Description

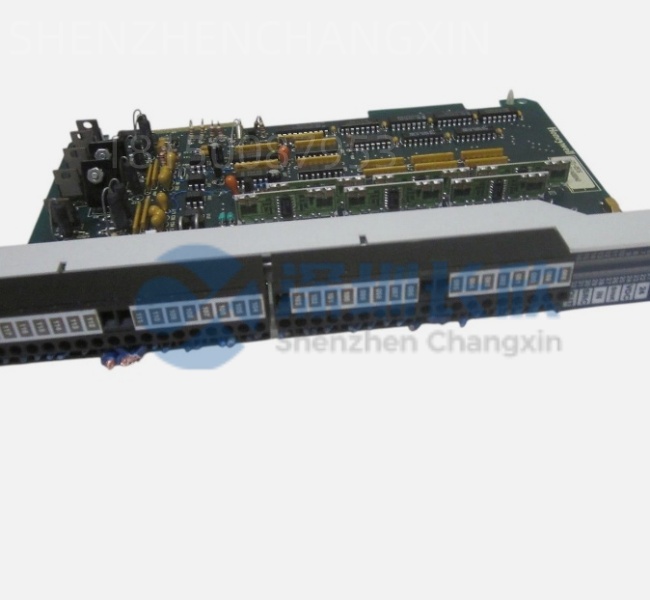

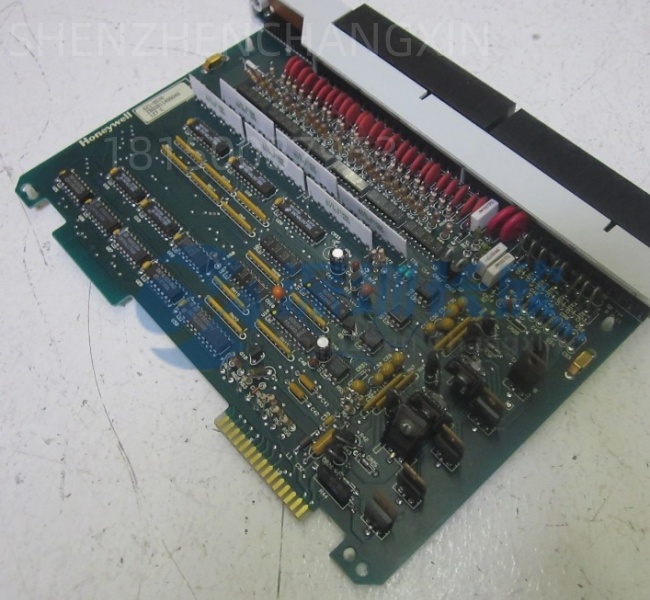

The HONEYWELL 621-0576 is an 8-channel discrete (digital) input module engineered for Honeywell’s TDC 3000. TotalPlant Solutions (TPS), and backward-compatible with Experion PKS HLAI-based systems. Designed to interface with field devices such as limit switches, pushbuttons, relay contacts, and PLC outputs, it converts dry or powered contacts into reliable digital signals for process logic and safety interlocks. The HONEYWELL 621-0576 combines rugged industrial design with intelligent diagnostics—ensuring signal integrity in electrically noisy environments like refineries, power plants, and heavy manufacturing.

Application Scenarios

At a U.S. Midwest chemical plant undergoing a phased DCS modernization, legacy discrete cards in the TPS system were failing due to ground loops and EMI from nearby variable-frequency drives. Technicians faced weekly false trips on reactor agitator run-status inputs. After replacing aging modules with genuine HONEYWELL 621-0576 units, the team observed immediate stability: each channel’s optical isolation and wide hysteresis eliminated chatter, while front-panel LEDs allowed instant fault localization. During a subsequent motor control center upgrade, one channel correctly flagged a stuck contactor—preventing a potential overpressure event. For reliability engineers, the HONEYWELL 621-0576 restored trust in binary data—the foundation of all safety logic.

Parameter

表格

Note: Requires compatible Field Termination Assembly (FTA), such as FTA-DI-08. for fused field wiring and surge protection.

Technical Principles and Innovative Values

Innovation Point 1: True Optical Isolation per Channel

Unlike cost-reduced modules that share grounds, the HONEYWELL 621-0576 uses individual optocouplers for each input—preventing ground loops and cross-channel interference in mixed-voltage panels.

Innovation Point 2: Wide Hysteresis for Contact Debouncing

Built-in Schmitt-trigger circuitry ensures clean switching even with slow or arcing mechanical contacts—critical for valve position feedback or emergency stop circuits where signal jitter could trigger false logic.

Innovation Point 3: Backward Compatibility Across Generations

The HONEYWELL 621-0576 fits directly into legacy TPS HLAI racks and works with existing FTAs, enabling brownfield sites to extend system life without rewiring—a key advantage during staged migrations to Experion PKS.

Innovation Point 4: Diagnostic Transparency

Each channel’s LED reflects real-time field status, not just internal logic. Combined with TPS or Experion alarm tags, the HONEYWELL 621-0576 turns troubleshooting from guesswork into a visual science.

Application Cases and Industry Value

During a turnaround at a Canadian oil sands upgrader, the firewater pump skid’s start-permission logic kept failing due to erratic discrete signals from local panel switches. Investigation revealed that non-isolated third-party replacements had been installed years earlier. The team swapped in authentic HONEYWELL 621-0576 modules across all safety interlock racks. Within hours, all inputs stabilized—even during simultaneous pump startups that induced >50 V transients on shared grounds. Over the next year, zero discrete-related safety system faults occurred. Maintenance reported a 60% reduction in diagnostic time. The HONEYWELL 621-0576 proved that in safety-critical systems, every bit must be bulletproof.

Related Product Combination Solutions

Honeywell HLAI Chassis: Native host platform for HONEYWELL 621-0576 in TPS and early Experion systems

FTA-DI-08: 8-channel fused terminal block assembly—provides surge protection and field wiring for HONEYWELL 621-0576

Honeywell 621-0577: 8-channel discrete output module—complements HONEYWELL 621-0576 for full I/O loops

Honeywell TPS GUS (Global User Station): Operator interface—displays real-time status from HONEYWELL 621-0576 channels

Honeywell Experion Server: Modern migration target—supports HONEYWELL 621-0576 via HLAI emulation

Honeywell 51195066-100: Analog input module—often deployed alongside HONEYWELL 621-0576 in hybrid I/O cabinets

Phoenix Contact MINI MCR-SL-R-UI-45: Signal conditioner—for interfacing non-standard voltages with HONEYWELL 621-0576

This portfolio ensures seamless integration, whether maintaining legacy TPS or bridging to next-generation control.

Installation, Maintenance, and Full-Cycle Support

Installing the HONEYWELL 621-0576 requires insertion into an HLAI or TPS I/O chassis with proper backplane power. Field wiring connects through a compatible FTA (e.g., FTA-DI-08), which provides fused, shielded termination and optional transient suppression. No configuration jumpers are needed—channel behavior is defined in the TPS or Experion database.

Maintenance is exceptionally straightforward. During routine rounds, technicians verify input status via the bright front-panel LEDs. If a channel fails to respond, they first check the FTA fuse, then use a multimeter to confirm field voltage—thanks to the clear separation between field and logic sides. Module replacement takes seconds: simply pull the handle and insert a spare. Configuration is retained in the controller, so no reprogramming is required.

Every HONEYWELL 621-0576 we supply undergoes functional testing with live discrete signals under EMI stress and thermal cycling. Units include test reports and are guaranteed compatible with your specific TPS release or Experion version. Backed by expert technical support and rapid global logistics, we ensure your binary signals remain the bedrock of safe, reliable automation.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: