Support:

Installation of the DS200SHVMG1AFE board requires the servo drive unit to be de-energized and isolated following strict Lock-Out/Tag-Out (LOTO) procedures. The board is secured within the drive assembly and connected via multiple harnesses. Critical steps include careful handling to avoid electrostatic discharge (ESD) damage, ensuring all connectors are fully seated and locked, and verifying that no wiring is pinched or strained during reassembly. A thorough functional test of the servo loop should be performed after replacement.

Preventive maintenance involves periodic visual inspections of the board for signs of overheating, cracked solder joints, or corrosion on connectors. Monitoring system alarms for any recurring servo-related warnings is also key. When troubleshooting a suspected drive issue, the DS200SHVMG1AFE is a focal point for taking signal measurements to isolate whether a problem originates from the controller, the wiring, the feedback device, or the power stage. We provide full support for this process, from supplying factory-tested or certified refurbished DS200SHVMG1AFE boards to providing wiring diagrams and guidance for signal verification. Our goal is to ensure you restore your turbine’s precise control reliably and efficiently.

Contact us for immediate sourcing and technical assistance for the GE DS200SHVMG1AFE board to maintain the precision and reliability of your Mark V turbine control system.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: