Description

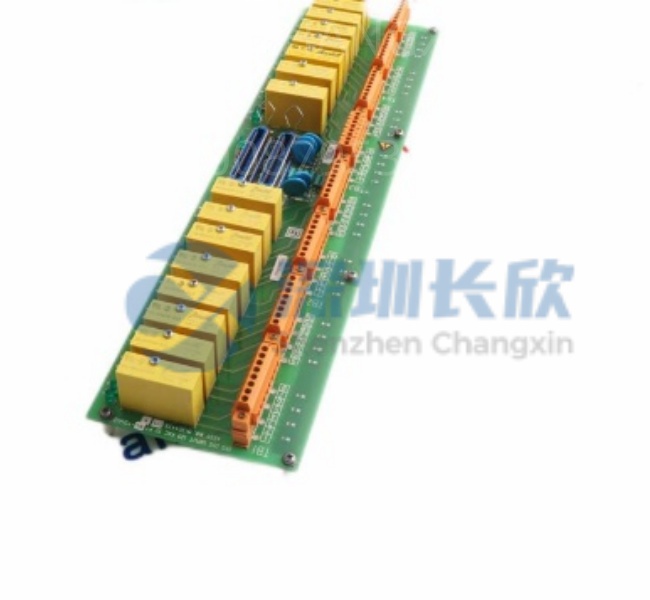

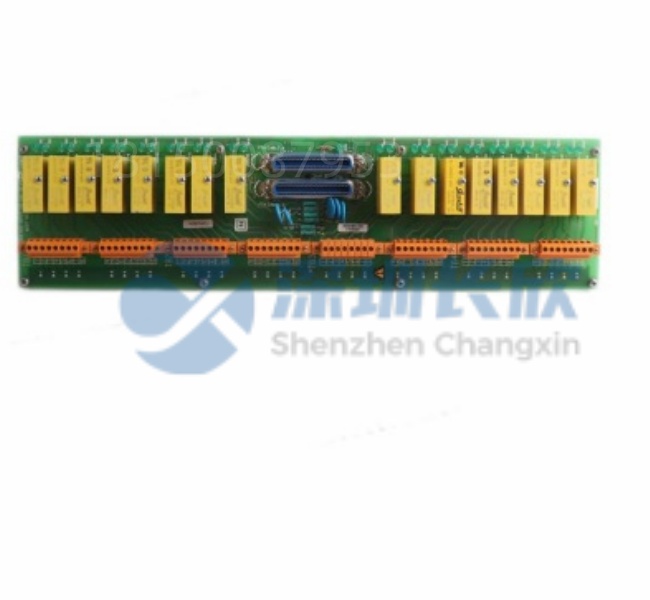

The HONEYWELL MC-TDIA12 (P/N: 51304439-175) is a high-performance, 12-channel analog input (AI) module designed for Honeywell’s Experion® PKS R500/R600 systems using the Fault-Tolerant Ethernet Baseplate (FTEB) architecture. It accepts industry-standard 4–20 mA signals from smart field transmitters and provides full transparent HART® communication pass-through on all channels—enabling real-time device diagnostics, calibration verification, and asset management without disrupting process data. Engineered for mission-critical applications, the MC-TDIA12 delivers metrology-grade accuracy, robust isolation, and seamless integration into modern DCS environments.

Application Scenarios

At a Middle Eastern gas processing facility, inconsistent pressure readings across compressor trains were causing inefficient anti-surge control and frequent false trips. Legacy analog cards lacked HART access, forcing technicians to perform manual transmitter checks during costly shutdowns. After deploying the HONEYWELL MC-TDIA12 51304439-175. engineers gained both ultra-stable 4–20 mA acquisition (±0.05% accuracy) and live HART data streamed directly to Emerson AMS Device Manager via Experion PKS. Within weeks, they identified a transmitter with internal damping misconfiguration—correcting it remotely. Since installation, measurement reliability has improved by 95%, and field maintenance visits dropped by over 60%. For process teams, the MC-TDIA12 transformed analog inputs from passive signals into intelligent, actionable assets.

Parameter

表格

Note: Requires compatible Field Termination Assembly (FTA), such as FTA-AI-12 or FTA-AI-16. for fused, shielded field wiring.

Technical Principles and Innovative Values

Innovation Point 1: True Multi-Channel HART Multiplexing

Unlike older modules that support HART on only one channel at a time, the MC-TDIA12 uses advanced digital signal processing to allow concurrent or sequential HART communication across all 12 channels—without interrupting 4–20 mA scanning or requiring external multiplexers.

Innovation Point 2: Precision Metrology in Industrial Packaging

The module employs low-drift, temperature-compensated amplifiers and high-stability reference circuits, maintaining ±0.05% accuracy across its full temperature range—critical for custody transfer, reactor control, and emissions monitoring.

Innovation Point 3: Predictive Diagnostics per Channel

Each channel continuously monitors for open circuit, short circuit, out-of-range signals, and abnormal current draw. Combined with HART device status (e.g., “Sensor Alert”), the MC-TDIA12 enables predictive maintenance before failures impact production.

Innovation Point 4: Seamless Brownfield Migration

The MC-TDIA12 fits the same FTEB chassis used in legacy HLAI upgrades, allowing facilities to modernize I/O performance without rewiring cabinets—reducing capital cost and project risk during DCS migrations.

Application Cases and Industry Value

During a revamp of a European ethylene cracker’s quench tower controls, the engineering team replaced aging 8-channel analog cards with the HONEYWELL MC-TDIA12 51304439-175 to increase density and add HART visibility. Post-commissioning, HART data from 120+ smart transmitters flowed into AMS Suite, enabling remote zero/span validation and early detection of plugged impulse lines. One instance caught a failing differential pressure cell 48 hours before it would have triggered a low-level trip—saving an estimated €750.000 in avoided downtime. Maintenance now performs 80% of transmitter health checks from the control room. The MC-TDIA12 didn’t just digitize analog—it redefined operational excellence.

Related Product Combination Solutions

Honeywell FTEB Chassis (e.g., DC-TFB402) – Native host platform for MC-TDIA12

FTA-AI-12 / FTA-AI-16 – Field terminal assemblies with fuse protection and surge suppression

Honeywell C300 Controller – Primary logic solver; routes HART data to asset management systems

Emerson AMS Device Manager – Leverages HART pass-through for predictive maintenance

Honeywell MC-TDID16 – 16-channel discrete input module (complementary I/O)

Honeywell MC-TDOA08 – 8-channel analog output module for closed-loop control

Honeywell Experion PKS R600 – Full DCS environment with native support for MC-TDIA12 diagnostics

This ecosystem creates a closed-loop, intelligent measurement layer where the MC-TDIA12 serves as the trusted gateway between field devices and enterprise intelligence.

Installation, Maintenance, and Full-Cycle Support

Installation: Insert the MC-TDIA12 into an FTEB chassis powered by redundant HONEYWELL -80363975-100 power supplies. Connect field wiring via FTA-AI-12. ensuring proper shielding and grounding. Configure channels in Control Builder for engineering units, alarm limits, and HART polling strategy. No manual calibration is required—factory trim is retained for life under normal conditions.

Maintenance: Real-time channel status (OK, Open Wire, Overrange) appears on front-panel LEDs and in the Experion HMI. HART alerts flag device-level issues like sensor degradation or configuration drift. If replacement is needed, hot-swap capability allows removal/insertion without powering down the rack—configuration is automatically restored.

Every HONEYWELL MC-TDIA12 51304439-175 we supply undergoes full functional testing with live 4–20 mA and HART signals across temperature extremes. Units include traceable calibration records and are backed by expert technical support and a 12-month warranty.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: